Transmission box with gear clutch

A clutch and transmission box technology, applied in the transmission box field, can solve the problems of increasing the volume of the gearbox, failing to achieve the clutch effect, and unusable pulley clutches, etc., to achieve reduced impact, good running stability, and favorable power distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

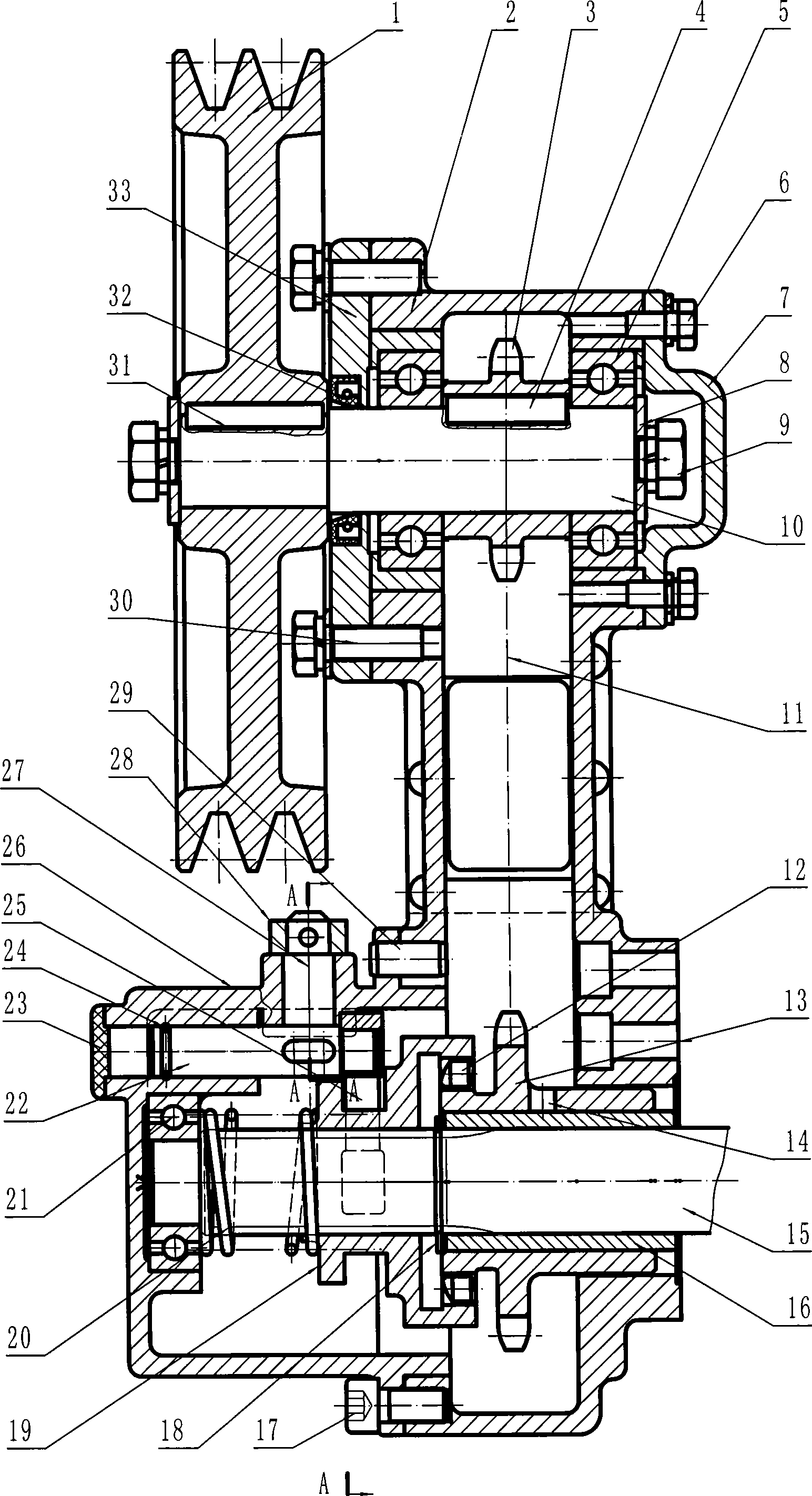

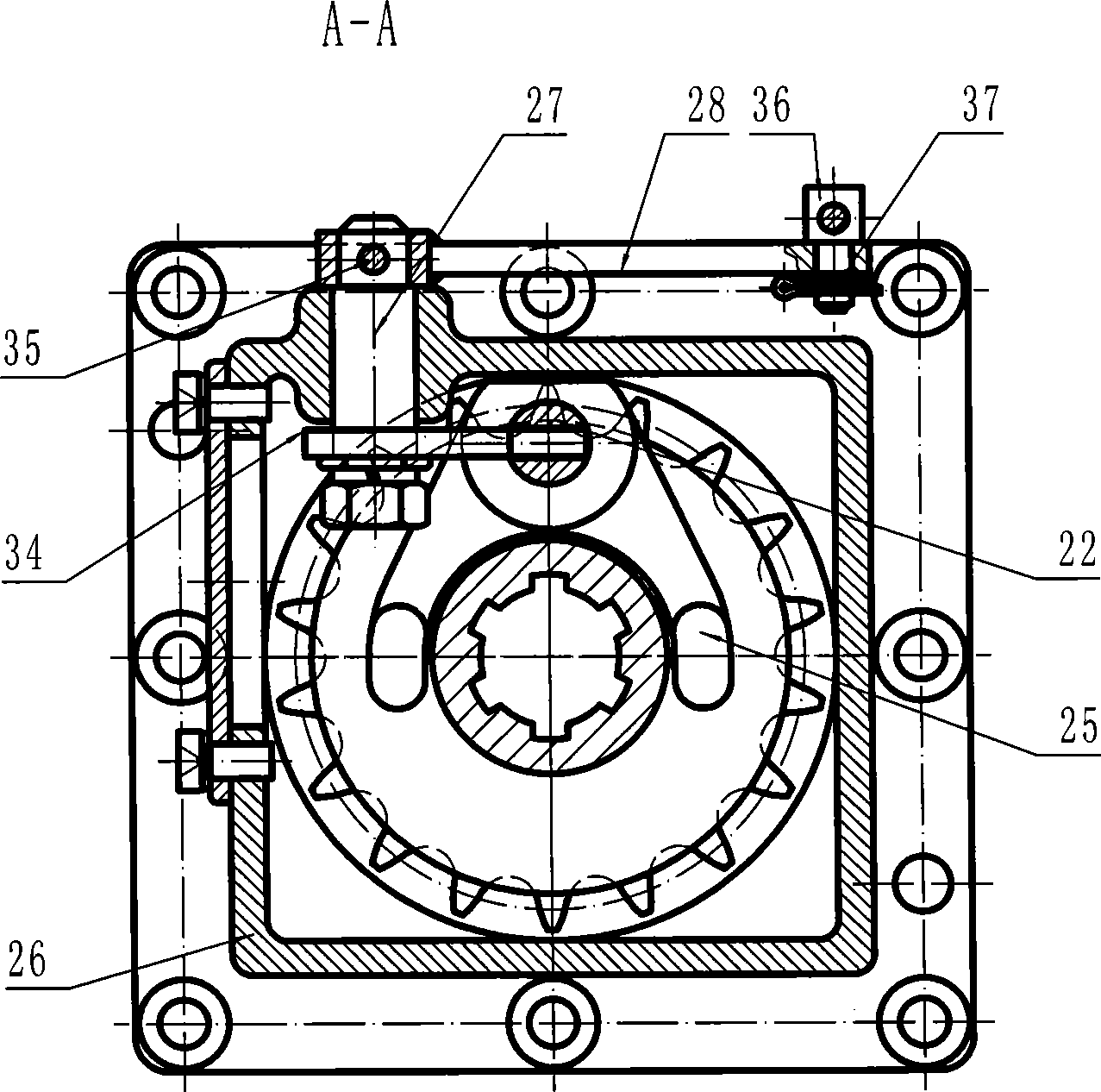

Embodiment 1

[0018] A chain transmission box with a toothed clutch, which includes a box body 2, the input shaft 10 is erected on the left and right side walls of the box body 2 through a set of bearings 5, and the driving sprocket 3 is arranged on the input side of the box body 2. On the shaft 10, the driving sprocket 3 is radially fixed to the input shaft 10 through the key 4. A shaft end cover 7 and a shaft cover 33 are respectively arranged on the outside of a set of bearings 5, the shaft end cover 7 is fixed on the box body 2 by a number of screws 6, the shaft cover 33 is fixed on the box body 2 by a number of screws 30, the shaft cover 33 is provided with a rotating lip seal ring 32 outside the shaft hole. The part of the input shaft 10 protruding from the casing 2 is provided with a driven pulley 1, and the driven pulley 1 is radially fixed to the input shaft 10 through a key 31. Both ends of the input shaft 10 are respectively fixed with retaining rings 8 by screws 9 .

[0019] O...

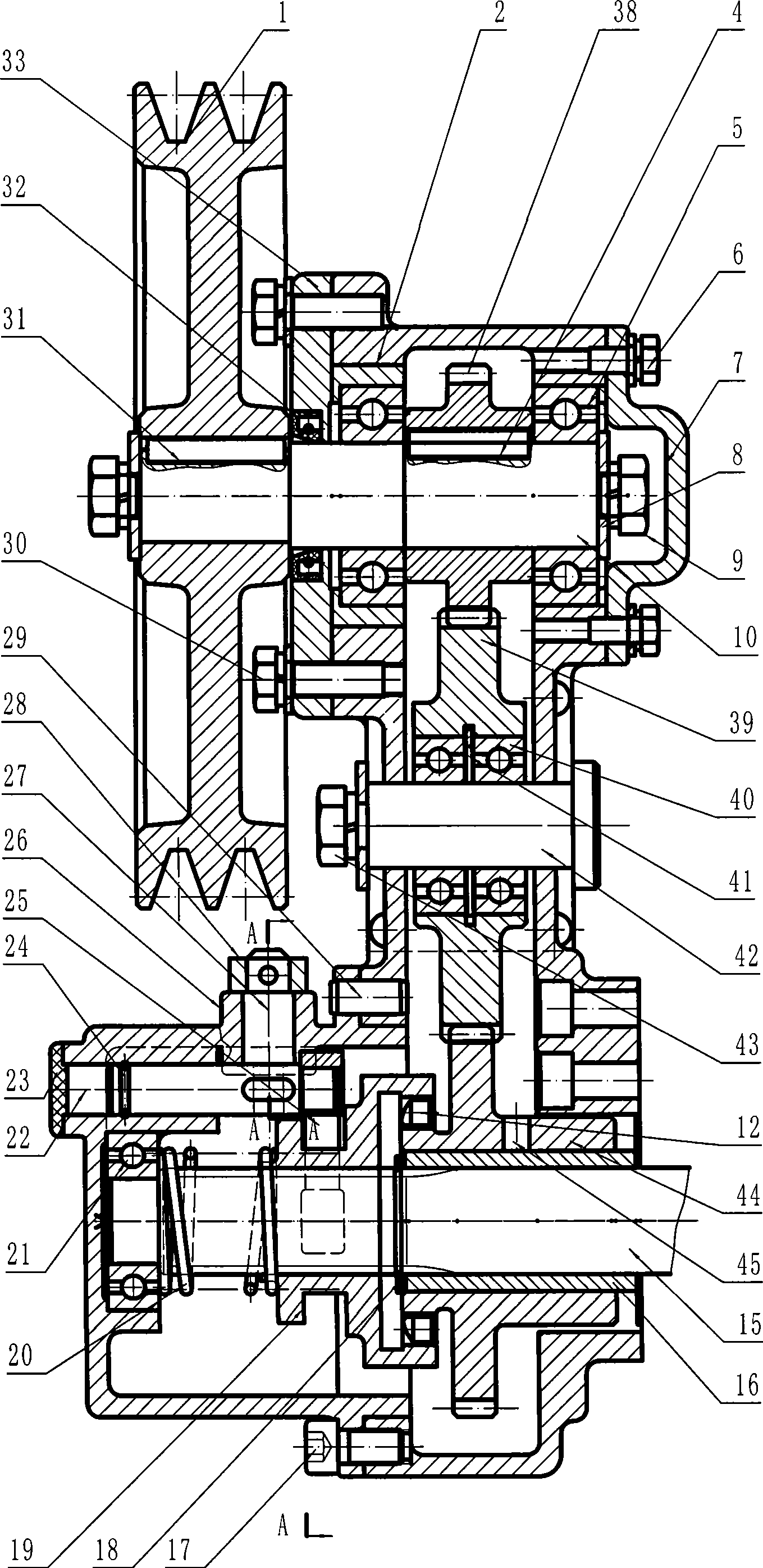

Embodiment 2

[0023] A gear transmission box with a toothed clutch, which includes a box body 2, the input shaft 10 is erected on the left and right side walls of the box body 2 through a set of bearings 5, and the driving gear 38 is arranged on the input shaft in the box body 2 10, the driving gear 38 is radially fixed with the input shaft 10 through the key 4. A shaft end cover 7 and a shaft cover 33 are respectively arranged on the outside of a set of bearings 5, the shaft end cover 7 is fixed on the box body 2 by a number of screws 6, the shaft cover 33 is fixed on the box body 2 by a number of screws 30, the shaft cover 33 is provided with a rotating lip seal ring 32 outside the shaft hole. The part of the input shaft 10 protruding from the casing 2 is provided with a driven pulley 1, and the driven pulley 1 is radially fixed to the input shaft 10 through a key 31. Both ends of the input shaft 10 are respectively fixed with retaining rings 8 by screws 9 .

[0024] One end of the outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com