Low pressure drop floating type gas phase media water-sealed valve

A floating, low pressure drop technology, applied in the lift valve, valve details, valve device and other directions, can solve the problems of large pressure drop, high price, complex structure, etc., to achieve the effect of pressure drop, low cost and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

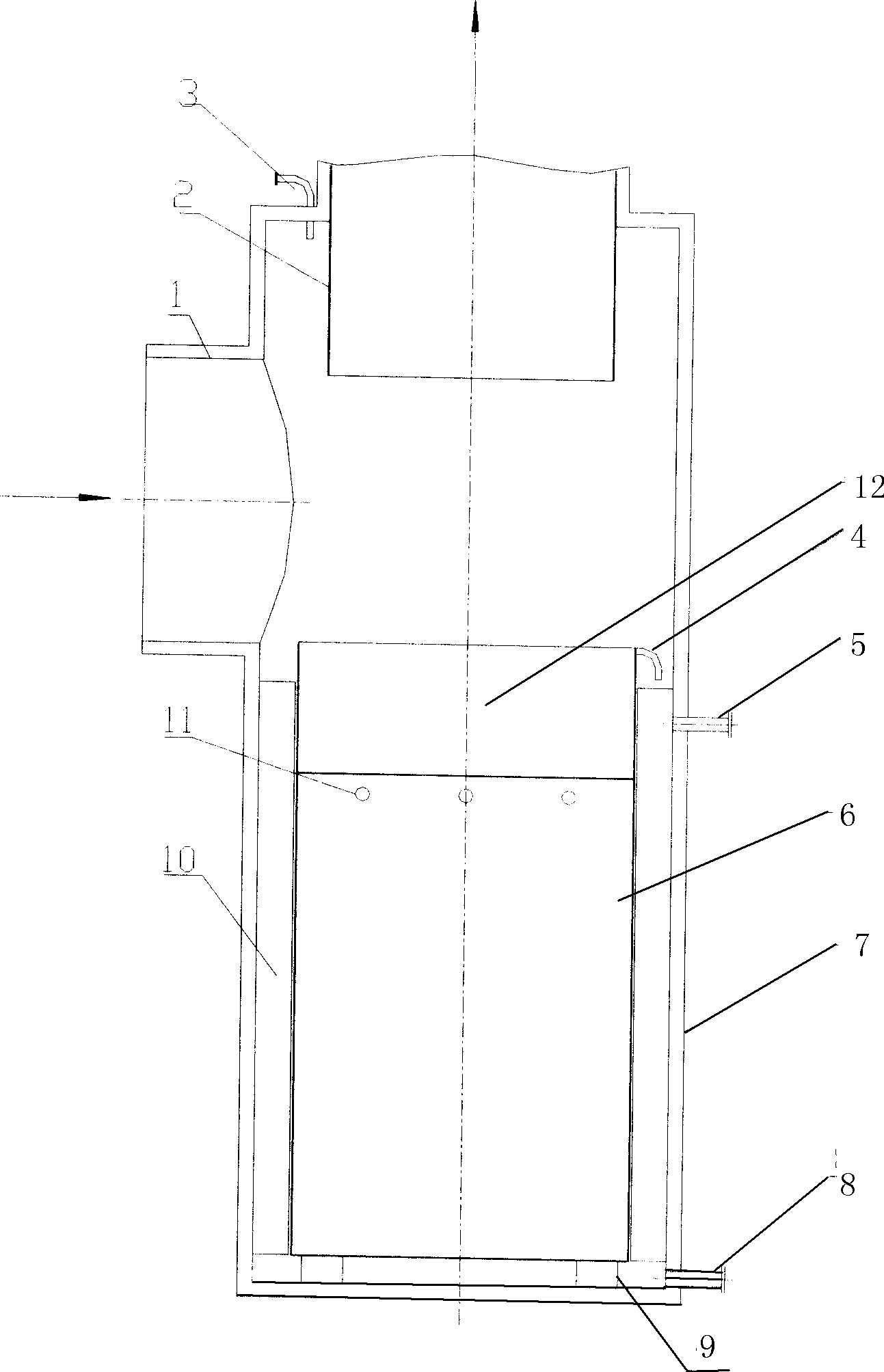

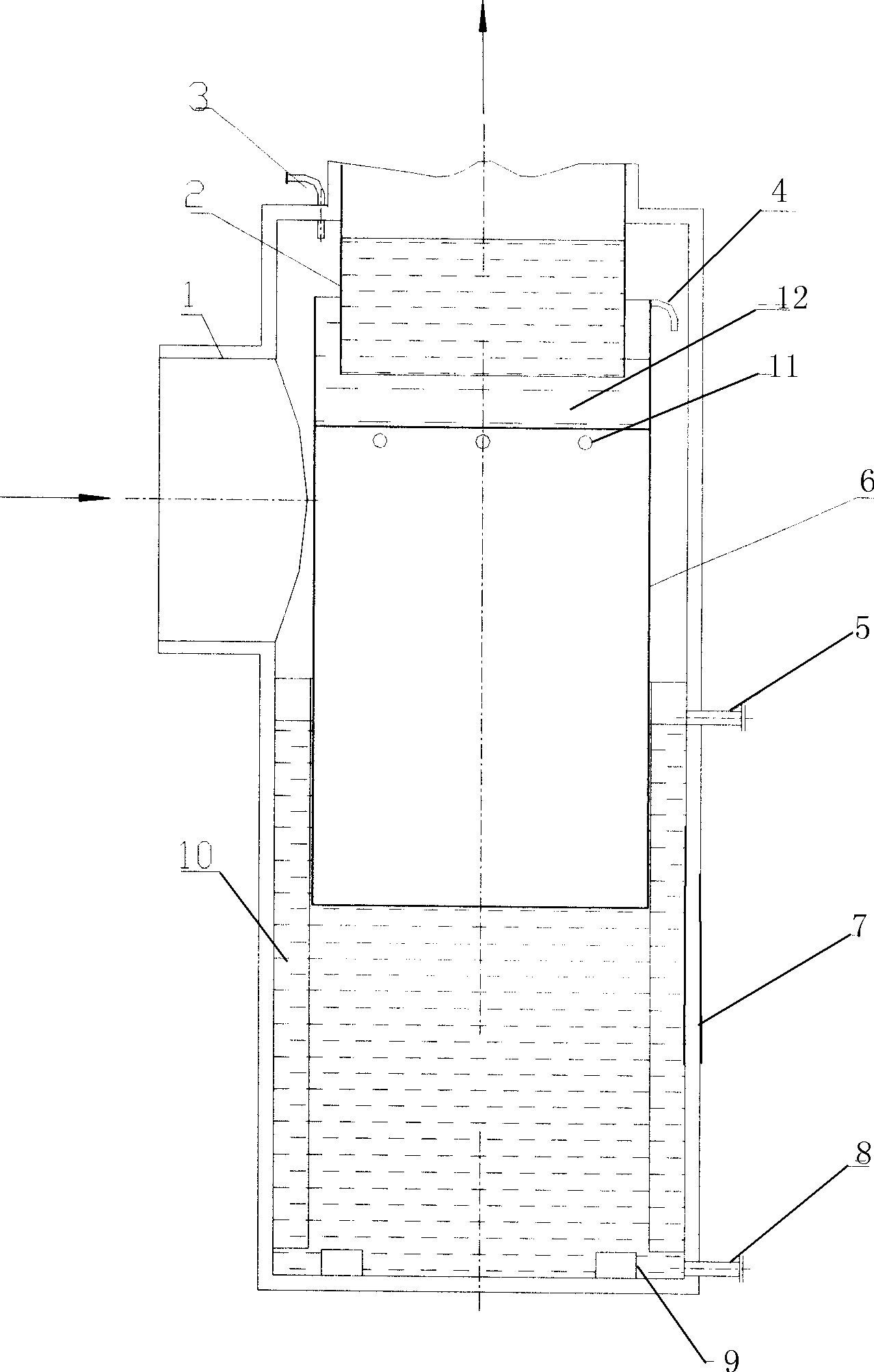

[0016] The present invention will be further described below in conjunction with accompanying drawing:

[0017] A low-pressure-drop floating gas-phase medium water-sealed valve, which includes a gas inlet pipe (1), a gas outlet pipe (2), an overflow outlet (5), a valve body (7), and a water inlet and outlet (8). The valve body (7) is provided with a floating spool (6) that can float up and down, and the upper part of the floating spool (6) is provided with a sealed water tank (12) and an inner overflow port (4). 6) The wall is provided with ventilation holes (11). The lower part of the valve body (7) is provided with a supporting pad iron (9). A guide rail (10) for guiding the floating valve core (6) to move up and down accurately is provided between the valve body (7) and the floating valve core (6); a water seal water inlet ( 3).

[0018] When in use, if it is necessary to cut off the gaseous medium, the water inlet and outlet (8) start to enter water, and when the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com