Color filter slice, method for manufacturing the same and liquid crystal display device

A manufacturing method and technology of color filters, which are applied in the direction of optical filters, photographic plate-making process of patterned surface, instruments, etc., can solve the problems of easy degradation and unevenness of image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

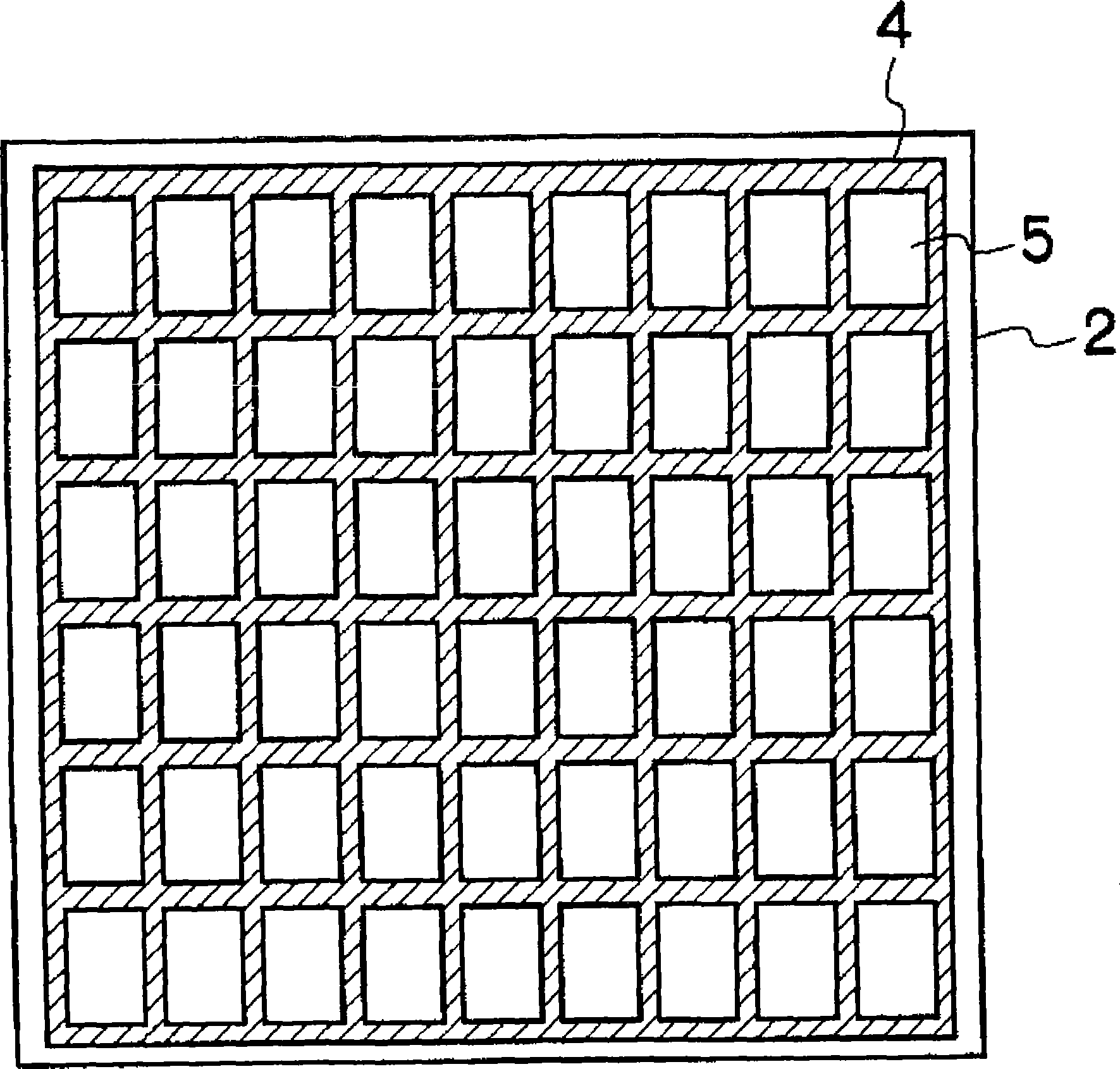

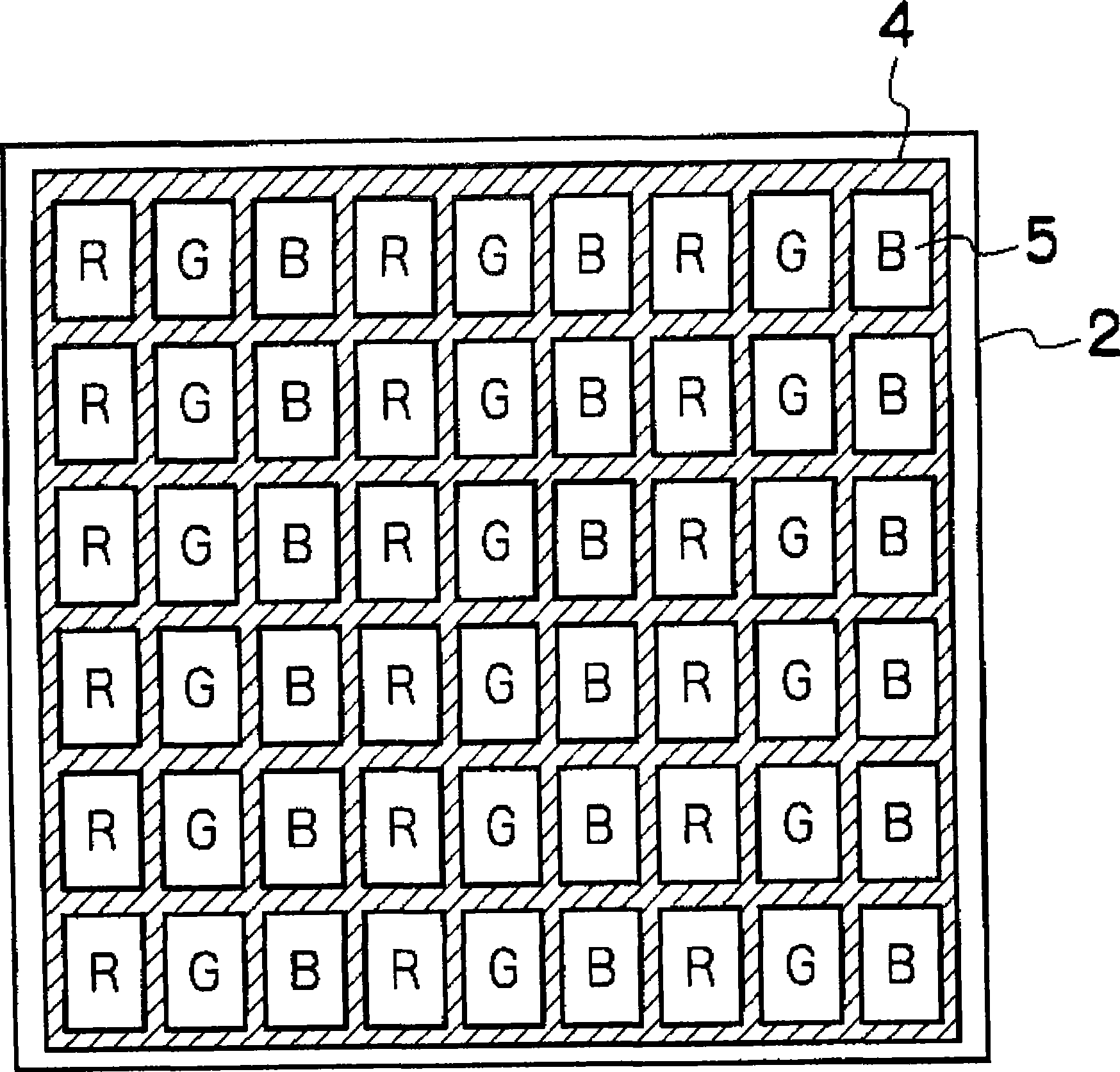

[0022] The present invention will be described below with reference to the accompanying drawings.

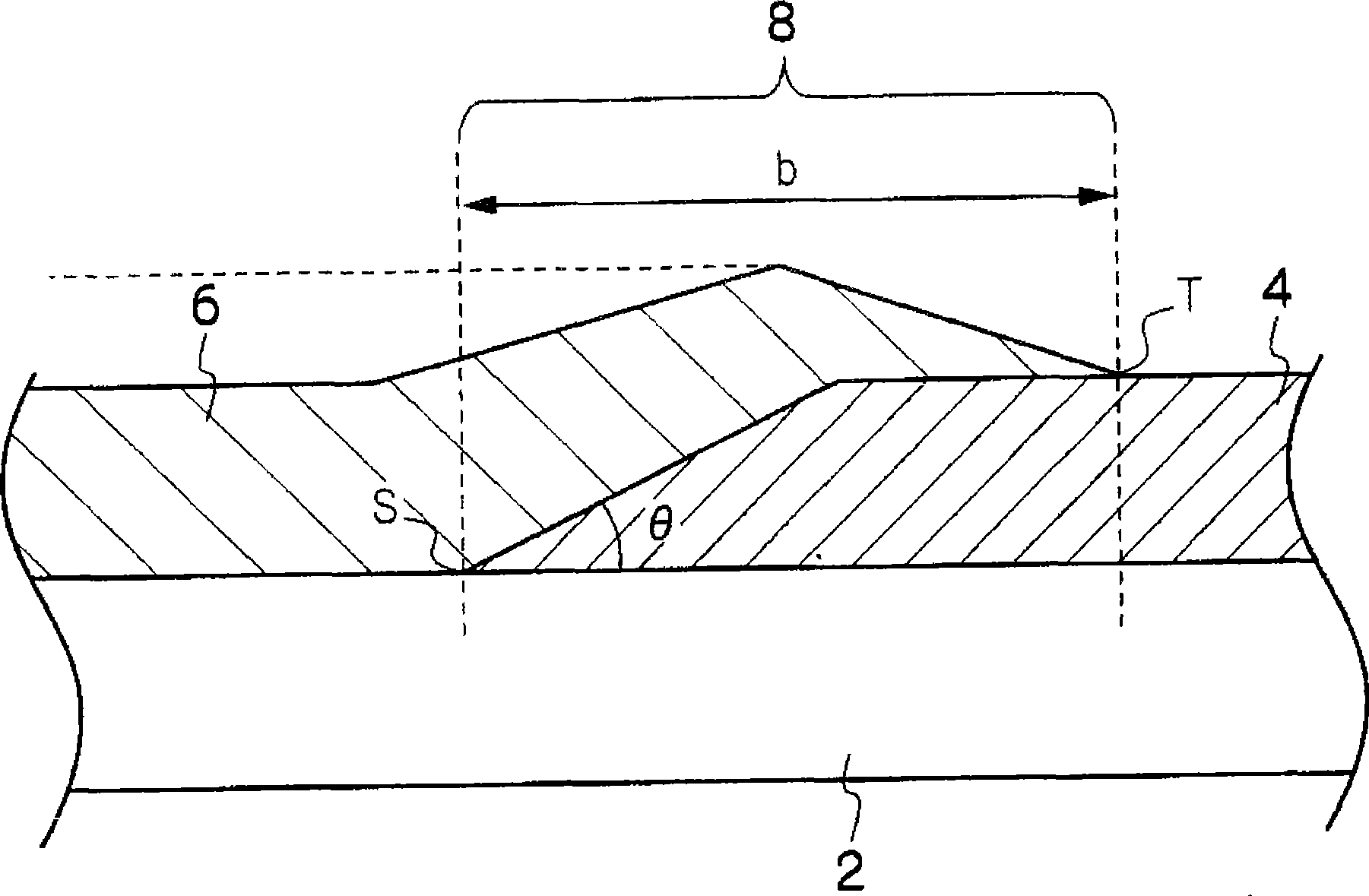

[0023] In the color filter of the present invention, a black matrix and coloring pixels of two or more colors separated by the black matrix are formed on the substrate, the contrast ratio is more than 5000, and the angle θ formed by the side walls and the bottom surface of the partition walls constituting the black matrix is 10. ° to 35°, and the relative standard deviation of the angle θ is 0.15 or less.

[0024] Here, the angle (theta) (it is suitably called "inclination angle (theta) of a side surface") which the side surface and the bottom surface of the partition which comprise a black matrix form is demonstrated.

[0025] image 3 and Figure 4 It is a figure which shows an example of the cross-sectional shape of the partition of the black matrix (photosensitive dark color composition layer) which comprises the color filter in this invention.

[0026] The inclination ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average particle size | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap