Wear-resistant collecting vat of charging centrifugal machine

A pusher centrifuge and collection tank technology, which is applied in the field of collection systems, can solve the problems of material particle crushing and collection tank wear, and achieve the effect of reducing particle crushing and solving serious wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

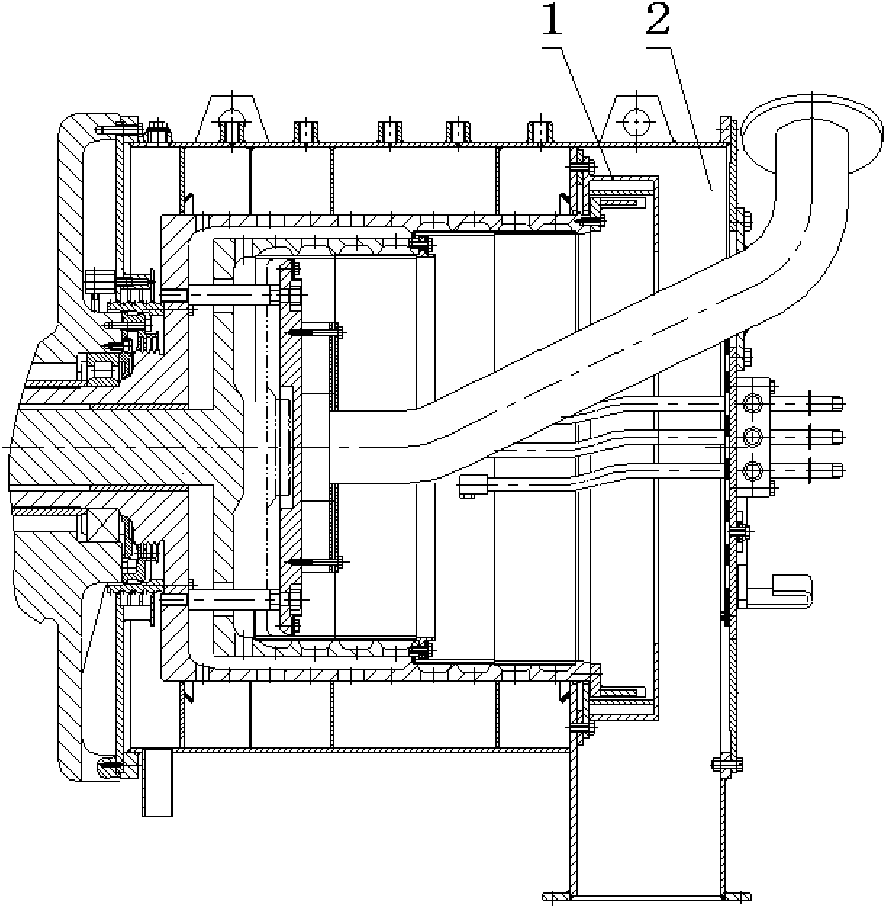

[0020] see figure 1 with figure 2 , the present embodiment comprises a pusher centrifuge collection system 2, a solid collection device 1, the solid collection device 1 is installed in the pusher centrifuge collection system 2, a U-shaped collection tank 4 is established in the solid collection device 1, and the collection A wear-resistant layer 3 is installed on the groove 4 lining.

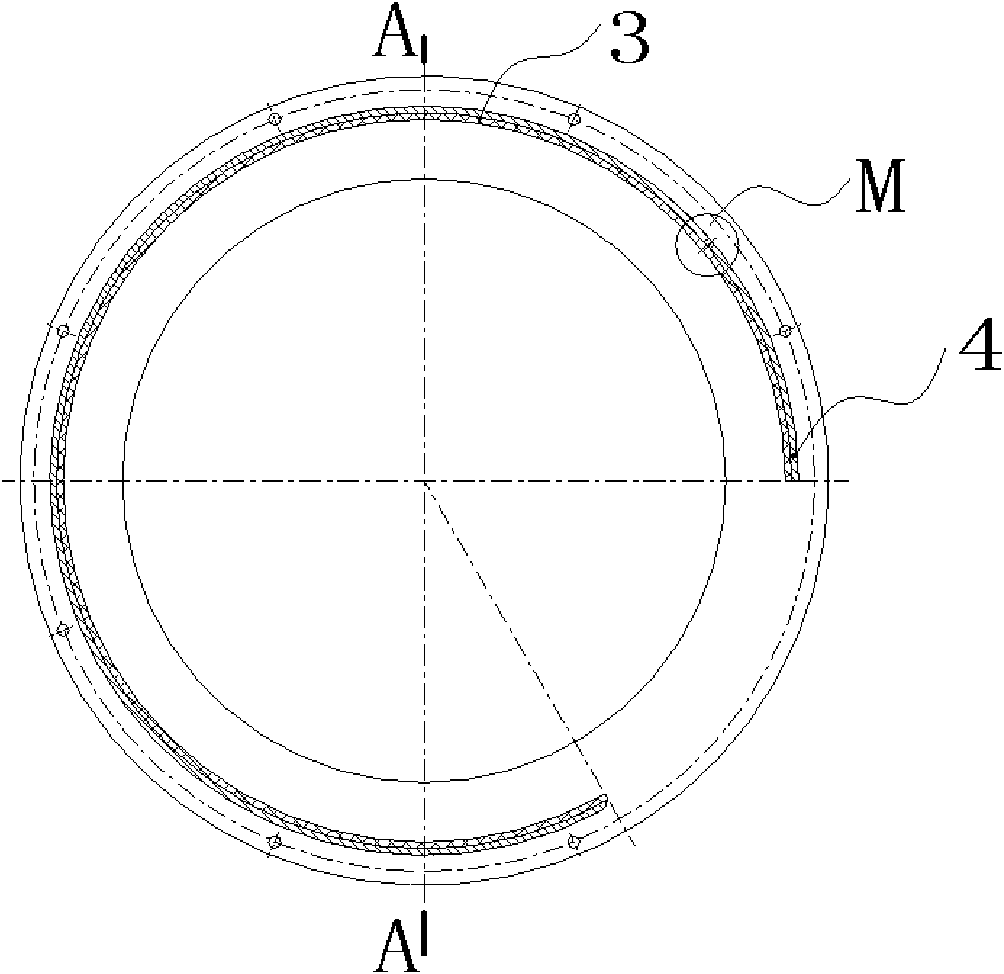

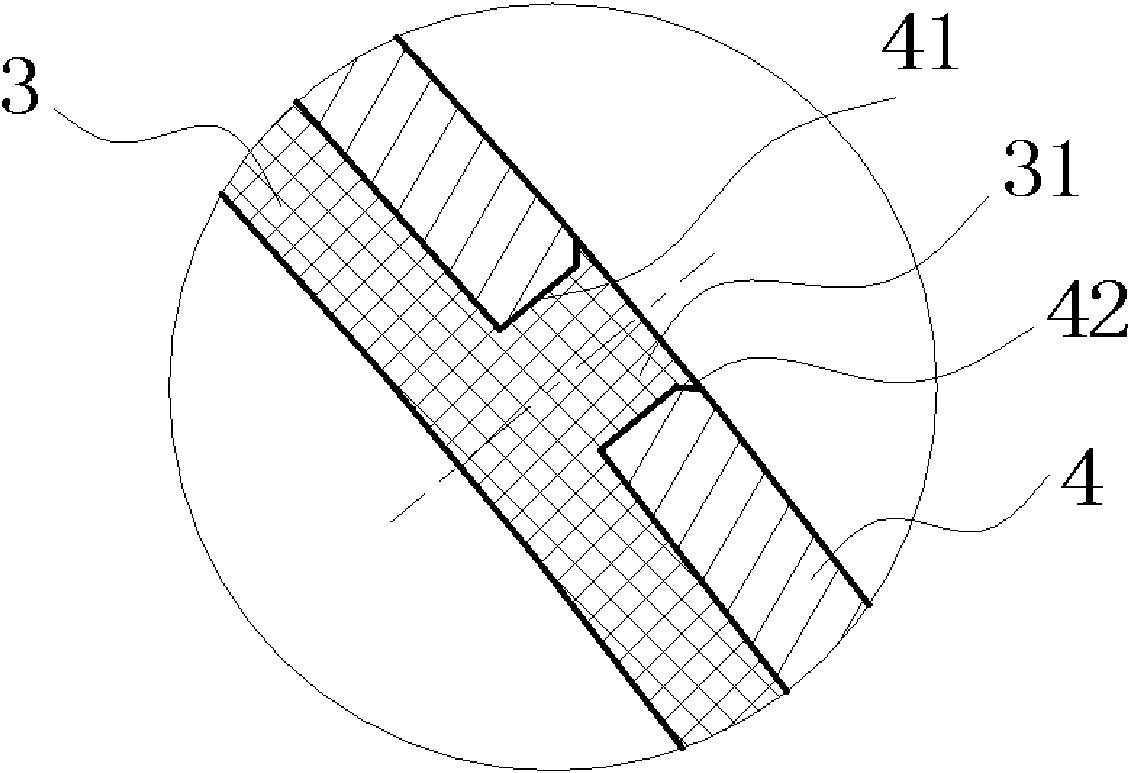

[0021] Such as image 3 , Figure 4 As shown, a number of circular small holes 41 are processed around the cylinder body of the collecting tank 4, and a protruding pin 31 corresponding to the small hole 41 is provided on the wear-resistant layer 3, and the hole end of each small hole 41 is provided with Chamfering 42, the end of lug 31 is flush with small hole 41, wear-resistant layer and cylinder body one-time inje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com