Bottom working roll transmission device of super wide lapping machine

A technology of transmission device and work roll, which is applied in the field of forging machinery, can solve the problems of long-term work of work roll under the influence, easy formation of misalignment of rolled sheets, and insufficient compact structure, etc., to achieve compact structure, enhanced transmission reliability, and structural reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

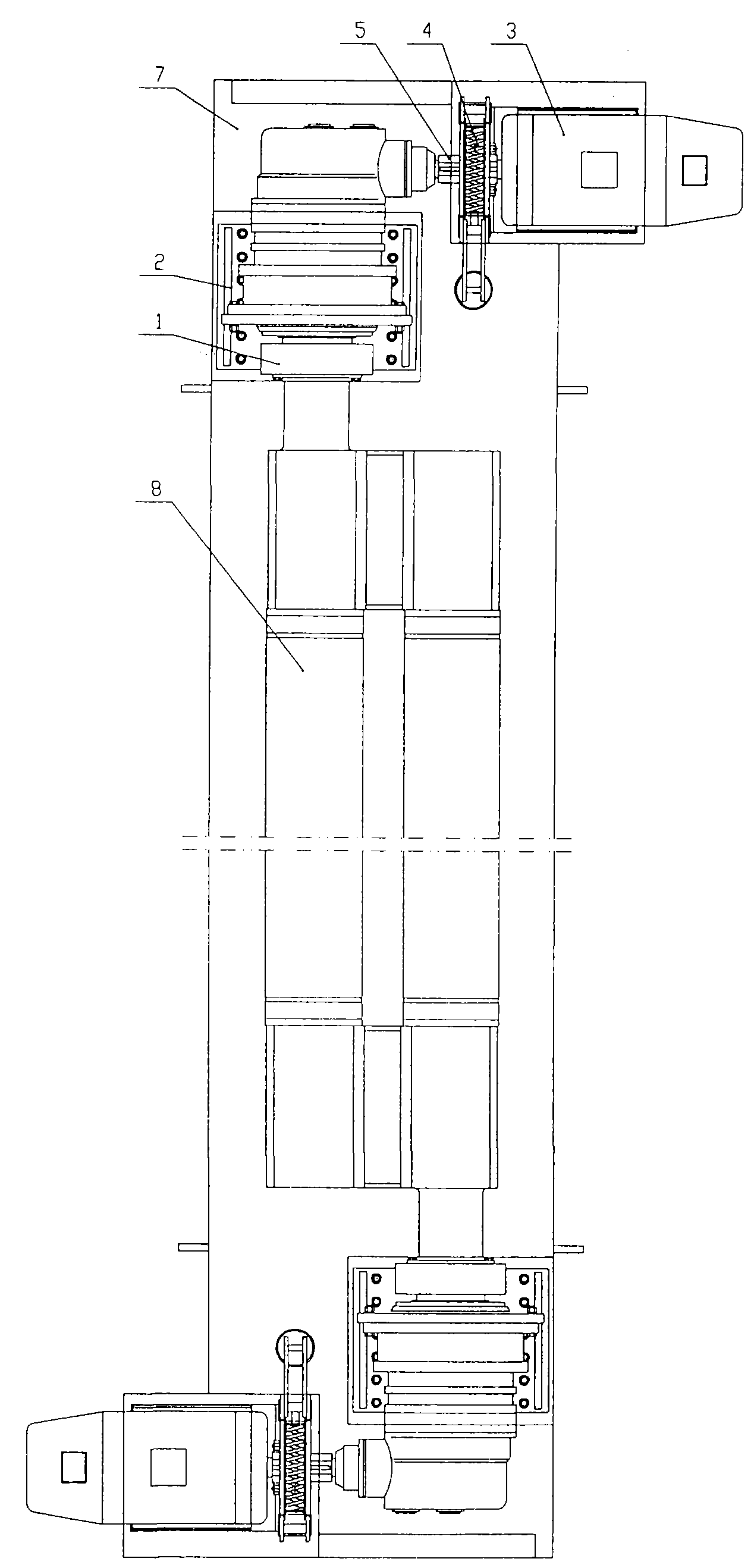

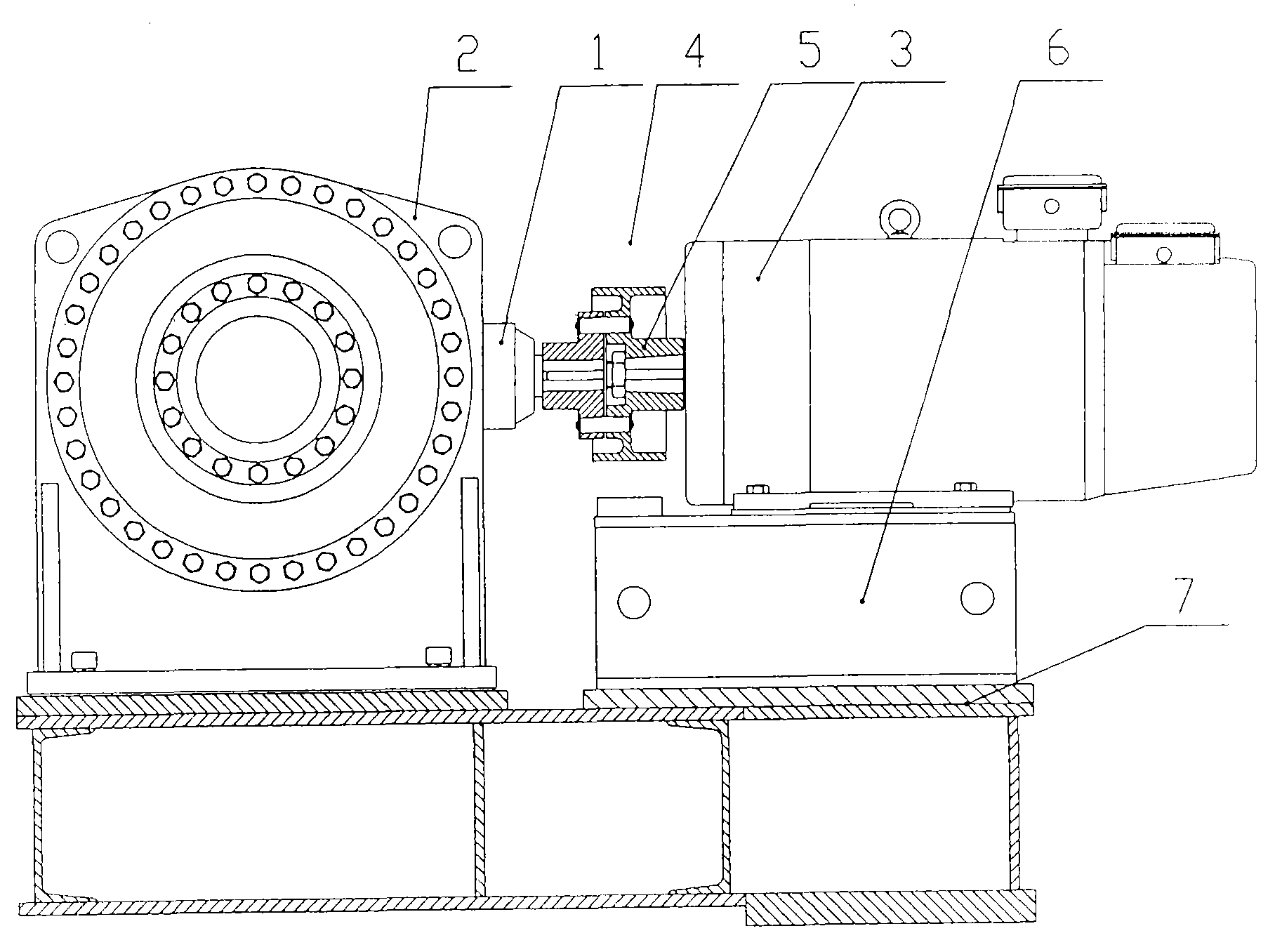

[0010] Such as figure 1 , 2 As shown, two lower work rolls 8 are respectively arranged on the bottom plate 7 through bearings, and a set of work roll power mechanisms are respectively arranged at both ends of the bottom plate 7 .

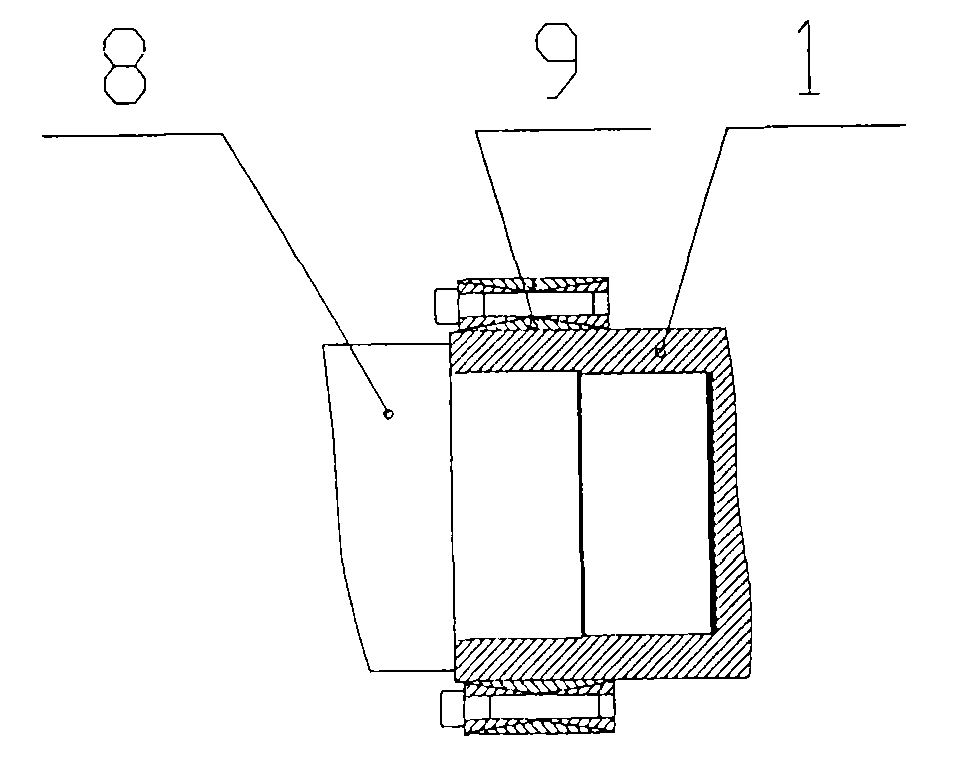

[0011] The power mechanism of the work roll is mainly composed of a motor 3, an elastic pin coupling 5, a reducer 2, and a brake 4. The motor 3 is supported on the bottom plate 7 through the motor base 6, and the reducer 1 is connected to the bottom plate 7 through the reducer support frame 2. Above, an elastic pin coupling 5 is connected between the output end of the motor 3 and the input end of the reducer 2 , and the brake 4 is connected to both ends of the elastic pin coupling 5 . The end of the output shaft of the reducer 1 is provided with a concentric inner hole, and one end of the lower work roll 8 is arranged in the inner hole, and an expansion disk 9 is arranged outside the output shaft of the reducer 1, and is clamped by the expansion di...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap