Reactor for microalgae outdoor breeding

A technology of reactor and microalgae, which is applied in the field of outdoor microalgae breeding reactors, can solve the problems of easy pollution of algae species, achieve the effects of increasing absorption rate, reducing cost, and avoiding serious pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with the best embodiment shown in the accompanying drawings, it will be further described in detail.

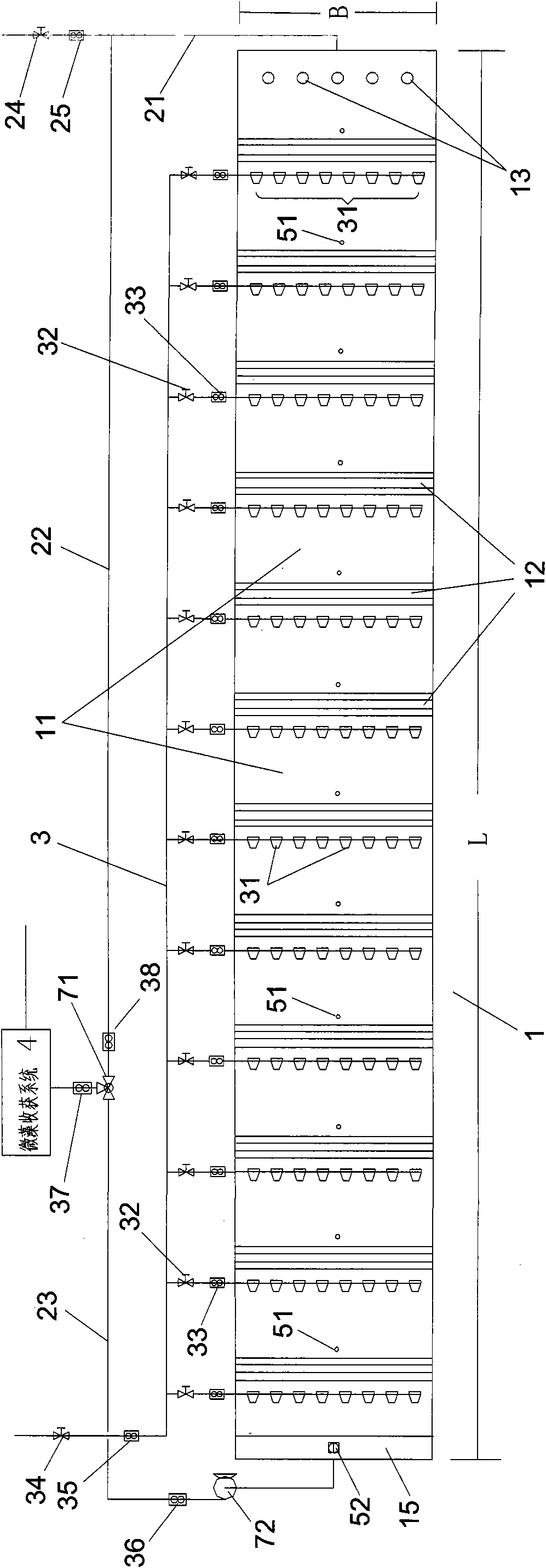

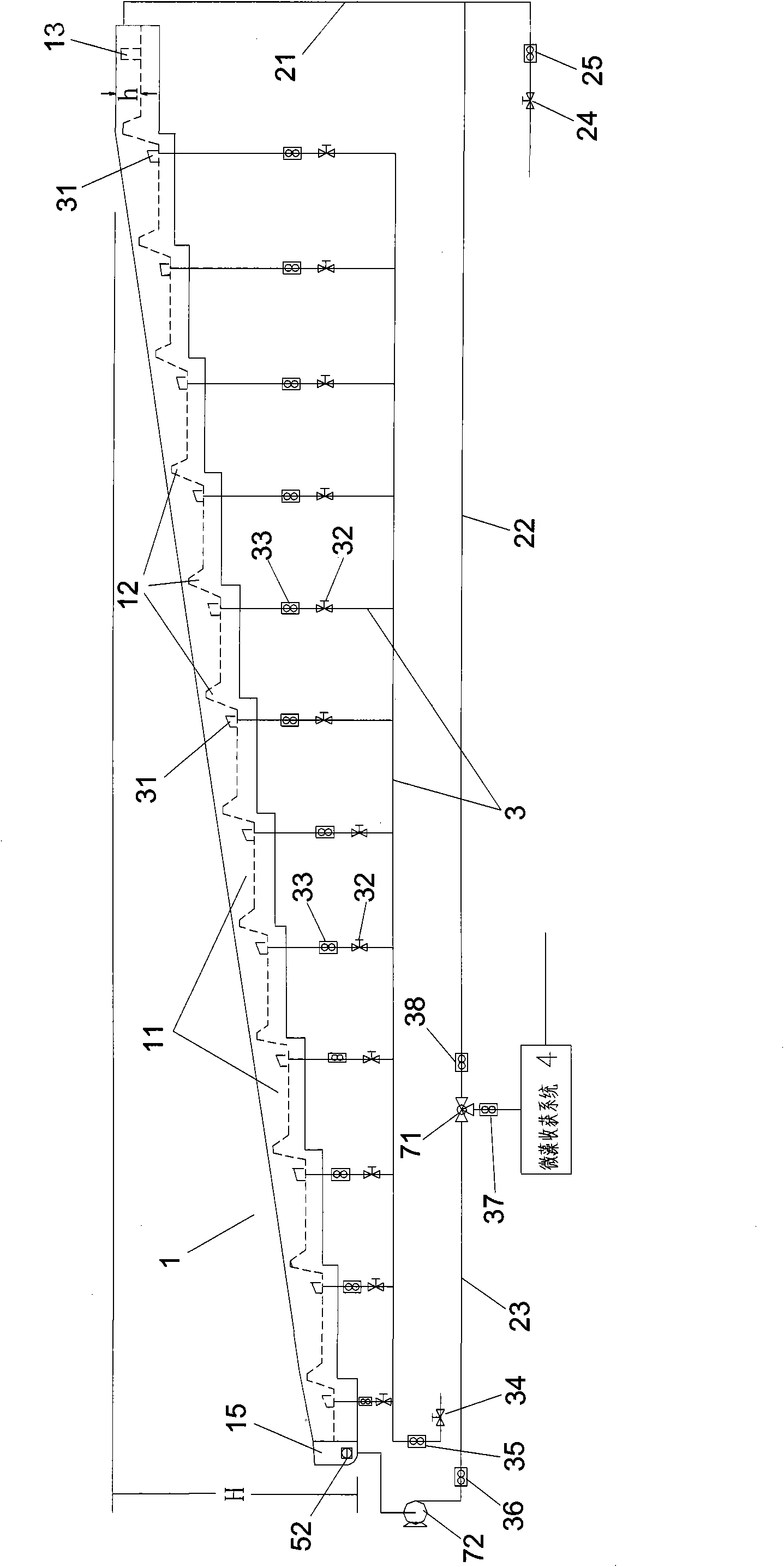

[0034] Such as figure 1 and figure 2 As shown, the reactor for microalgae outdoor cultivation of the present invention includes: a reactor unit 1 placed outdoors, an algae liquid delivery pipe, a carbon dioxide delivery pipe 3, a microalgae harvesting system 4, a delivery pump 72 and a flow control device Wait. Wherein, the algae liquid delivery pipe further includes a fresh algae liquid delivery pipe 21 , an algae liquid return pipe 22 and a connecting pipe 23 .

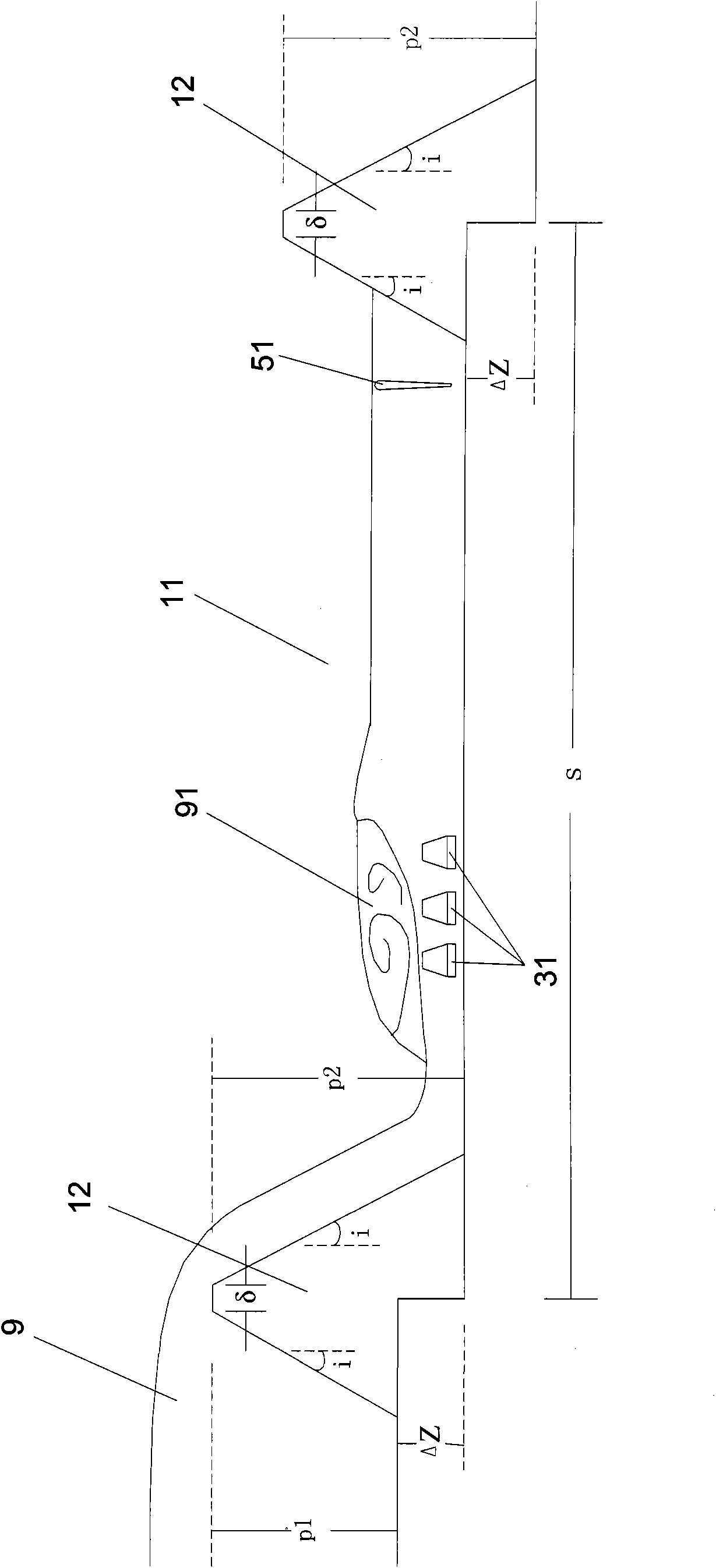

[0035] Such as figure 1 and figure 2 As shown, the reactor unit 1 has a stepped structure, and is connected by a plurality of water drop stilling units 11 that are lowered step by step from the upstream end to the downstream end. The upstream end of each water drop stilling unit 11 protrudes upward. The overflow weir 12 forms a recess for accommodating the algae liquid between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com