Fireproofing rectangular window

A rectangular window and fireproof glass technology, applied in the field of ship outfitting, can solve the problems of unsuitable fire protection requirements, inability to play a role in fire prevention, sound insulation, weather tightness, etc., and achieve the effect of beautiful appearance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

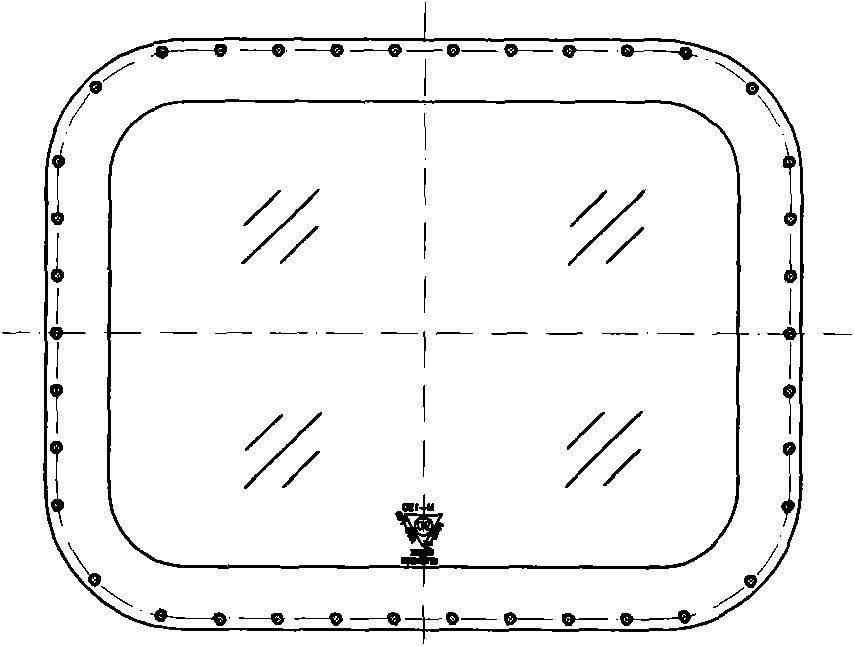

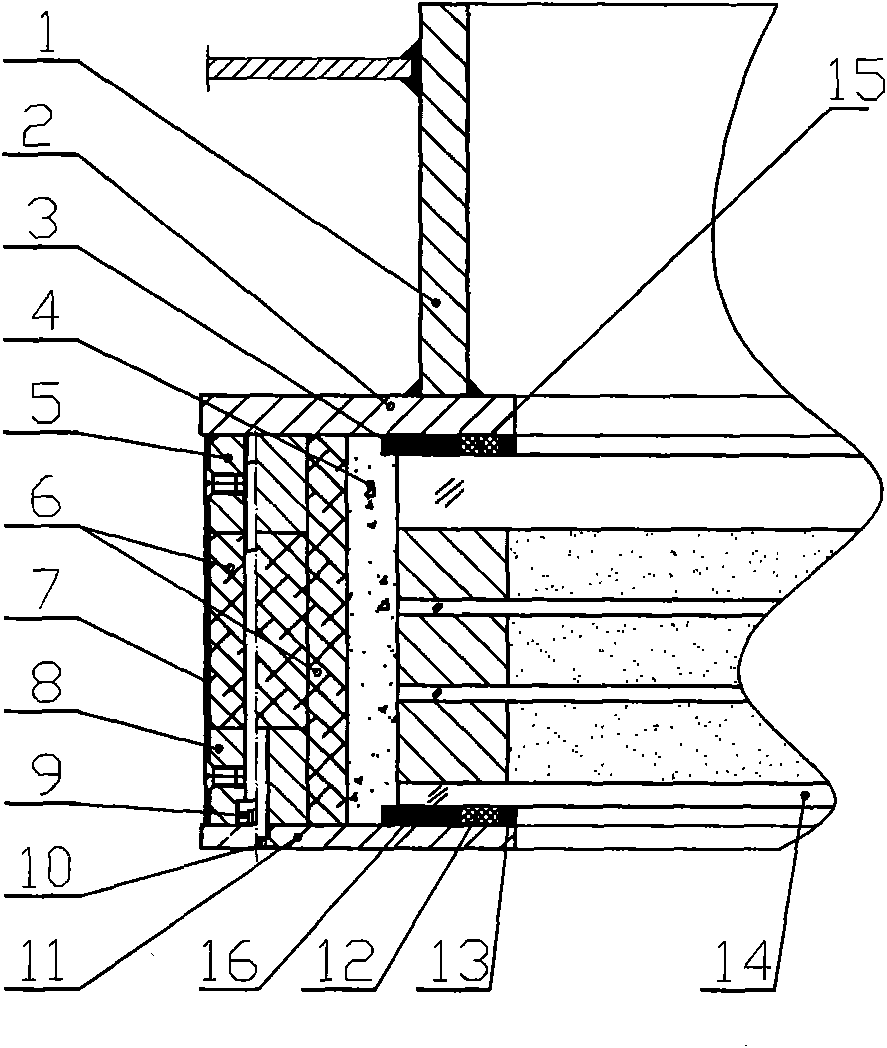

[0011] Such as Figure 1 ~ Figure 2 As shown, it includes enclosure 1, seat plate 2, first layer of fireproof expansion strip 3, ceramic wool 4, baffle plate 5, TC plate 6, decorative plate 7, window frame 8, hexagonal cylindrical head screw 9, and flat screw 10 , Press plate 11, second layer of watertight rubber strip 12, silica gel 13, fireproof glass 14, first layer of watertight rubber strip 15 and second layer of fireproof expansion strip 16, etc.

[0012] In the present invention, the coaming plate 1 is welded on the seat plate 2 earlier, and the baffle plate 5 is welded on the seat plate 2 . The window seat is composed of a hoarding plate 1, a seat plate 2 and a baffle plate 5. Then the TC board 6 and the window frame 8 are fixed on the baffle plate 5 with the socket head cap screw 9 . Paste the TC board 6 around the window frame, then paste ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com