Straight way type solar collector tube

A solar collector tube, straight-through technology, applied in the field of solar energy utilization, can solve different problems, achieve the effects of improving the utilization rate of thermal energy, efficiently utilizing the protection of the ecological environment, and not easy to form scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

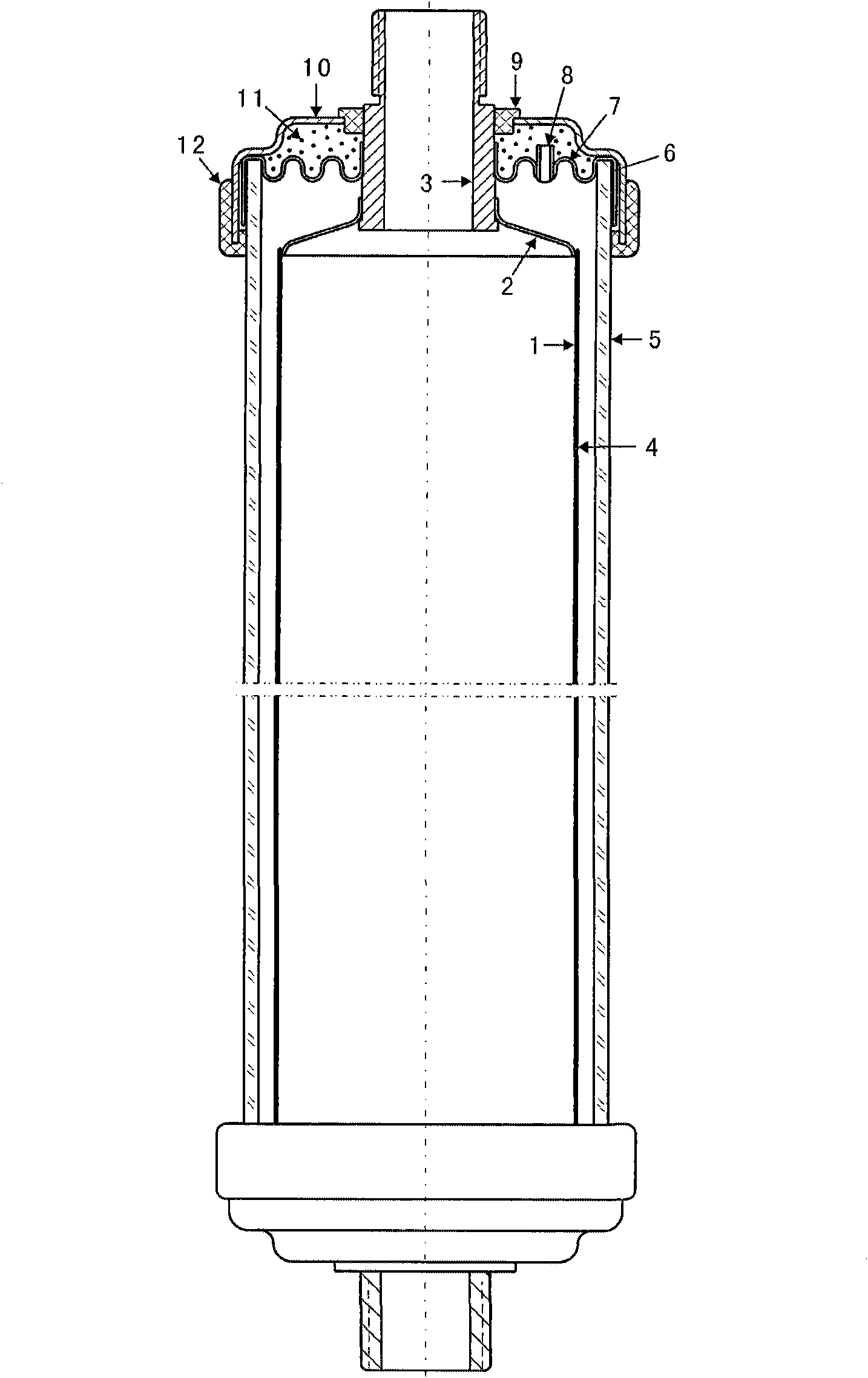

[0016] The present invention is described in detail below in conjunction with accompanying drawing: the present invention mainly is made up of inner metal tube assembly and outer glass tube; 3 is integrated by welding, and then a metal elastic piece 7 is welded or glued on the outer circle of the pipe joint 3, and there is an exhaust pipe 8 for air extraction on the metal elastic piece 7; the metal elastic piece 7 is a metal pull It is stretched or molded into a corrugated surface, and its rear end surface is formed into an S shape, and its inner hole is welded or bonded on the metal pipe connector 3 of the inner metal pipe assembly.

[0017] The outer surface of the hollow inner metal tube 1 is attached with a heat absorbing film layer 4 formed of a composite material including more than one metal element. The metal elastic member 7 is provided with a suction pipe 8 for vacuuming and which can be conveniently sealed.

[0018] The two exposed ends of the inner metal tube asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com