Self-lubricating integrated clamp wheel for sintering pallet

A self-lubricating and trolley technology, applied in the field of sintering machines, can solve problems such as the inability to ensure the accuracy of the chuck wheel, and achieve the effect of deleting the assembly process, reducing the installation workload and improving productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The embodiments given below in conjunction with the accompanying drawings further illustrate the specific implementation of the present invention.

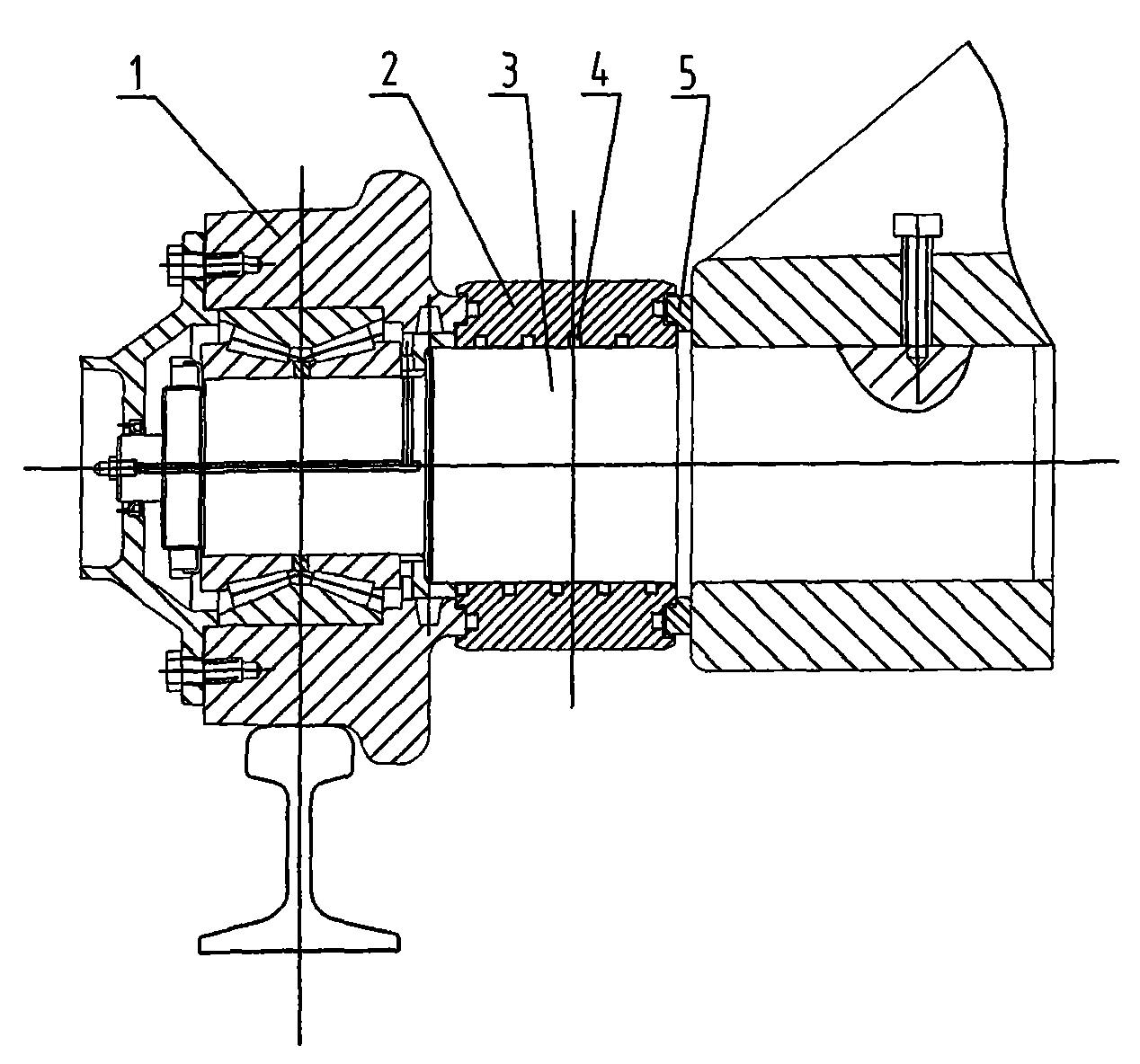

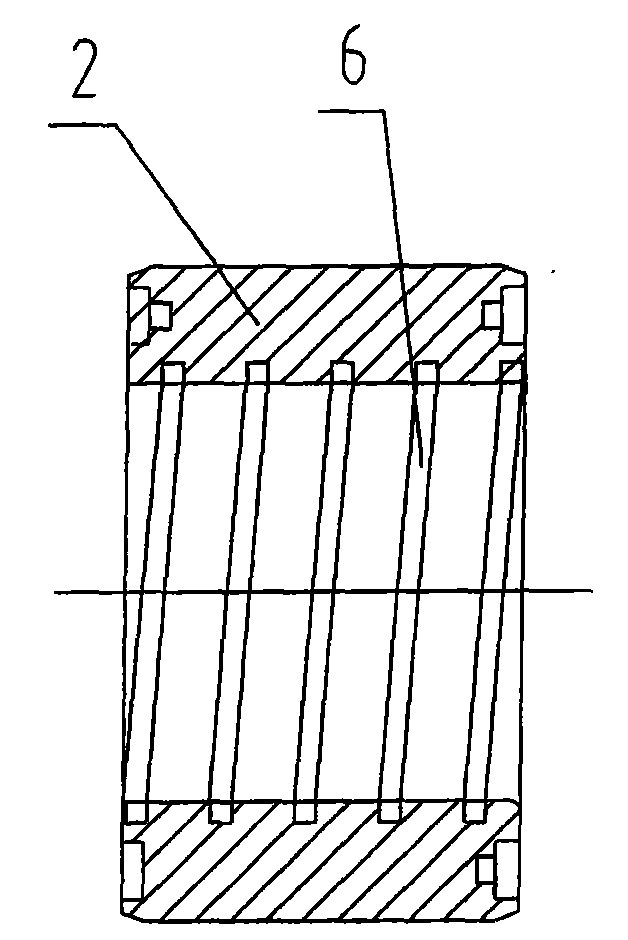

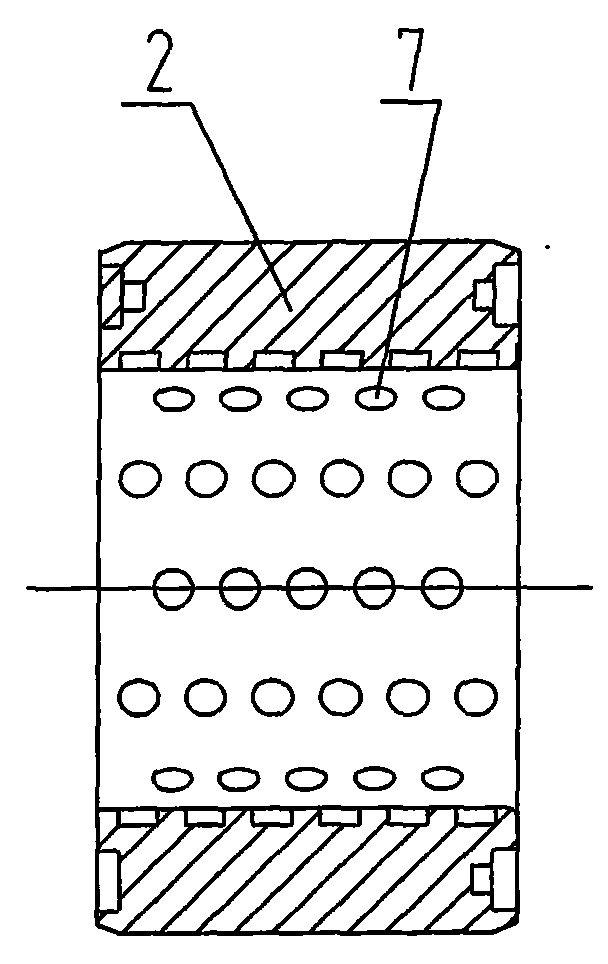

[0014] like figure 1 , figure 2 , image 3 , Figure 4 As shown, a self-lubricating integral card wheel for a sintering machine trolley of the present invention includes a spacer ring 5 and a card wheel 2 abutting against the spacer ring 5. It is characterized in that the card wheel 2 is a tubular card wheel 2. The inner hole wall of the tubular card wheel 2 and the tube walls at both ends are respectively provided with a solid lubricating cavity 4, the solid lubricating cavity 4 is inlaid with a solid lubricating material, and the inner hole of the tubular card wheel 2 is rotationally connected with the shaft 3 .

[0015] The solid lubricating cavity 4 is a spiral groove, a strip groove, or a round hole.

[0016] 1 among the figure is the sintering machine wheel.

[0017] After adopting the self-lubricating integral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com