Cooler

A cooler and cooling pipe technology, applied in the direction of heat exchanger types, indirect heat exchangers, fixed conduit components, etc., can solve the problems of large containers, long cooling time, waste of resources, etc., and achieve high-efficiency cooling effect and cooling capacity. Improved, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

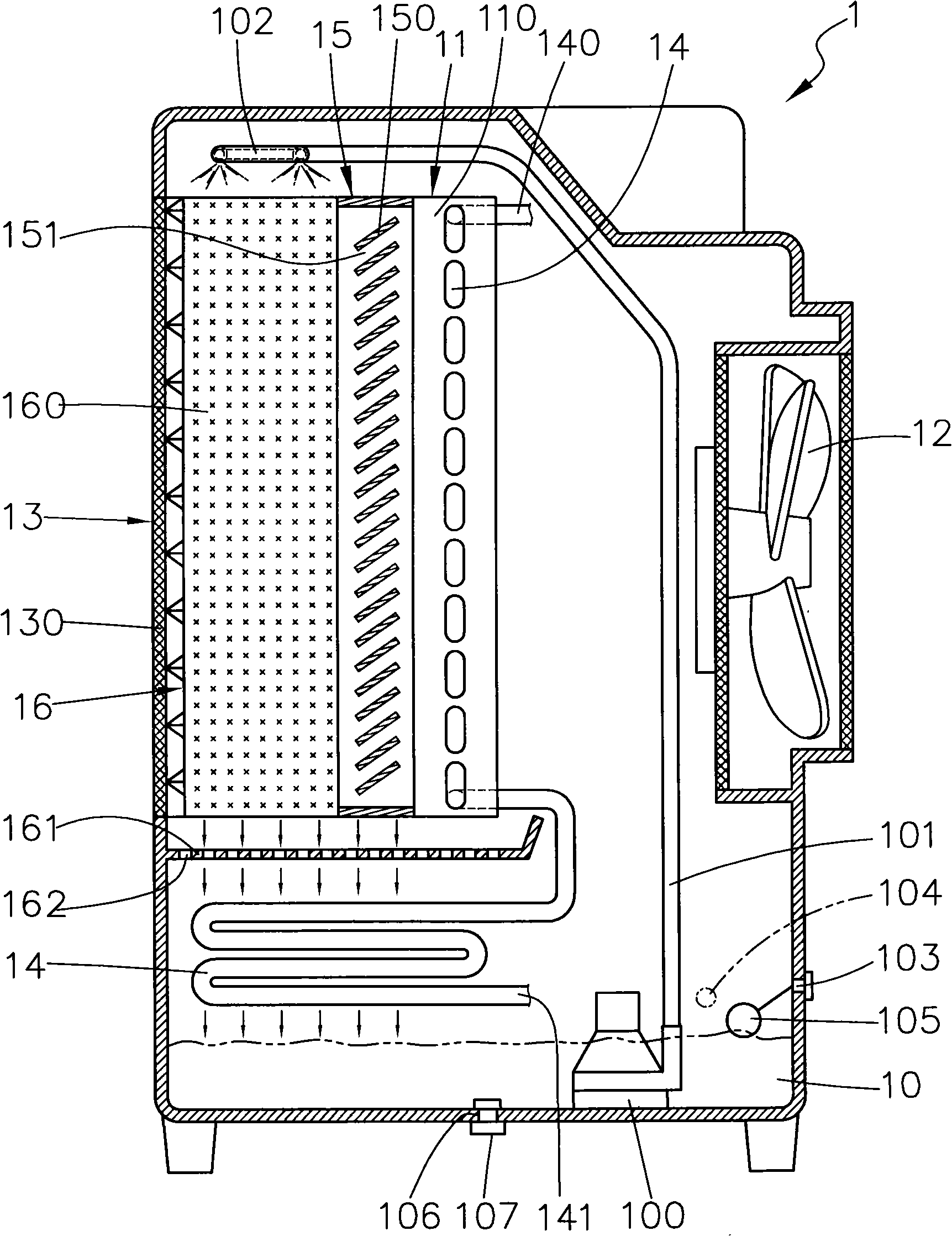

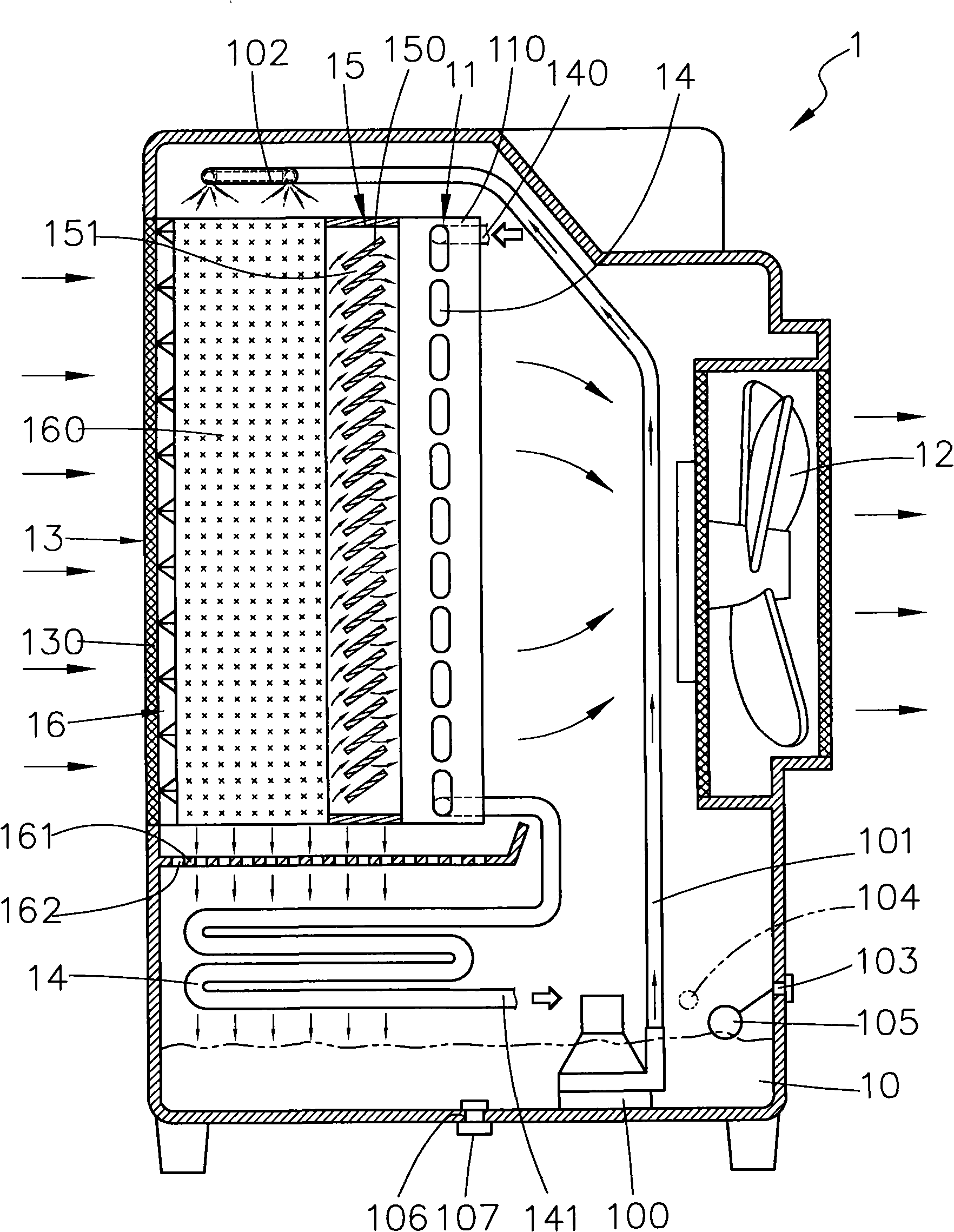

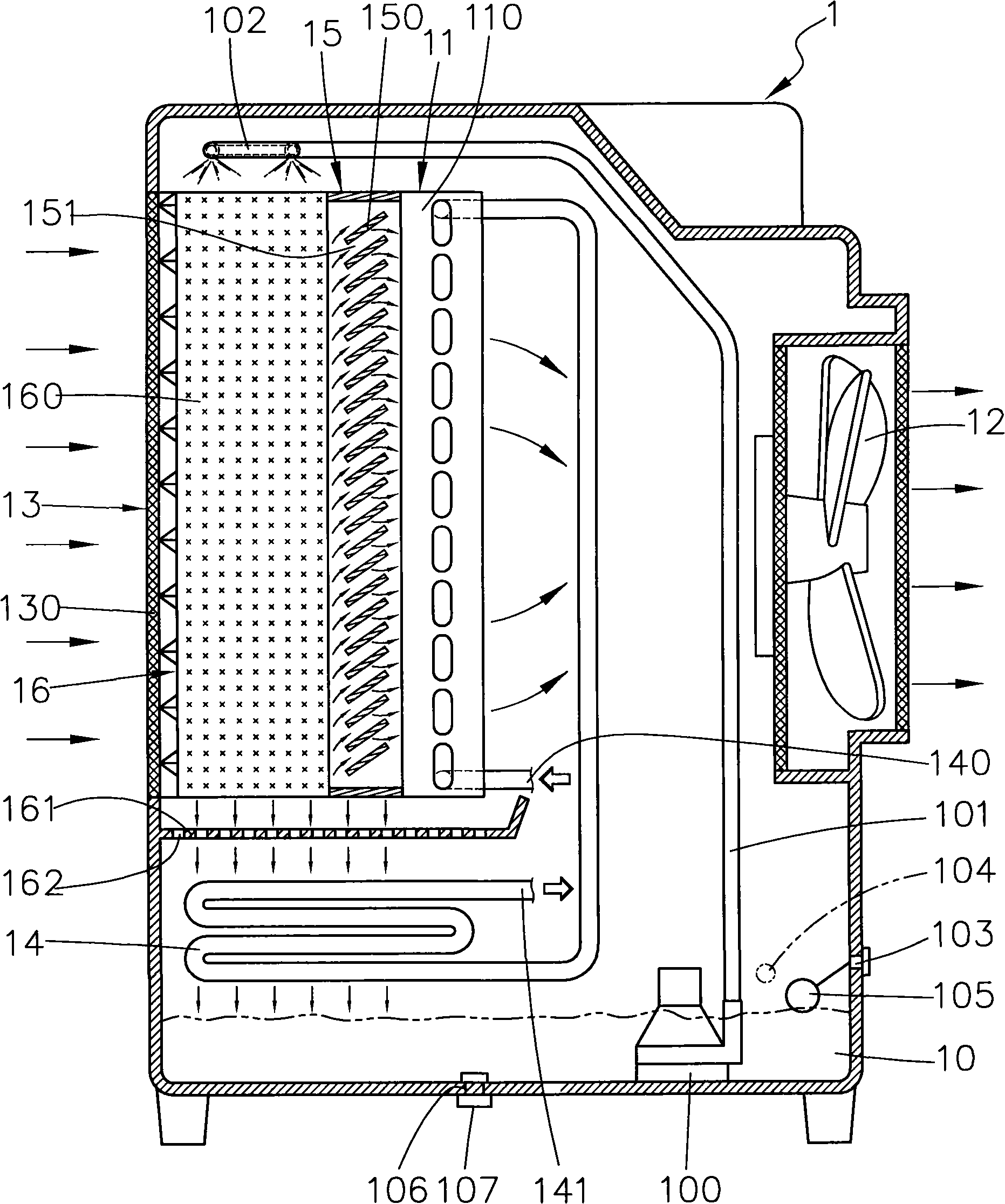

[0028] Relevant present invention is for reaching above-mentioned purpose of use and effect, the technical means that adopts, presents preferred feasible embodiment hereby, and cooperates as shown in the drawing, is described in detail as follows:

[0029] First, please refer to the figure 1 Shown, the present invention is provided with:

[0030] a body 1;

[0031] A water tank is located at the bottom of the body for containing cooling water. A water pump 100 is provided in the water tank 10. The water pump 100 is connected upward with a water pipe 101. The tail section of the water pipe 101 is set as a water spray pipe 102. In addition, a water injection port is provided on the side of the water tank 10. 103 and the overflow port 104, and a float 105 for controlling the water level is provided in the water tank 10, and a drainage hole 106 is provided at the bottom of the water tank 10, and is blocked by means of the plug sleeve 107;

[0032] At least one air-cooling heat d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com