Laser striping machine expansion cushion

A laser marking instrument and compensator technology, applied in instruments, measuring instruments, measuring devices, etc., can solve the problems of increased production costs, easy changes in indicators, flexible rotating parts, etc., to improve progress and efficiency, ensure measurement accuracy, Flexible and stable rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

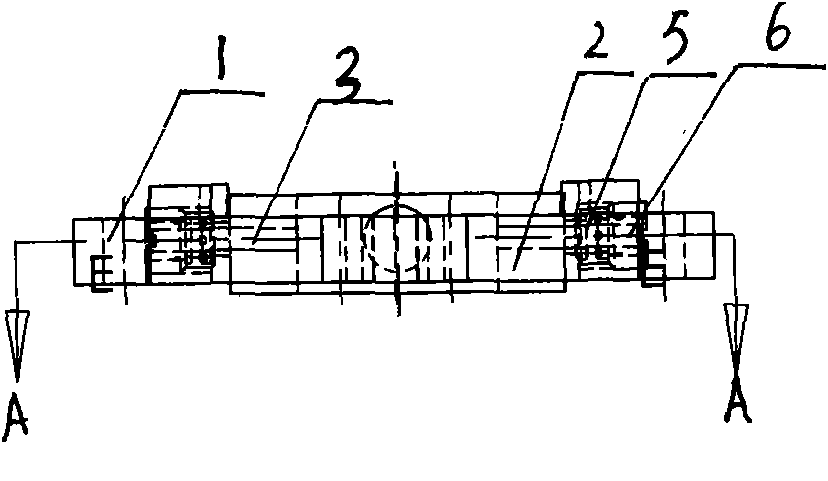

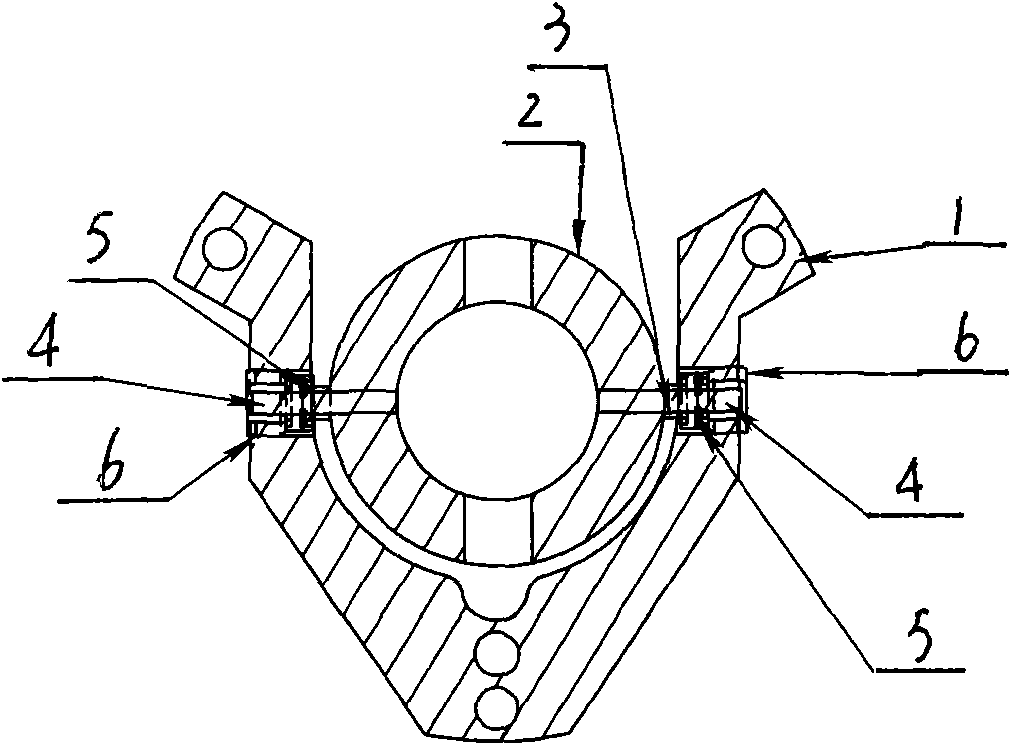

[0006] Such as figure 1 , figure 2 As shown, the outer ring 1 is U-shaped, and is installed on the base by a support rod, and the inner ring 2 is connected to the vertical rod for suspension; the outer ring 1 is connected to the same horizontal plane on both sides of the inner ring 2 through a rotating mechanism and is vertical. The rotating mechanism is a universal joint type, the rotating shaft 4 is set in the inner hole of the bearing 5 and is parallel to the axis center, the spacer ring 3 is connected to the rotating shaft 4 and one end withstands the inner ring inside the bearing 5, and the other end withstands the inner ring 2 , The hollow nut 6 withstands the outer ring on the outside of the bearing 5 . Rotating the hollow nut 6 can adjust the assembly gap, and can freely swing 360°, the rotation is flexible and stable, and the measurement accuracy is guaranteed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com