Capacitance electronic type fuel sensor

A capacitive sensing, electronic technology, applied in the liquid level indicator of physical variable measurement, etc., can solve the problems of excessive distribution parameters and difficult accurate measurement of capacitance parameters, and achieve the effect of easy manufacturing and reduced error

Active Publication Date: 2011-01-05

HARBIN VITI AUTOMOBILE ELECTRONICS

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

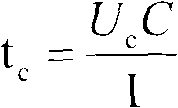

The purpose of the present invention is to provide a simple and easy-to-manufacture capacitive electronic fuel sensor, which solves the problems that the common distribution parameters in capacitive fuel sensors are too large and the capacitance parameters are difficult to measure accurately, and the capacitive electronic fuel sensor described in the present invention The capacitance measurement circuit and algorithm adopted by the sensor can effectively reduce the error of capacitance value measurement

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

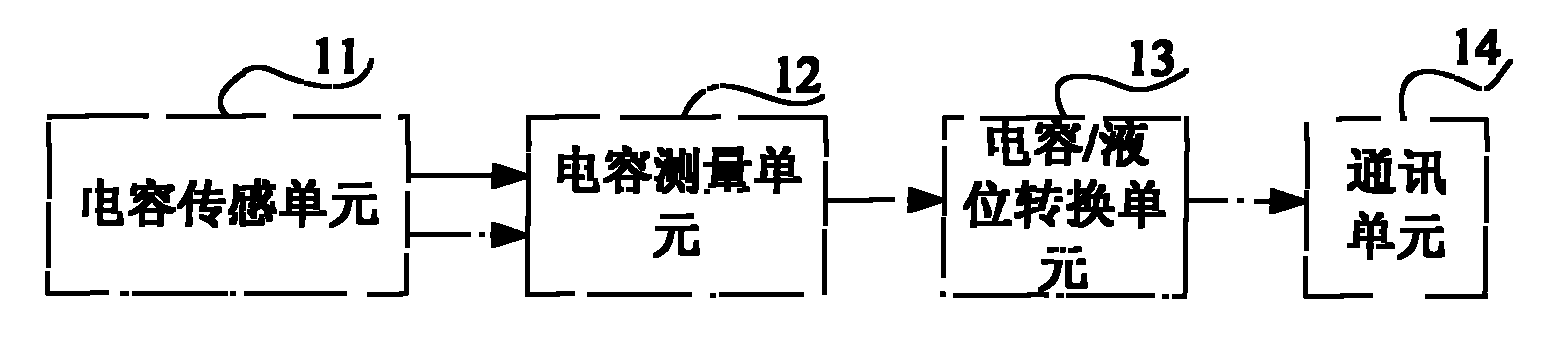

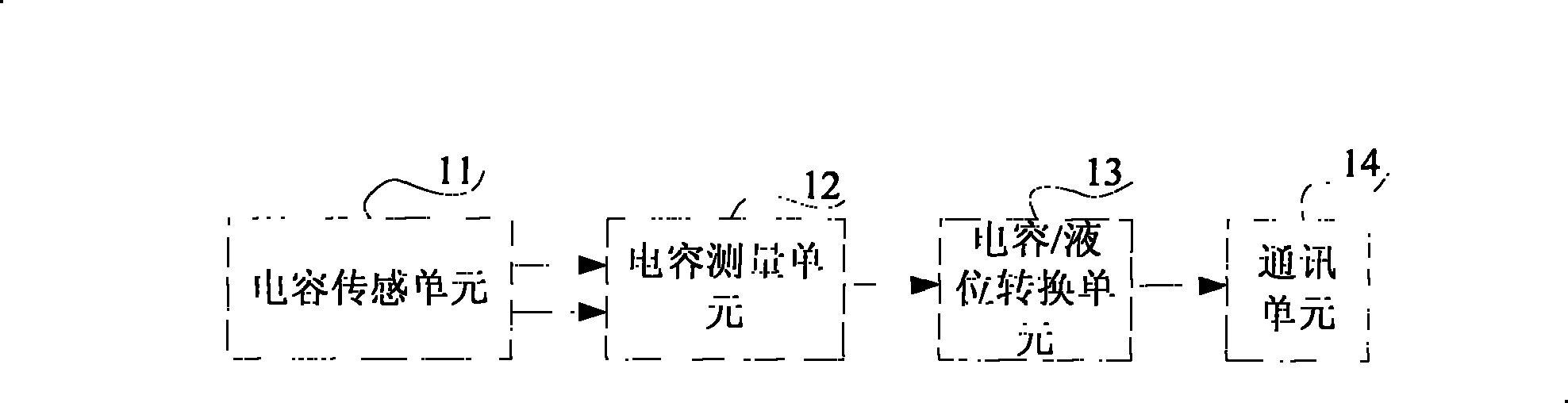

The invention discloses a capacitance electronic type fuel sensor, comprising a capacitance sensing unit, a capacitance measurement unit and a capacitance / liquid level conversion unit, wherein the capacitance sensing unit is a composite tubing capacitance element, comprising a metal external tube and a metal internal tube, and the metal external tube and the metal internal tube compose the a fuelliquid level sensor capacitor; the capacitance sensing unit is used for conversing fuel liquid level into a relevant capacitance value; the metal external tube and the metal internal tube of the capacitance sensing unit are respectively connected to an input terminal of the capacitance measurement unit by lead; the capacitance measurement unit is used for measuring a capacitance value of the capacitive sensor unit; and the capacitance / liquid level conversion unit is electrically connected to the capacitance measurement unit, for conversing the capacitance value form the capacitance measurementunit into liquid level. The sensor of the invention is simple and easy to manufacture, resolves common oversized distribution parameter in the capacitance fuel sensor and not-easy accurate measurement of the capacitance parameter.

Description

A capacitive electronic fuel sensor technical field The invention relates to a fuel sensor, in particular to a capacitive electronic fuel sensor. Background technique In the automotive fuel sensor market, fuel sensors mainly include reed rheostat fuel sensor, sliding rheostat fuel sensor, capacitive fuel sensor and pressure fuel sensor. The swing arm type and dry spring have the highest domestic market share. Tube fuel sensor. The capacitive fuel sensor has attracted widespread attention due to its advantages of high precision, good temperature characteristics, and ease of manufacture. Among the capacitive fuel sensors, variable medium capacitive sensors are the most widely used. At present, the main difficulties in the realization of its products are as follows: 1. It is easily affected by distribution parameters. Capacitive sensors are measured as capacitance values, so the product is easily affected by distribution parameters, resulting in measurement errors; 2. Cap...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01F23/26

Inventor 夏铁铮蒋于坤崔建民

Owner HARBIN VITI AUTOMOBILE ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com