Acquisition method of large scene based on line laser

An acquisition method, line laser technology, applied in the field of three-dimensional scanning, can solve the problems of prolonging the calibration time and errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

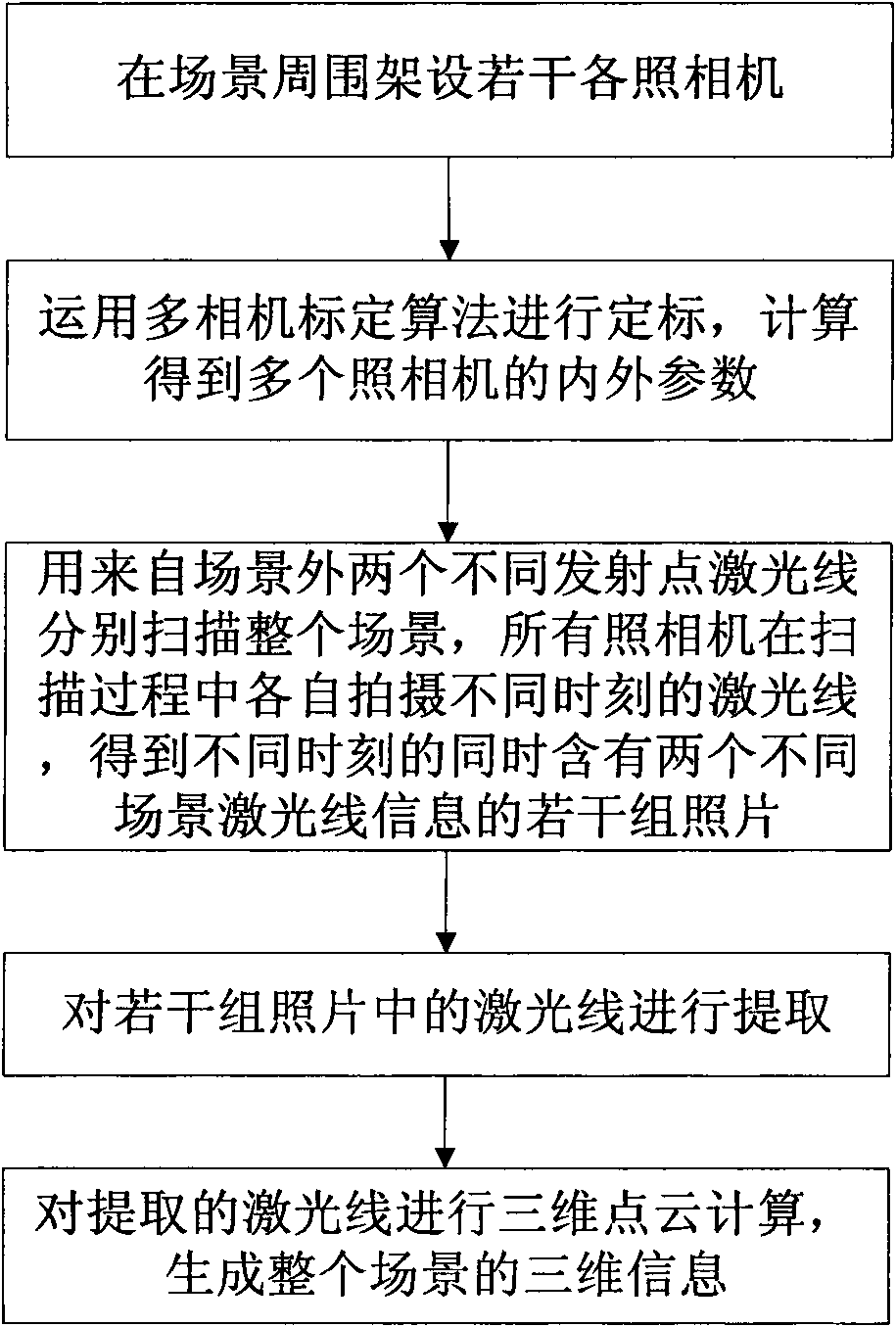

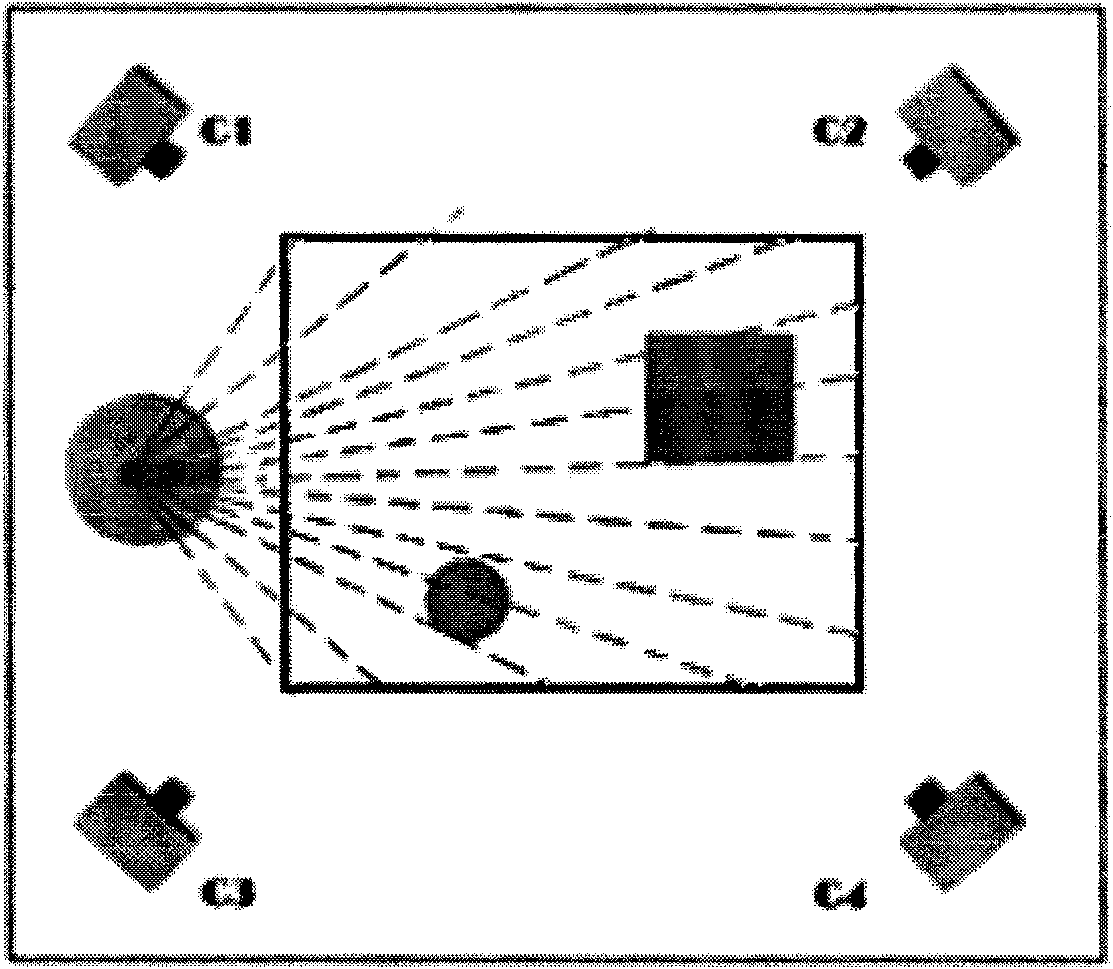

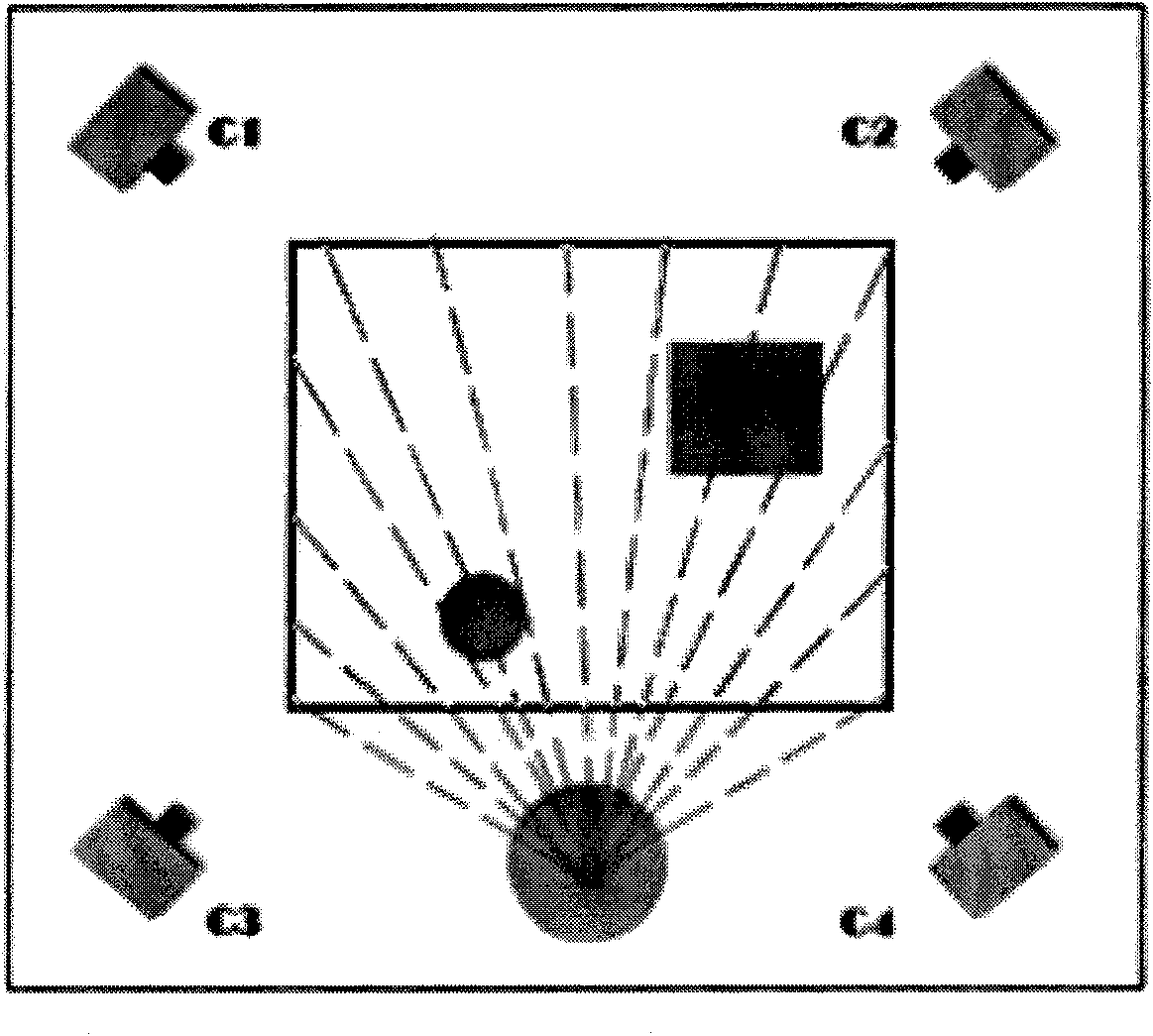

[0043] The present invention is a large-scale scene acquisition method based on line laser, such as figure 1 As shown, it includes the following steps: 1. Set up several cameras around the scene; 2. Use the multi-camera calibration algorithm proposed by Tomas Svoboda to perform multi-camera calibration, and calculate the internal and external parameters of multiple cameras in the scene; 3. Use the camera from the scene The laser line A of the outer emission point A scans the entire scene, and all cameras take pictures of the laser line A at different times during the scanning process, and obtain several photos respectively; 4. Change the laser line emission point and use the laser line from the outer emission point B of the scene B scans the entire scene, and all cameras take pictures of the laser line B at different times during the scanning process, and obtain several photos; for the same camera, take each photo obtained in step 3 and the photo corresponding to it in step 4 as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com