Separated power inductor based on a lead frame

A technology of lead frame and power inductance, which is applied in the direction of inductance with magnetic core, inductance/transformer/magnet manufacturing, transformer/inductor coil/winding/connection, etc. It can solve the problems of complex structure and inconvenient manufacturing, and achieve Small footprint, simple production, thin profile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will now be described in detail in conjunction with the accompanying drawings, which are used as examples of the present invention so that those skilled in the art can implement the present invention. It should be noted that the following figures and examples are not meant to limit the scope of the present invention. Some of the components of the present invention may be realized in part or in whole by known elements, and among these known elements, only those parts necessary for understanding the present invention will be set forth, and the detailed description of the remaining known elements will be are omitted so as not to obscure the content of the present invention. Additionally, the present invention encompasses, by way of illustration, present and future known equivalents to those referred to herein.

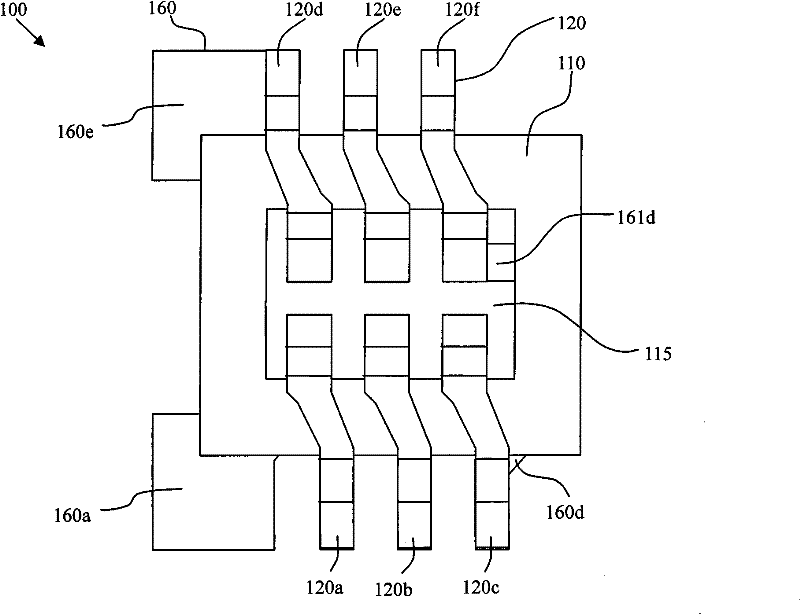

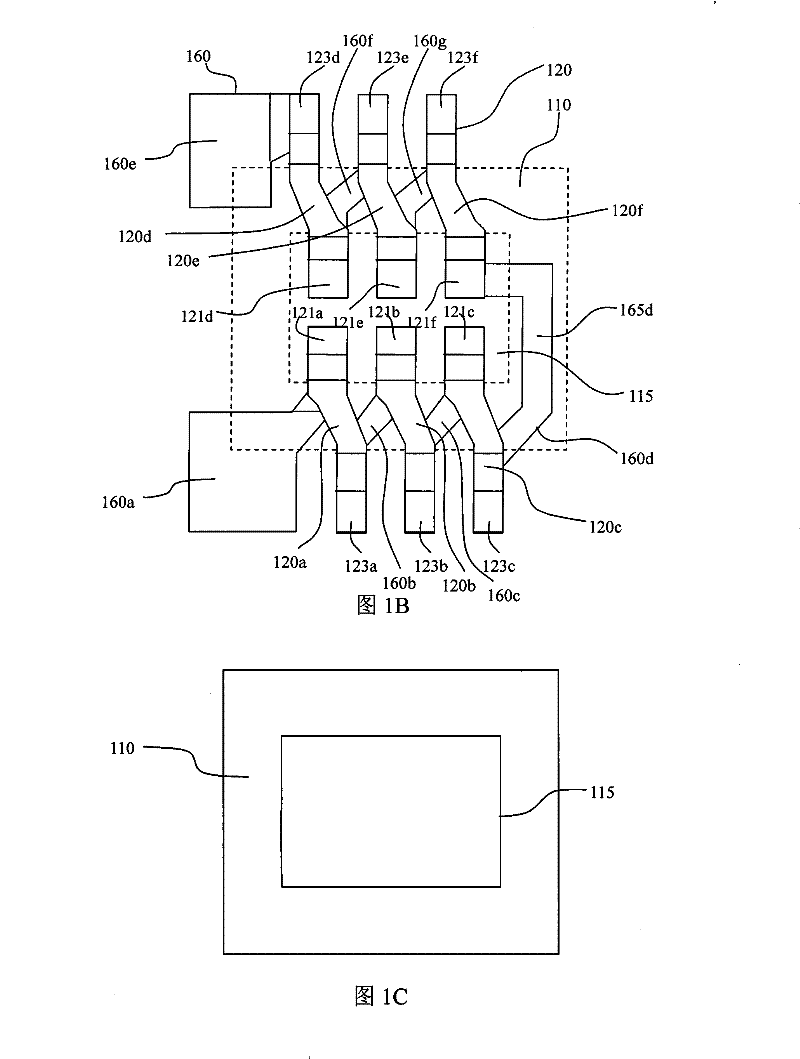

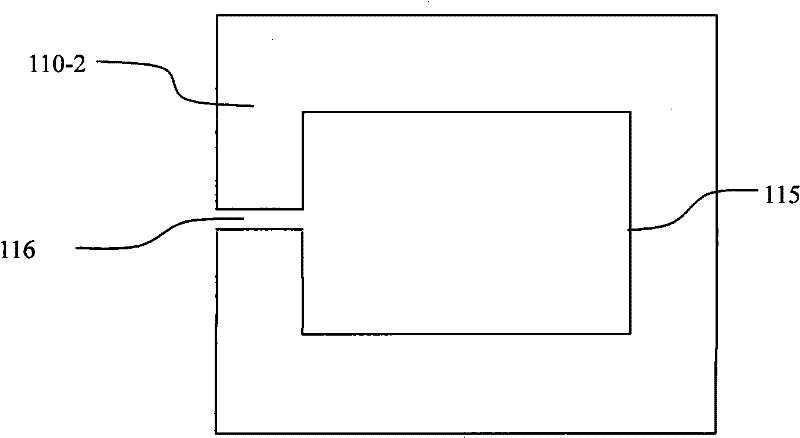

[0061] The invention provides a discrete power inductor based on a lead frame. Embodiments of the invention include a magnetic core having ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com