Transformer for improving the precision of output voltage

An output voltage and accuracy technology, applied in the field of new switching power supply transformers, can solve the problems of increasing the volume and loss of the transformer, large voltage errors, and complicated circuits, and achieves the effect of strong reliability and improved accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

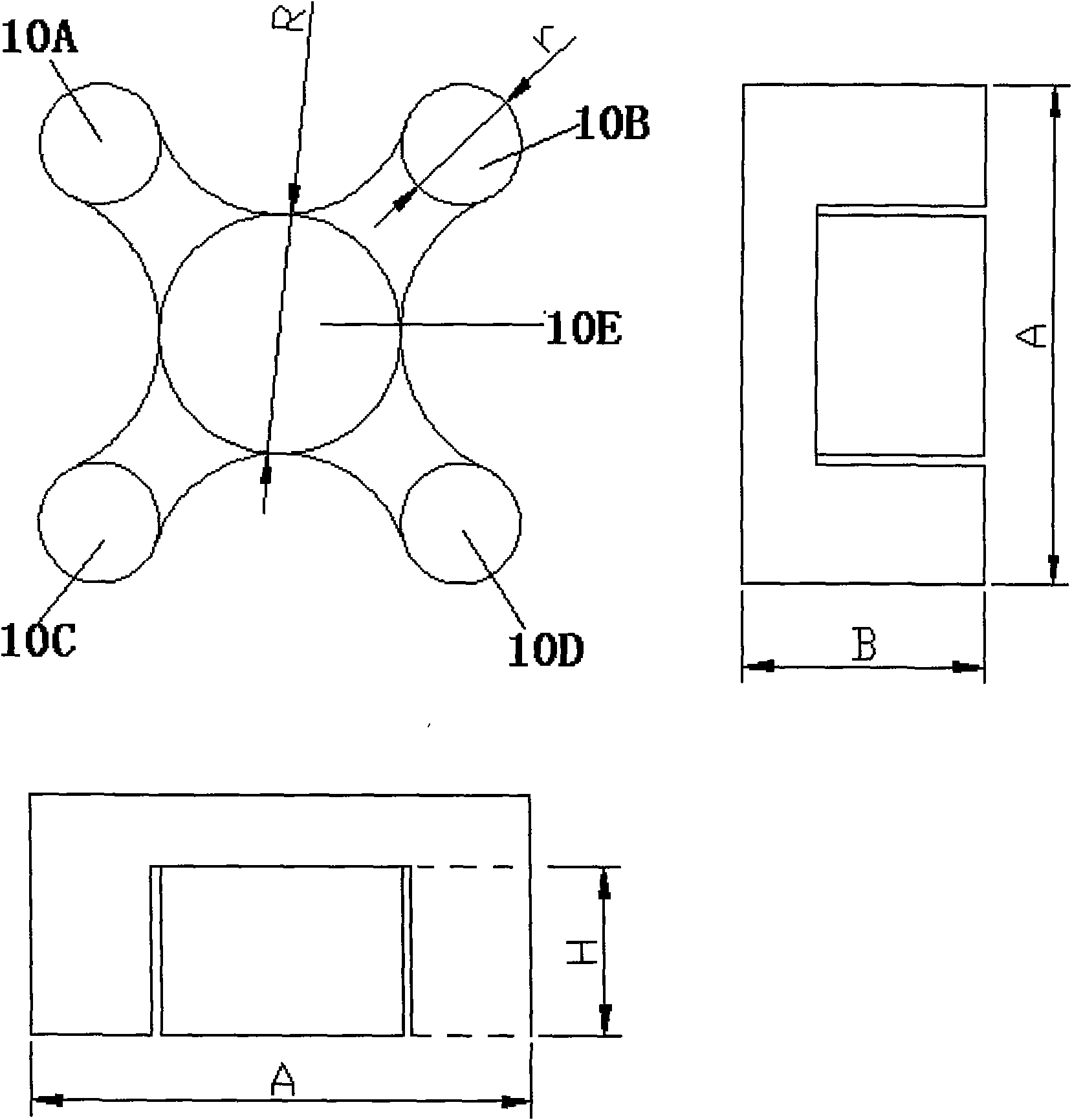

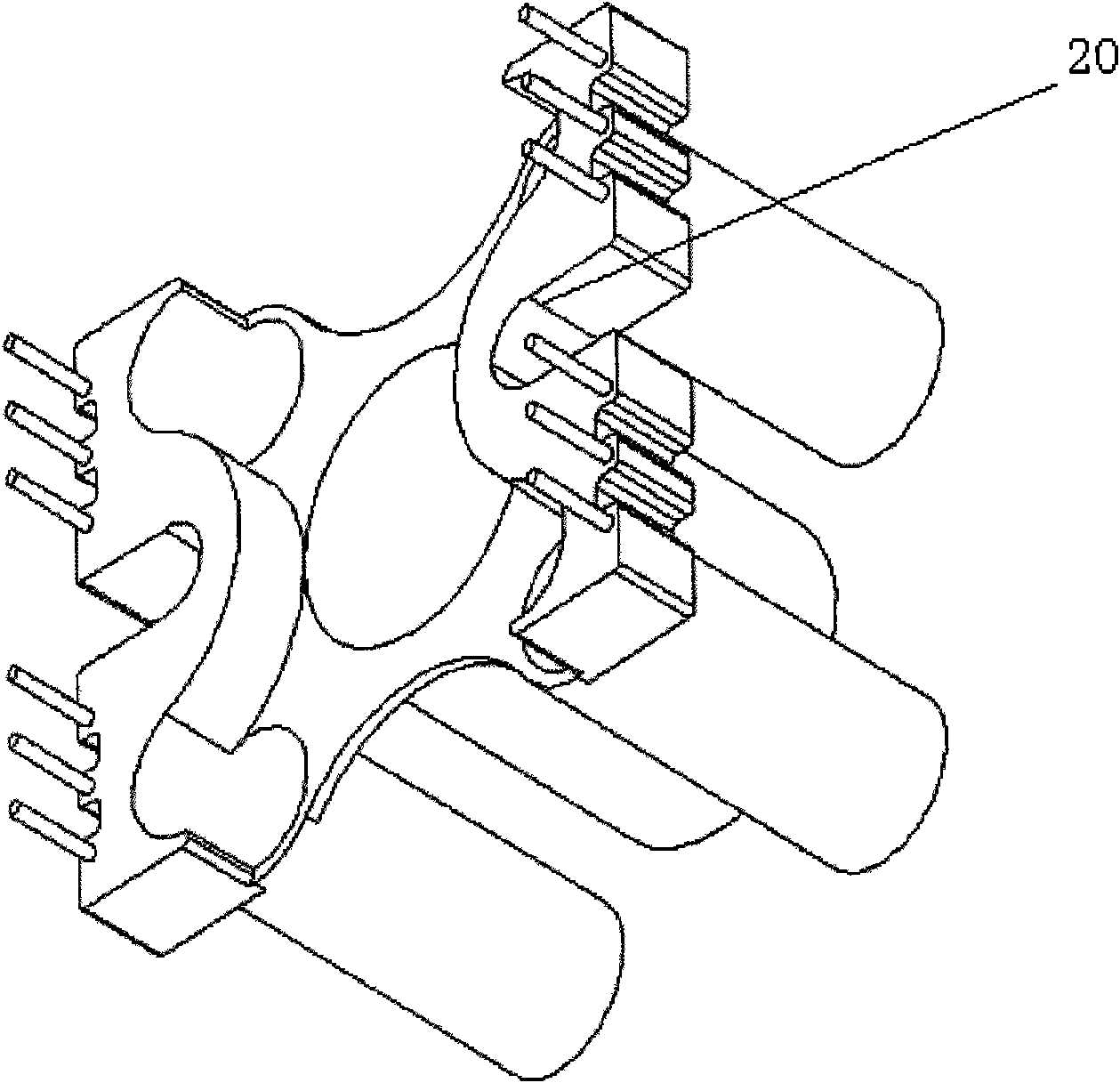

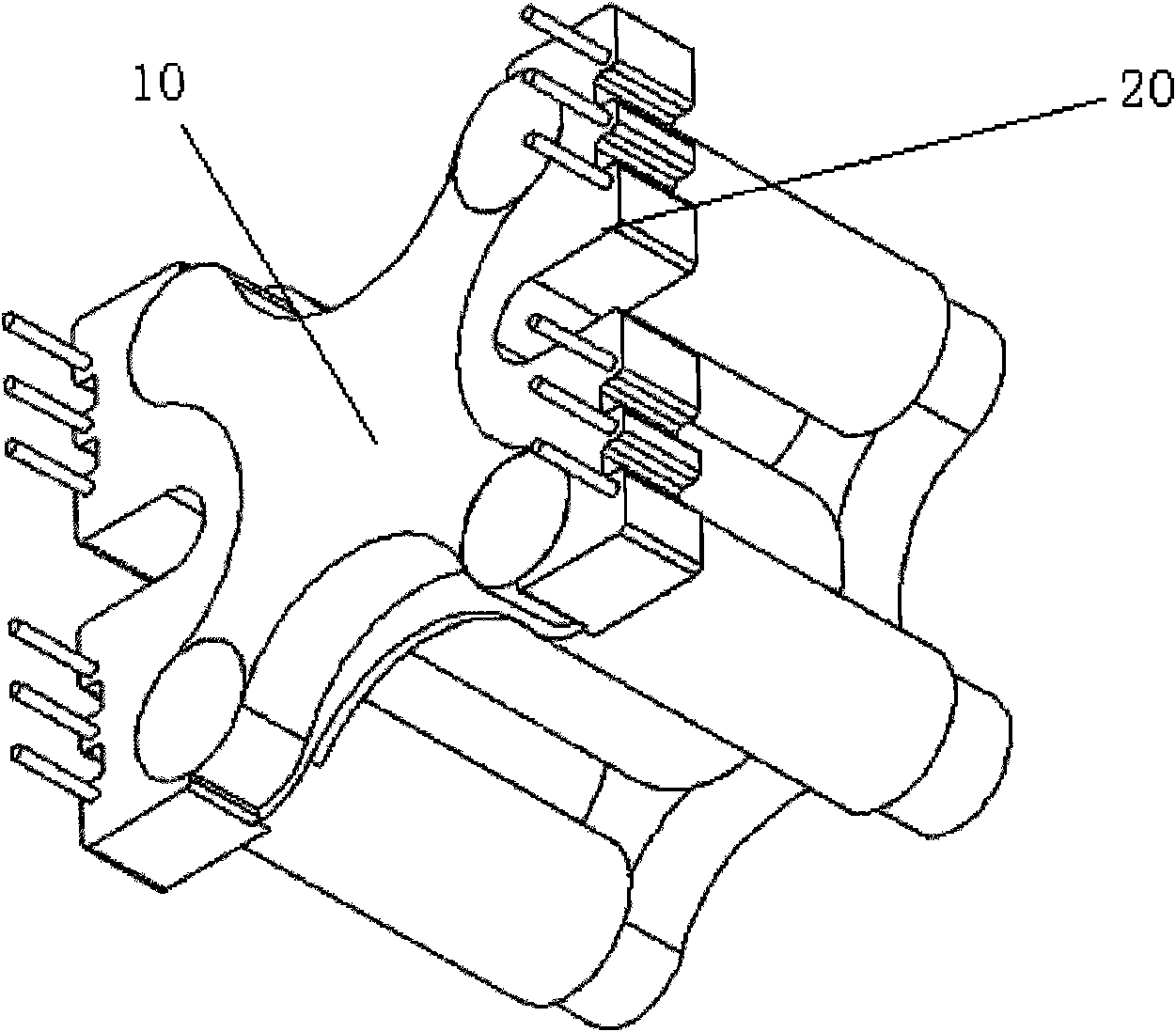

[0012] like figure 1 , figure 2 , image 3 As shown, a transformer that improves the accuracy of the output voltage includes a magnetic core 10 and a skeleton 20 matching the magnetic core. The magnetic core includes several side columns (not marked in the figure), a central column 10D, and the several Two side columns are respectively arranged around the central column 10D, the cross-sectional areas of the several side columns are respectively equal and the sum of the cross-sectional areas of the several side columns is equal to the cross-sectional area of the central column 10D, and each side column and the central column 10D The cross-sectional area of the connection part is equal to the cross-sectional area of each side column, the central column 10D is provided with a primary winding and a secondary integer multiple winding, and the several side columns are re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com