Screw extruder for continuous extrusion of materials with high viscosity

A screw extruder, high-viscosity technology, used in material forming presses, presses, manufacturing tools, etc., can solve problems such as impracticality and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

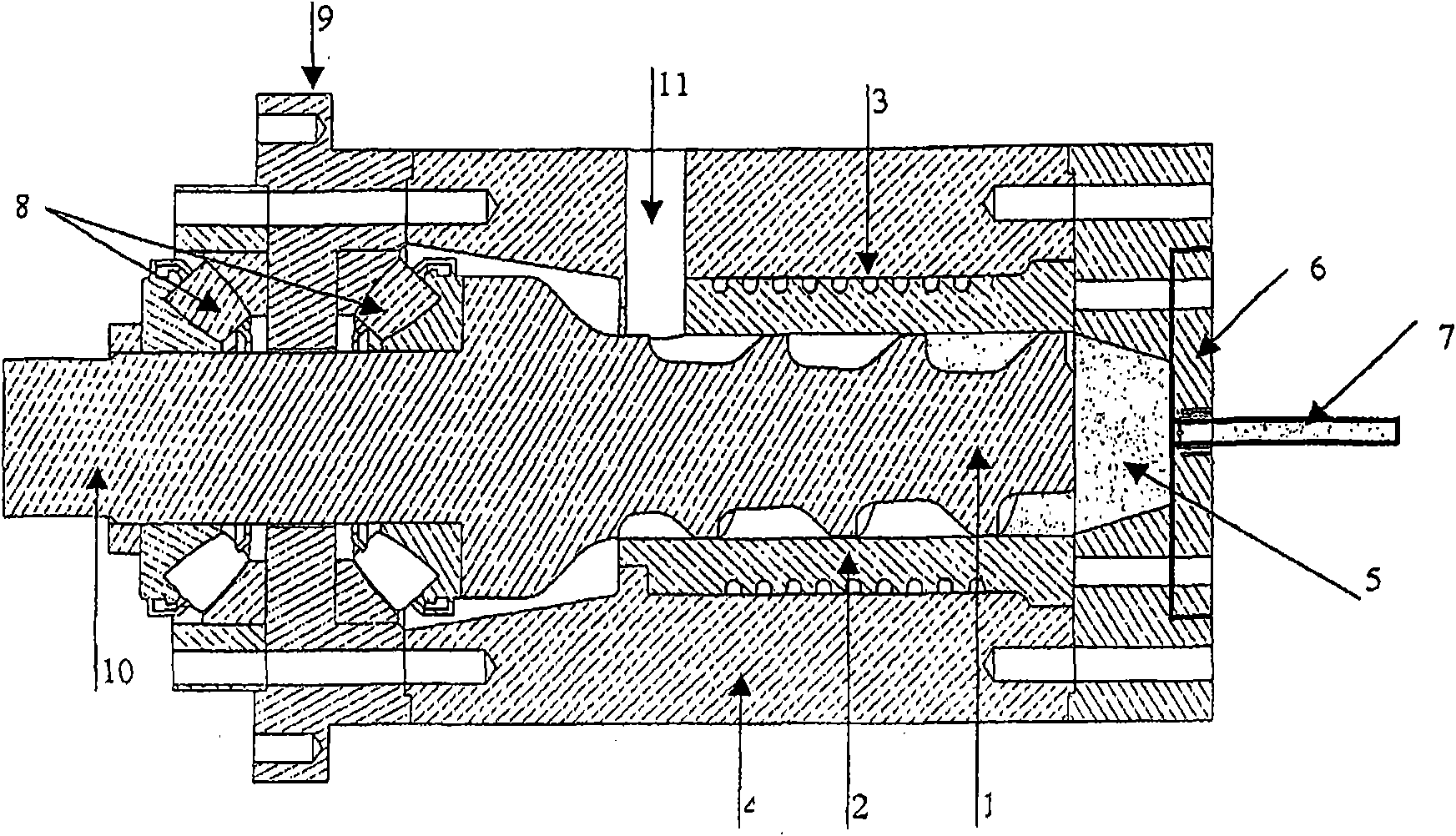

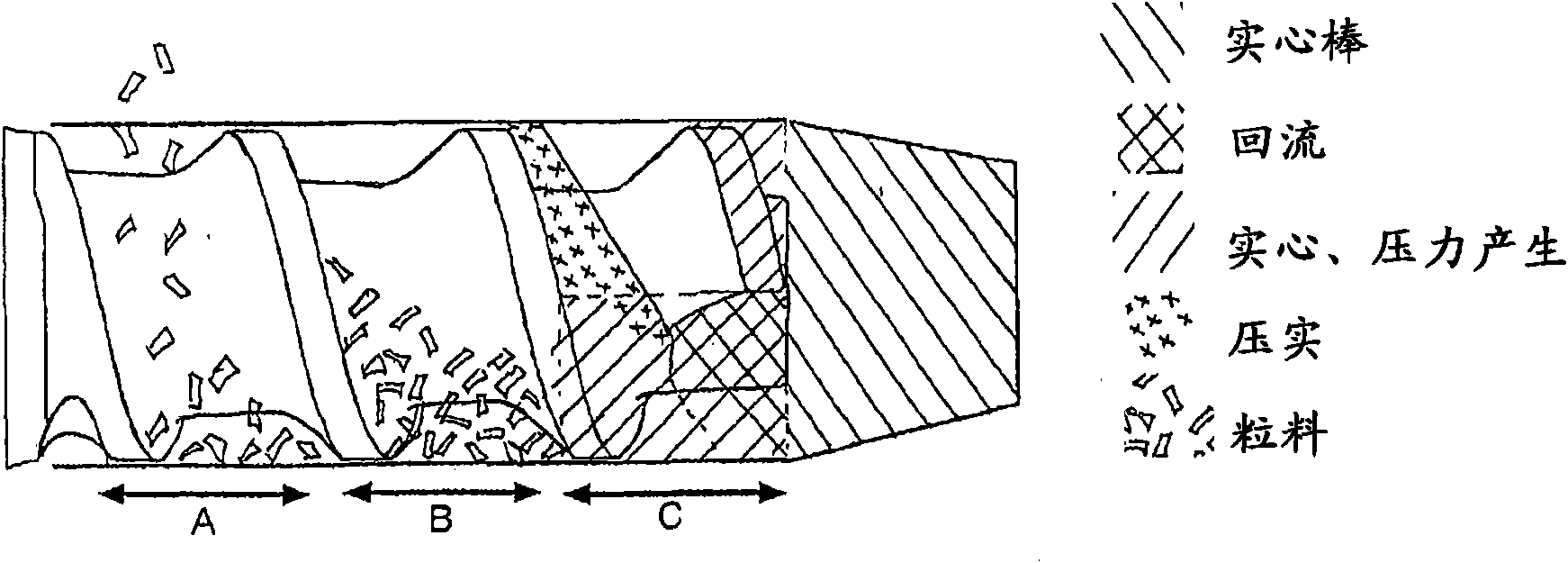

[0012] When extruding viscous and sticky materials such as metals in a continuous process with the aid of a screw extruder, the increased pressure due to the drag along the extruder of the material sticking to the liner and screw surfaces is achieved by forcing the material through the The pressure necessary for the mold at the end of the shell. Unlike typical screw extruders used in the polymer industry - where the viscosity of the polymer is much lower than that of the metal, the pressure area must be greatly reduced in order to avoid too high torque on the extruder. This object is achieved by combining a specially designed screw with extrusion chambers designed to restrict the rotational flow of metal. It is also necessary to control the temperature profile along the extruder. The overall length of the screw is thus also significantly shorter, which is typically 1.5-2.5 times the screw diameter.

[0013] The extruder is preferably fed granular metal at T < Ts, where Ts is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com