Robot device, treatment device with the robot device, ashing device, and ashing method

A technology of robotics and ashing, applied in the direction of manipulators, conveyor objects, transportation and packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] Embodiments of the present invention will now be described with reference to the drawings.

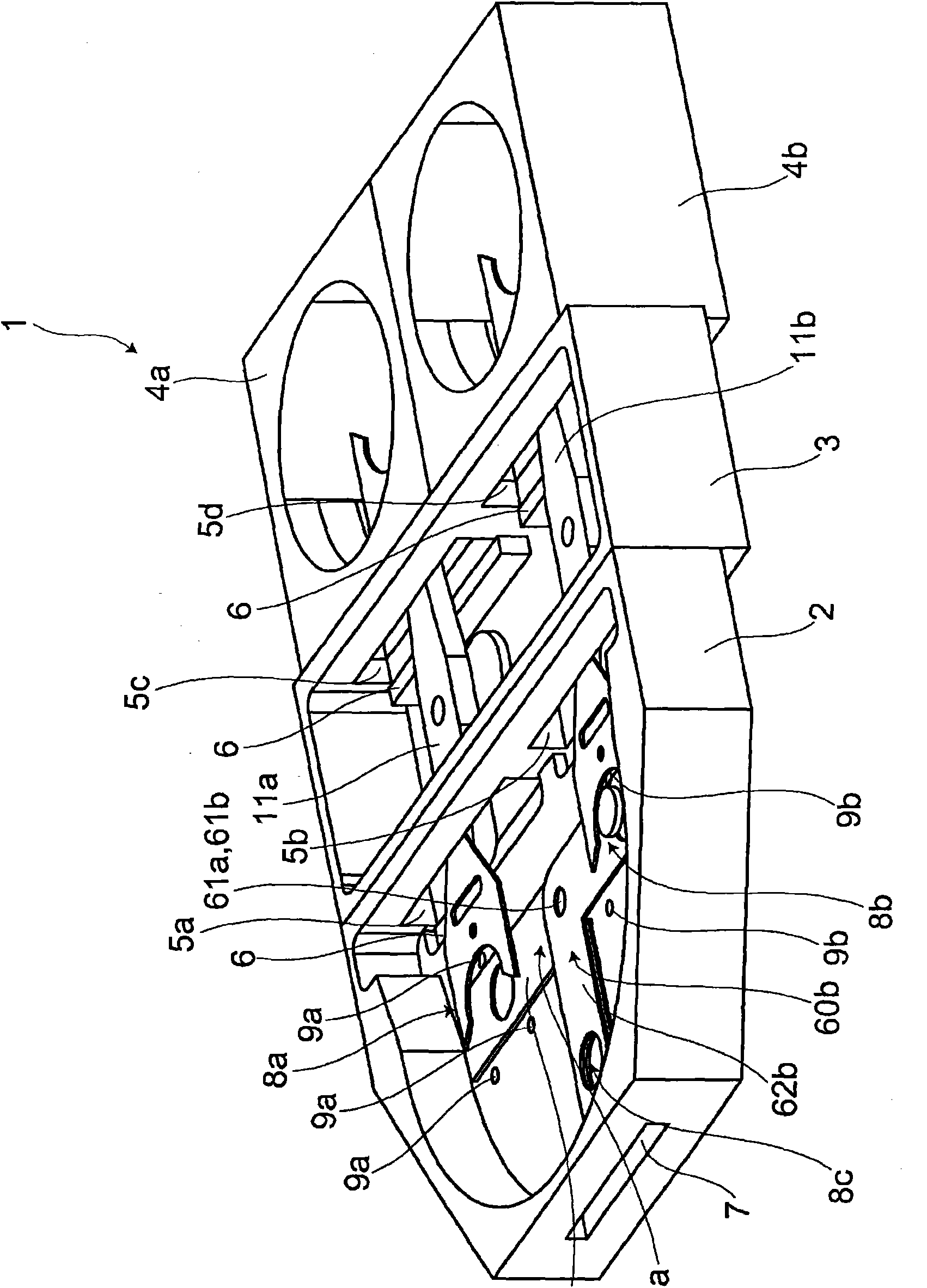

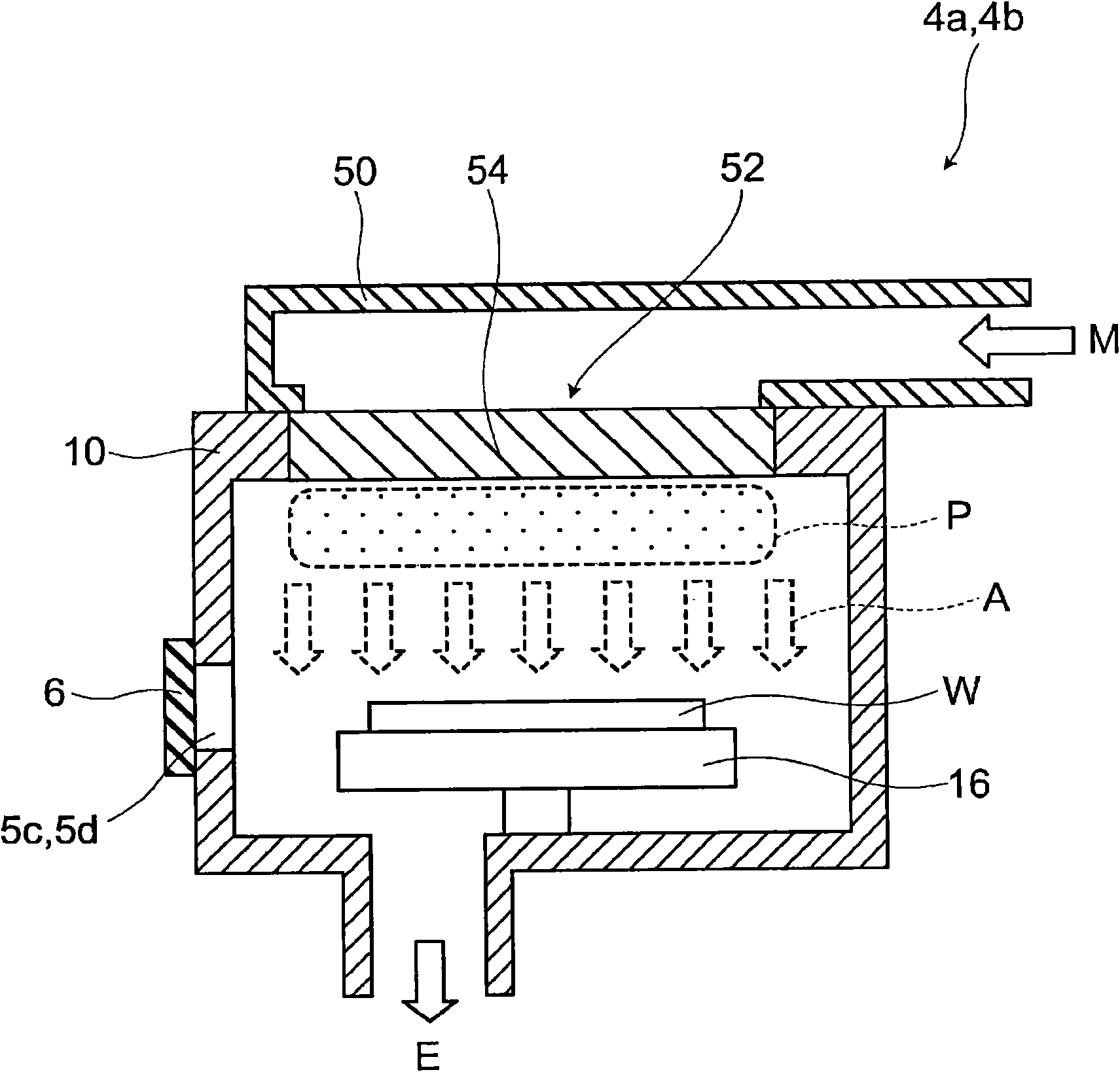

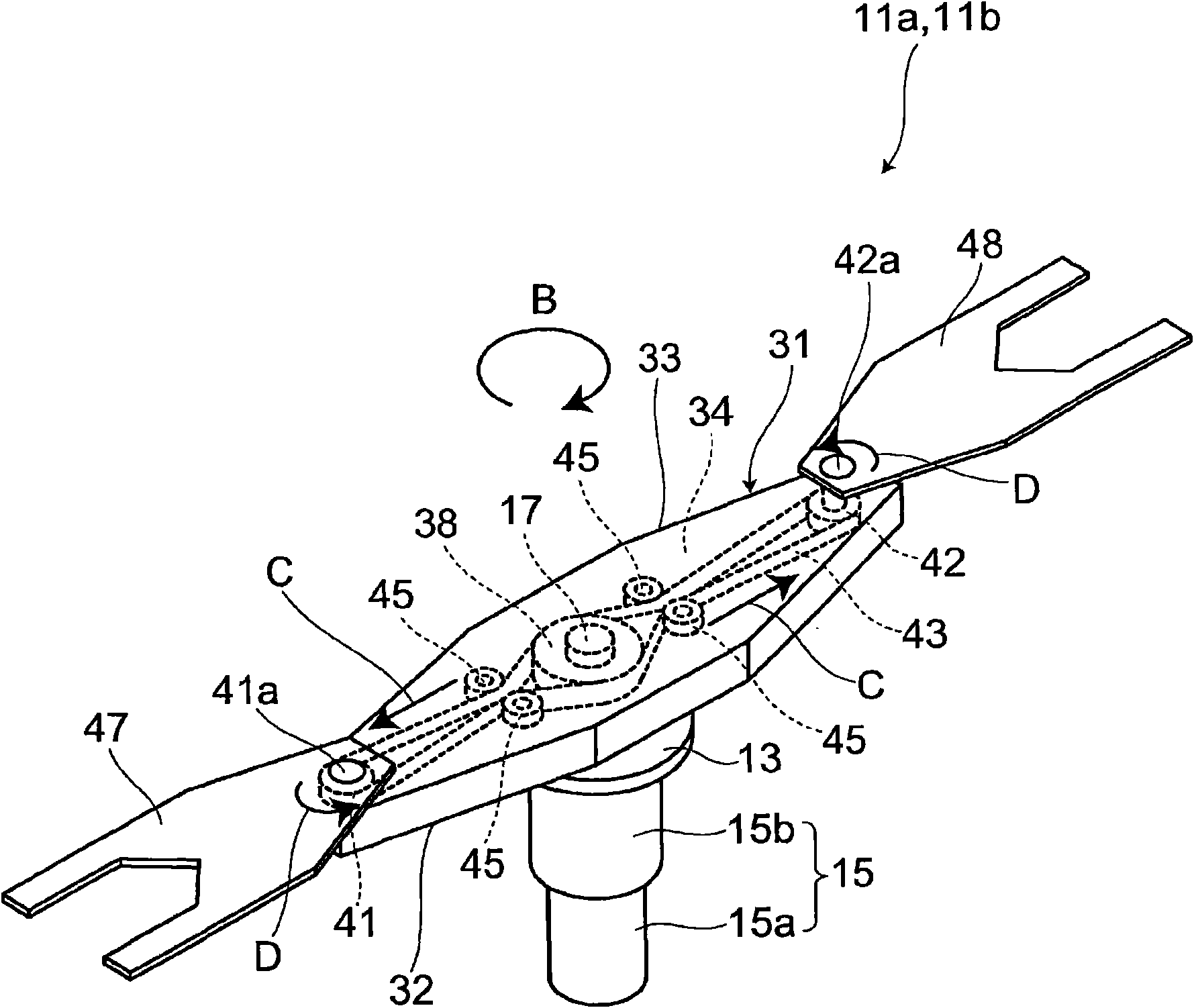

[0071] figure 1is a schematic cutaway perspective view showing a processing device according to an embodiment of the present invention. Such as figure 1 As shown, the processing apparatus 1 comprises a load lock chamber 2 adapted to reduce the pressure therein, a transfer chamber 3 and processing chambers 4a, 4b. multiple (in figure 1 Handover gates (handover gates) 5a to 5d at four locations in total in the view of , are formed in parallel in the walls between the load lock chamber 2 and the transfer chamber 3 and between the transfer chamber 3 and the processing chambers 4a, 4b. The load lock chamber 2 and the transfer chamber 3, and the transfer chamber 3 and the processing chambers 4a, 4b are connected by transfer gates 5a to 5d, allowing the internal spaces of the respective chambers to communicate with each other. Here, the tops of the load lock chamber 2, the transfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com