High-entropy alloy solder used for welding copper and aluminum and preparation method thereof

A technology of high-entropy alloys and solders, applied in welding equipment, welding/cutting media/materials, welding media, etc., to achieve the effects of easy processing and assembly, good corrosion resistance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

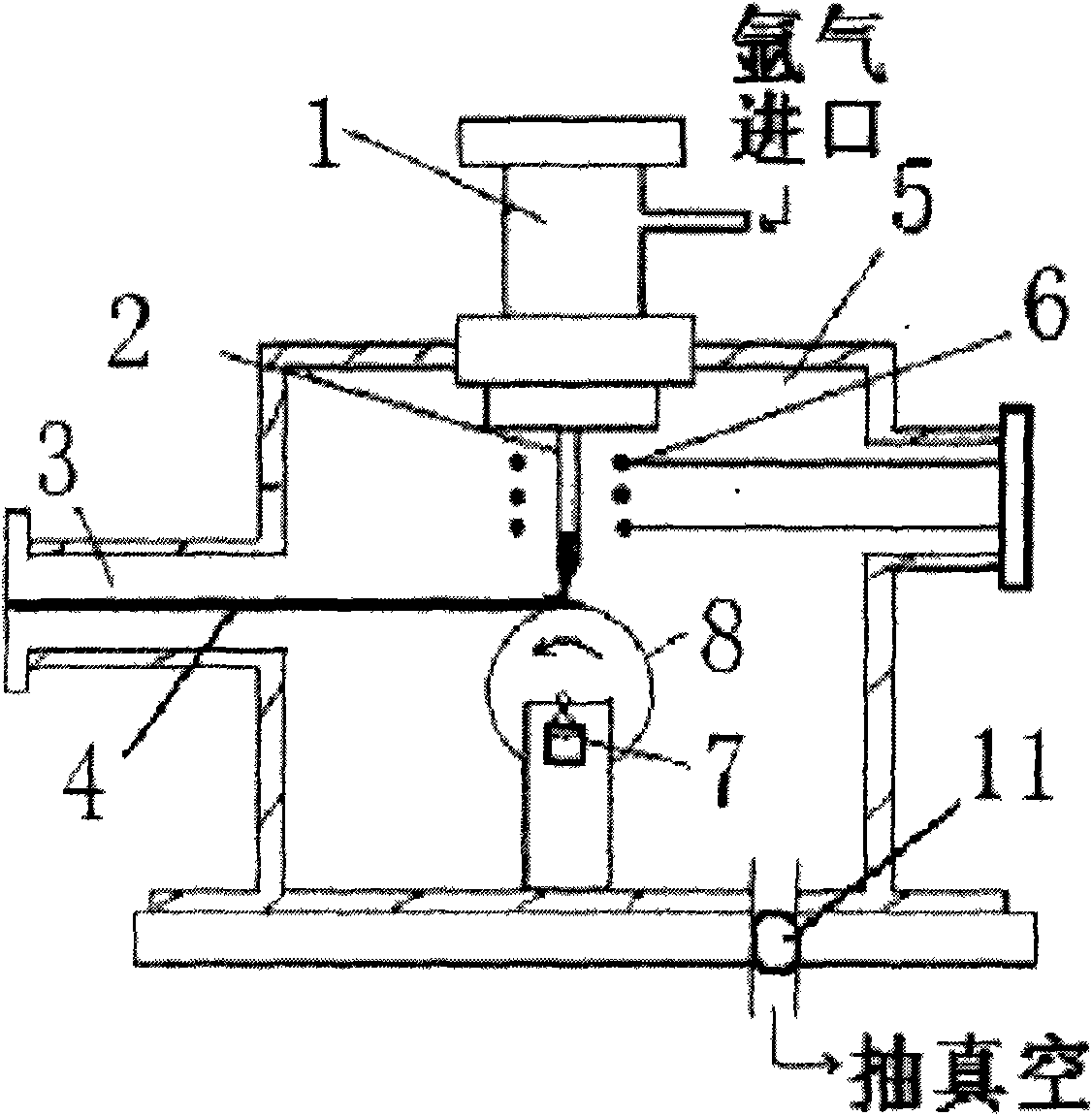

[0022] The preparation method of the high-entropy alloy solder of the present invention uses a single-roller rapid solidification device to prepare, and the device structure is as follows figure 1 As shown, a copper roller 8 driven by a single-phase asynchronous motor 7 is provided in the vacuum chamber 5, a high-frequency induction coil 6 is arranged directly above the roller 8, and a high-frequency induction coil 6 is provided in the high-frequency induction coil 6 A cylindrical quartz crucible 2, the lower end of the crucible 2 is provided with a 0.3 ± 0.05mm wide slit nozzle parallel to the roller 8, the vacuum chamber 5 is provided with a vacuum pump 11 to communicate with the outside; on the top plate of the vacuum chamber 5 is provided with Small vacuum chamber 1, the small vacuum chamber 1 has an Ar gas inlet, the bottom of the small vacuum chamber 1 communicates with the upper opening of the crucible 2, and a collection chamber 3 is arranged on the side of the vacuum ...

Embodiment 1

[0033] Embodiment 1: select each component element and control according to the data in table 1, implement according to the following steps,

[0034] Step A, melting the master alloy: Weighing each high-purity metal Ti, Al, Fe, Cu, Ni, Co, Sn, and adding element Bi, and melting it in an ultra-high vacuum electric arc furnace,

[0035] A1. First, purify various high-purity metals with boron anhydride, and then weigh each high-purity metal according to the atomic percentage in Table 1;

[0036] A2, the various high-purity metals weighed in step A1 are respectively melted according to the combination of Cu-Sn, Cu-Ni, Ti-Al, Fe-Co-added elements, and four groups of master alloys are obtained;

[0037] A3, the four groups of master alloys melted in step A2 are combined according to Cu-Sn and Cu-Ni, Ti-Al and Fe-Co-additional elements for secondary fusion to obtain two groups of secondary master alloys;

[0038] A4, the two groups of secondary master alloys Cu-Sn-Ni and Ti-Al-Fe-Co...

Embodiment 2

[0041] Example 2: According to the steps of the above-mentioned Example 1, the elements and contents of each component are selected according to the data in Table 1, and the surface speed of the roll is controlled at 10m / s, and an amorphous high-entropy alloy with a thickness of about 50 μm can be prepared Brazing foil. Applying the high-entropy alloy solder foil, the T 2 Pure copper and 6061 aluminum alloy are welded, and the tensile and shear strength of the joint is about 139.5MPa, reaching the nominal strength of 6061 aluminum alloy (σ b = 77.5% of 180MPa).

[0042] Table 1 is the data sheet of each embodiment

[0043] Component content

[0044] Example 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap