Method for using anaerobic co-metabolism to process wastewater of coal chemical industry

A technology for coal chemical wastewater and wastewater treatment, which is applied in environmental engineering, chemical wastewater treatment, and municipal engineering fields. Improved oxygen treatment effect, shortened start-up time, and the effect of solving difficulties in anaerobic treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

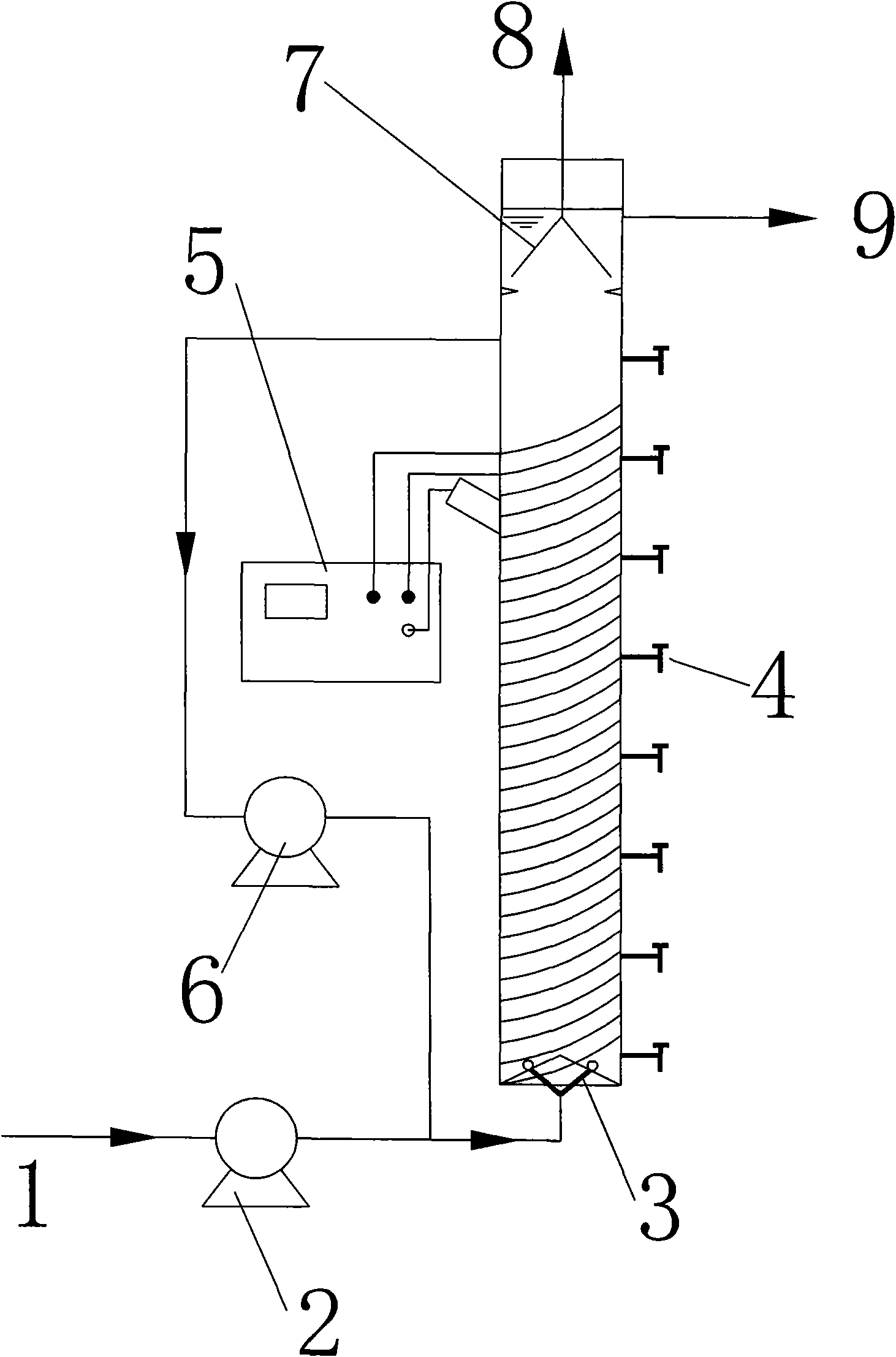

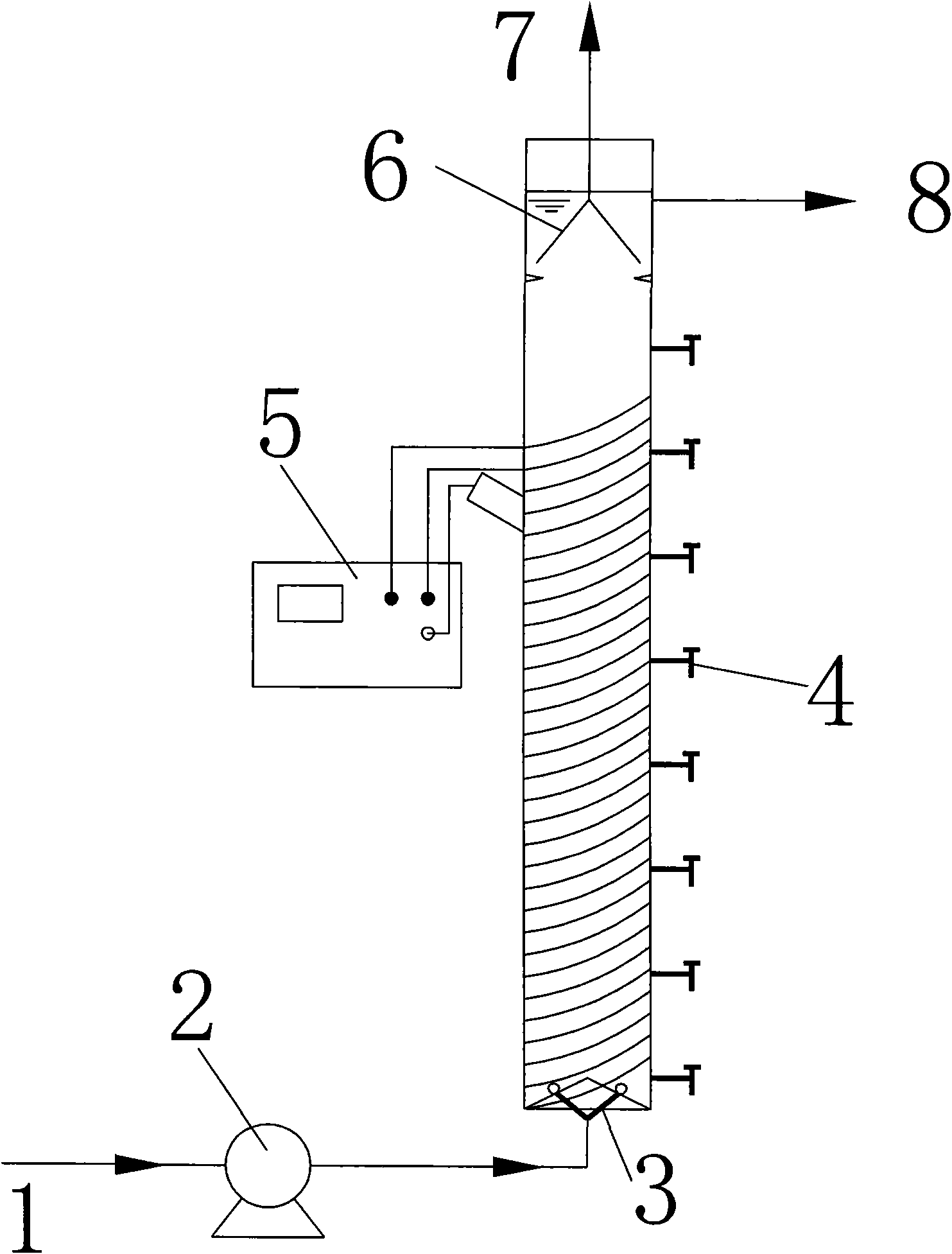

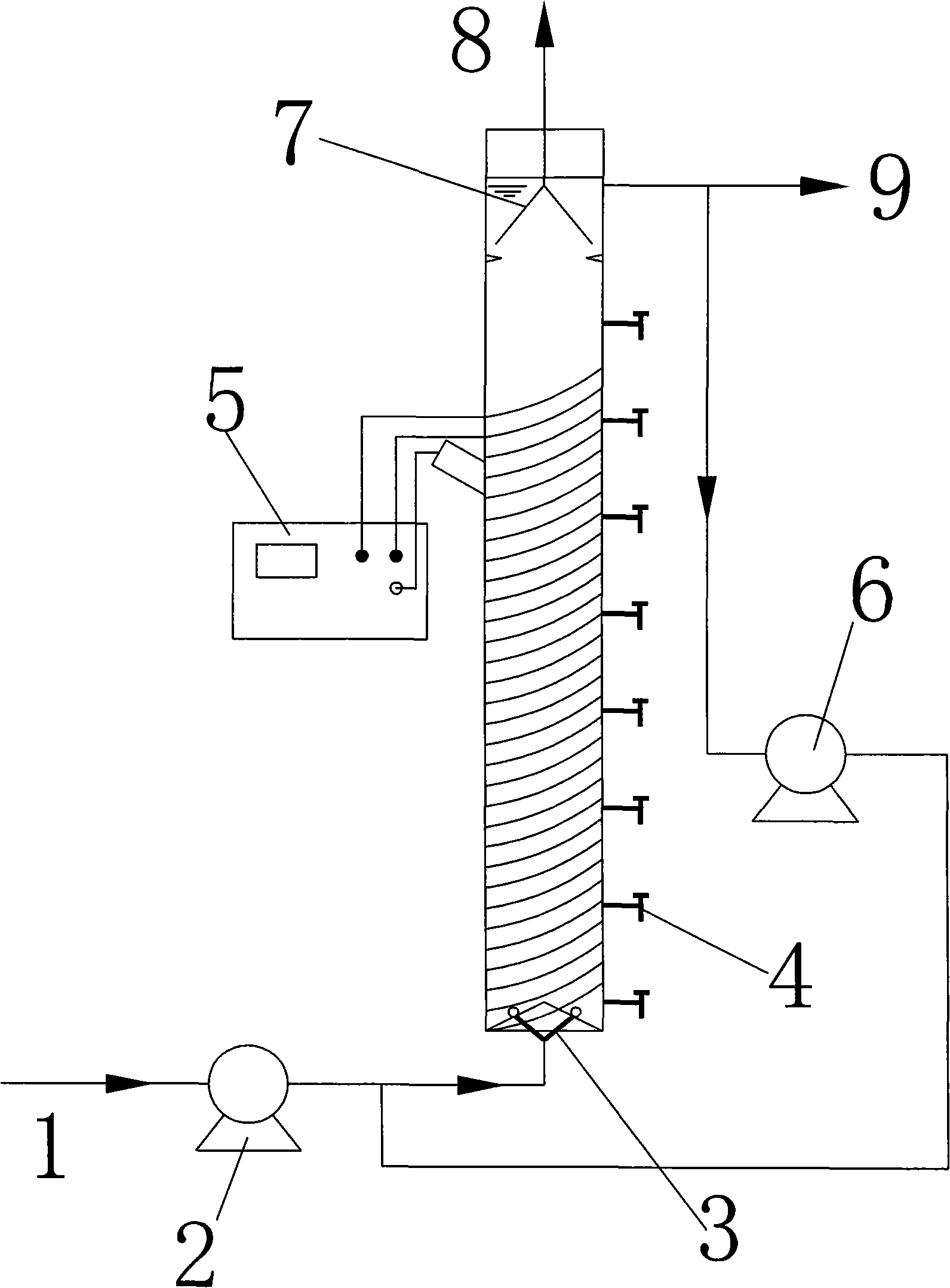

[0014] Embodiment 1: The method for anaerobic co-metabolism treatment of coal chemical industry wastewater described in this embodiment includes the following steps:

[0015] Step 1, selecting coal chemical industry wastewater with phenols as the main pollutants, COD of 3000-4000 mg / L, and total phenol concentration of 600-800 mg / L as wastewater to be treated (raw water);

[0016] Step 2, using anaerobic granular sludge as an initial inoculation mud source, putting the initial inoculation mud source into an anaerobic reactor and settling for 12 to 24 hours; the anaerobic reactor is a medium-temperature anaerobic reactor, That is, keep the temperature in the anaerobic reactor at 32-35°C;

[0017] Step 3: Use methanol as the co-metabolism substrate, add methanol to the wastewater to be treated, and control the ratio of the total amount of COD added by methanol every day (COD equivalent of methanol) to the total amount of COD of coal chemical wastewater treated every day at 0.1~ ...

specific Embodiment approach 2

[0022] Specific embodiment two: In this embodiment, the unit phenol concentration of the coal chemical industry wastewater described in step one is 150-250 mg / L. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Specific embodiment three: present embodiment is in step two, and the inoculum amount of the initial inoculation mud source in the anaerobic reactor is controlled at more than 40gVSS / L (VSS refers to volatile suspended solids). Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com