Method for generating power and supplying heat by utilizing pressure difference of copper electrolysis low-pressure steam

A technology of low-pressure steam and copper electrolysis, which is applied in the direction of photography technology, equipment, photography auxiliary technology, etc., can solve problems such as heat waste, achieve the effects of reducing energy consumption, improving utilization rate, and improving economic benefits of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

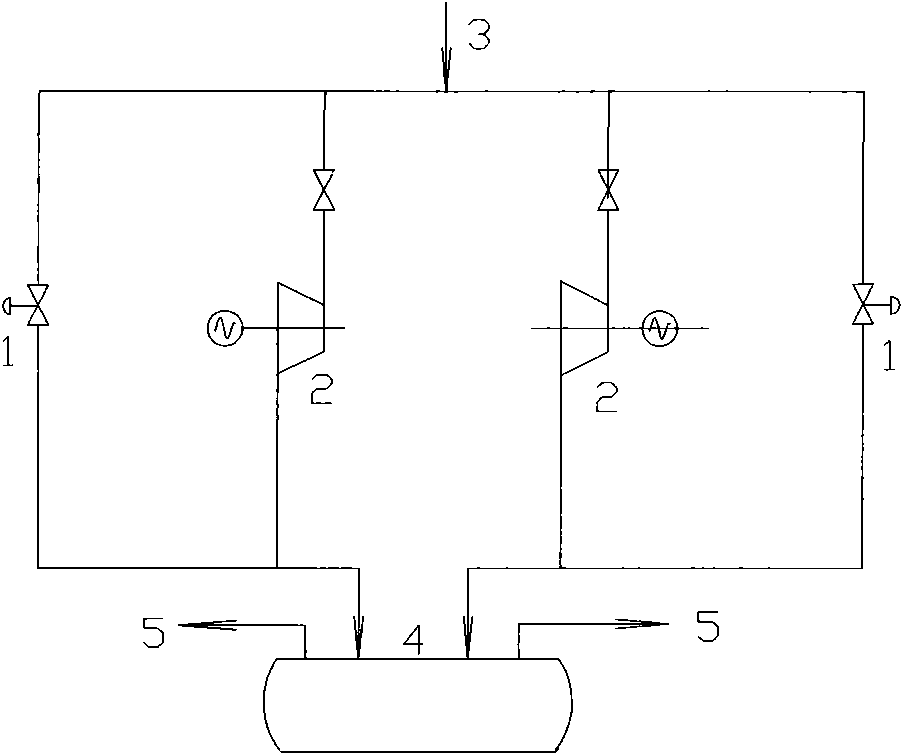

[0009] The embodiment of the present invention is a copper electrolysis workshop steam pressure difference energy recovery power generation. In the production process of the electrolysis workshop, a large amount of low-pressure steam is used. The low-pressure steam is mainly supplied by the low-pressure boiler room and waste heat boiler in the factory area. The steam used in the electrolysis workshop is imported from the factory area. The low-pressure steam pipe network mainly has two main steam pipes for joint steam supply, and the steam supply pressure is 1.0MPa. However, the inlet steam pressure of each steam point in the electrolysis workshop (electrolysis section, clean liquid section, and gold and silver workshop) only needs 0.15 MPa, in order to ensure the inlet intake pressure of the steam point, before the present invention, each steam point inlet was provided with a steam pressure reducing valve, because the pressure reducing valve lost part of the steam energy.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com