Angular momentum mechanism

An angular momentum, inertial body technology, applied in mechanical equipment, transmission, belt/chain/gear, etc., can solve the problems of application limitation, crank connecting rod mechanism cannot be applied to free piston engine, etc., and achieve simple structure and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

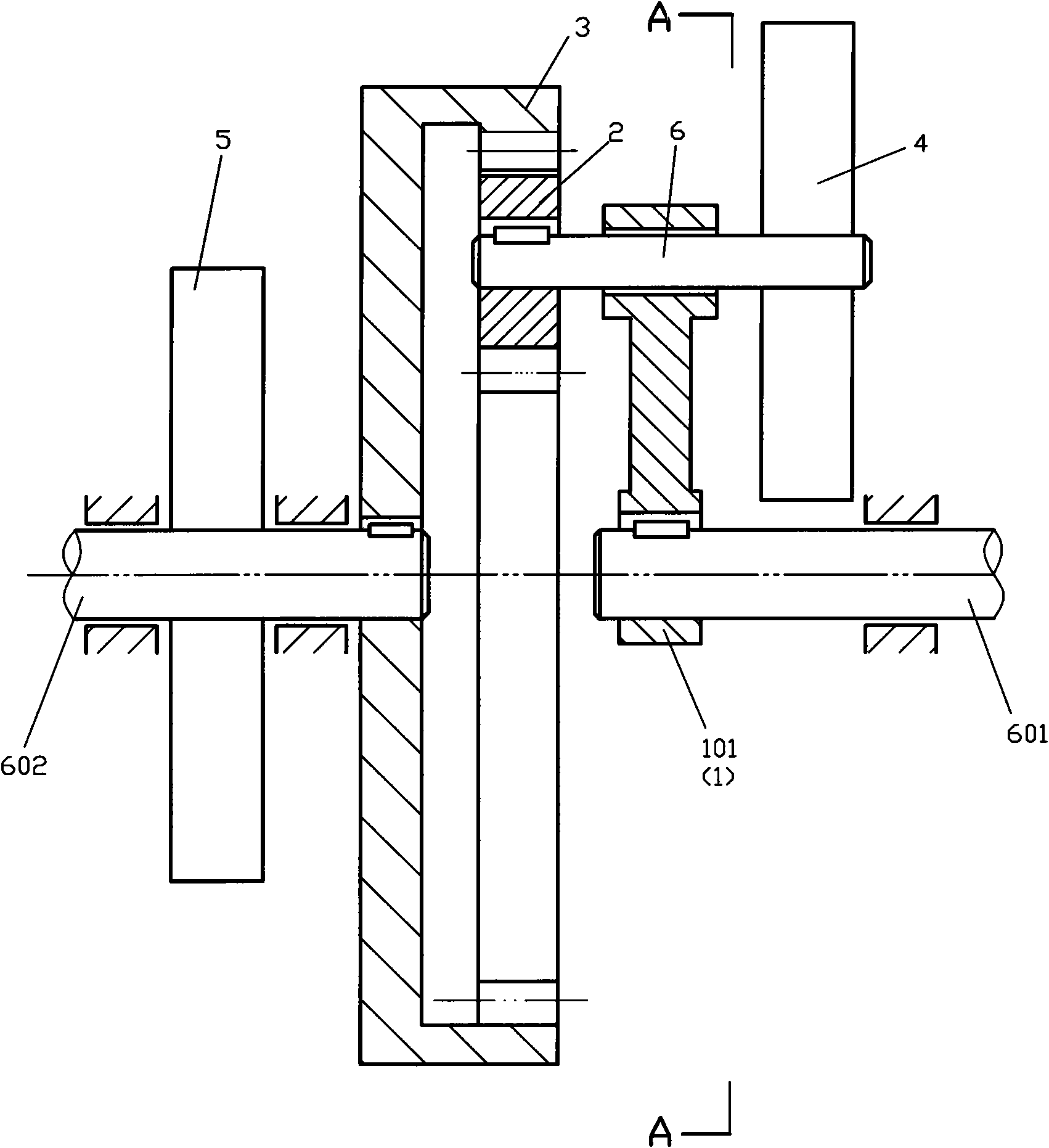

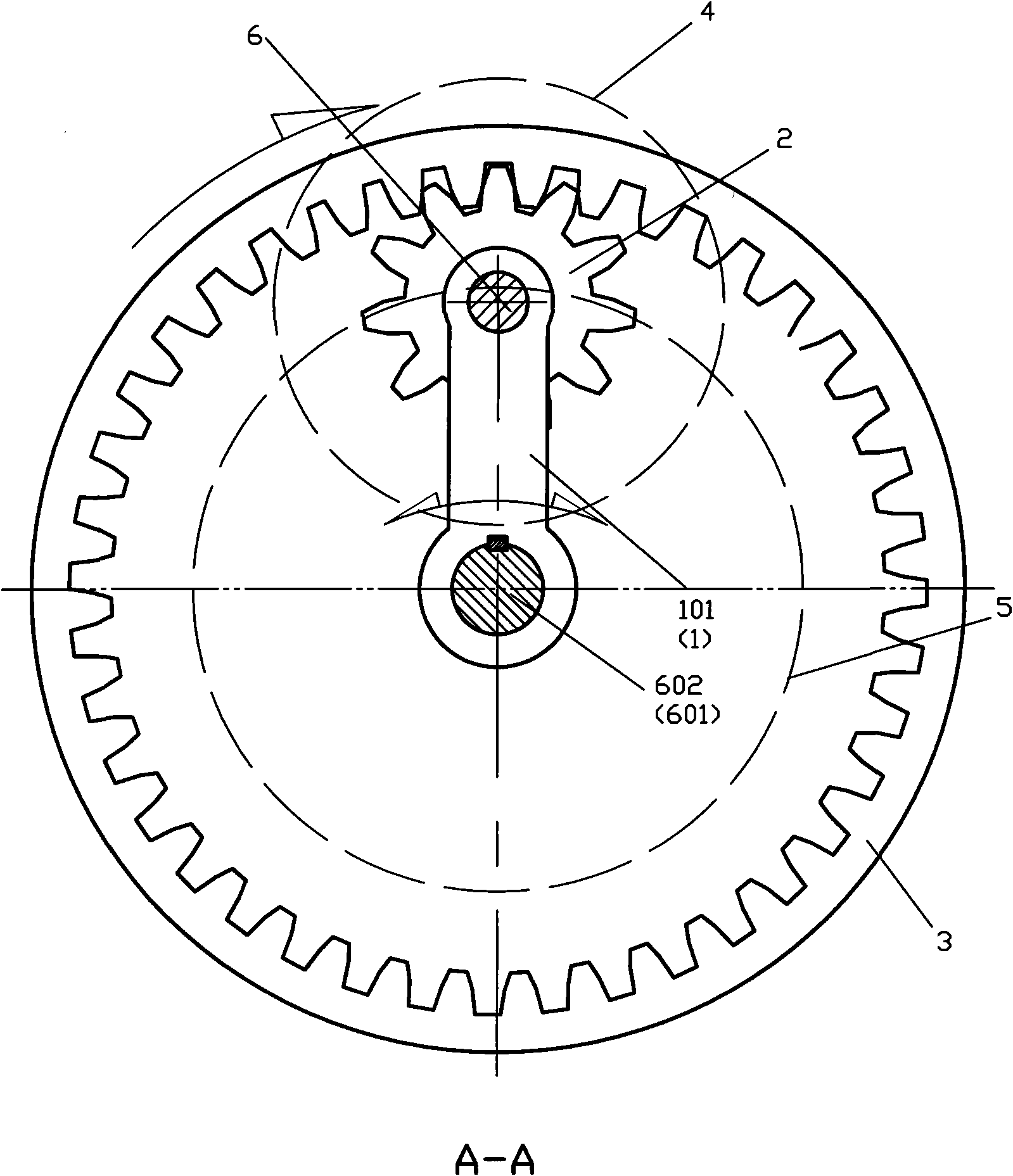

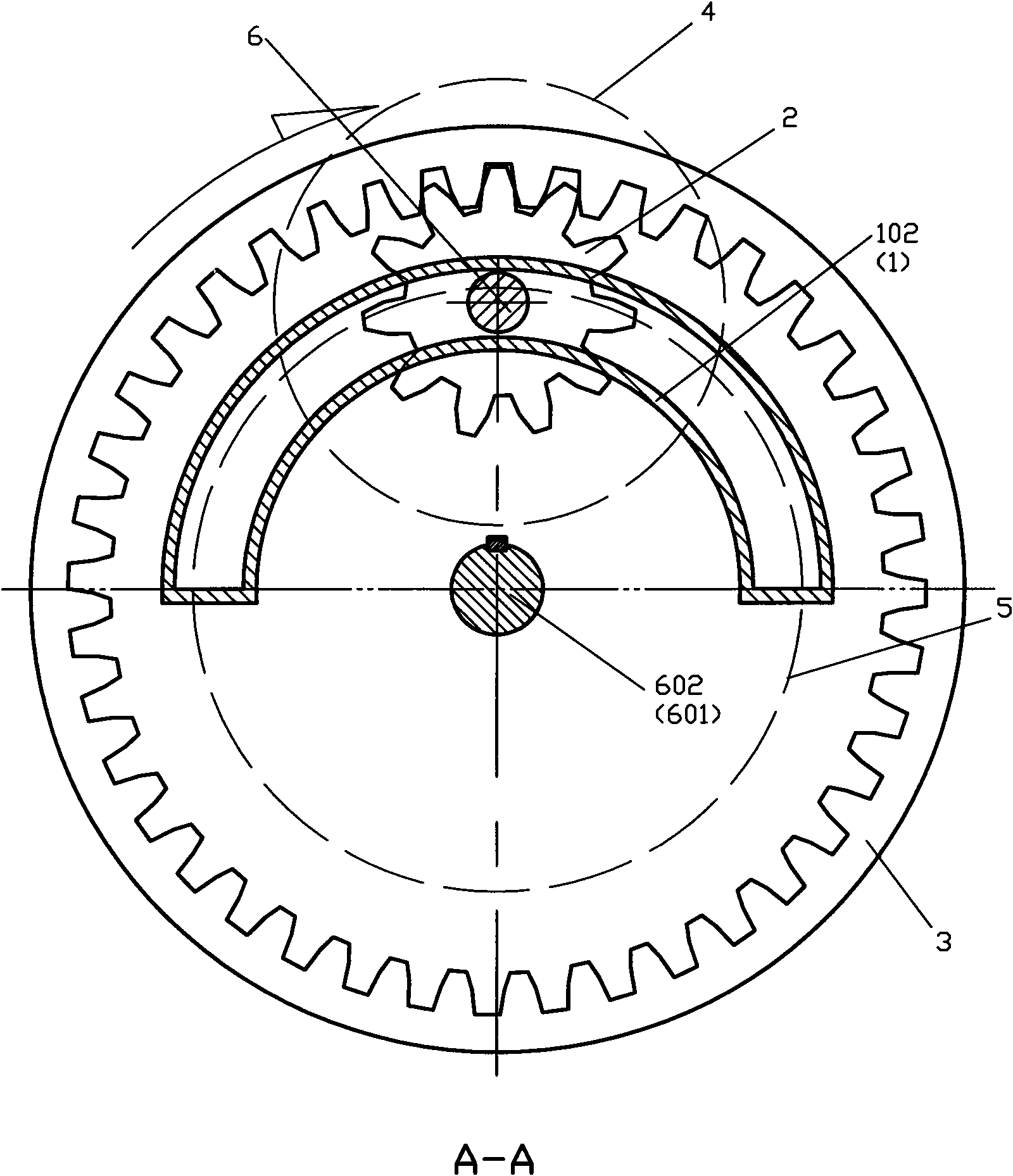

[0038] Figure number

[0039] 1. Revolving structure 2. Planetary gear 3. Sun gear 4. Planetary rotary inertia body

[0040] 5. Center rotating inertia body 101. Revolving arm 102. Revolving arc guide rail 6. Planetary shaft

[0041] 601. Rotary power input shaft 602. Swing power output shaft 501. External gear inertia body

[0042] 502. Combined center rotary inertia body 401. Combined planetary rotary inertia body

[0043] 15. Inertial energy storage structure 16. Elastic body 17. Mass slider 18. Differential

[0044] 20. Planetary gear shaft 21. Planetary gear 22. Side gear A 24. Side gear B

[0045] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

[0046] Please refer to figure 1 , 2 , the angular momentum mechanism shown in 3, 4, 5, 6 and 7, comprising: a revolving structure 1, a planetary gear 2, a sun gear 3 and a planetary mass of inertia 4, characterized in that: the revolving structure 1 is set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com