Heat-transfer pipe of evaporator

A technology for heat transfer tubes and evaporators, applied in evaporators/condensers, heat transfer modification, tubular elements, etc., can solve the problem of large laminar flow on the inner wall of heat transfer tubes, poor refrigeration system efficiency, and low heat transfer efficiency, etc. problem, to achieve the effect of high efficiency of heat transfer process, increase of the number of vaporization cores, and increase of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the above objects, features and advantages of the present invention more comprehensible, preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

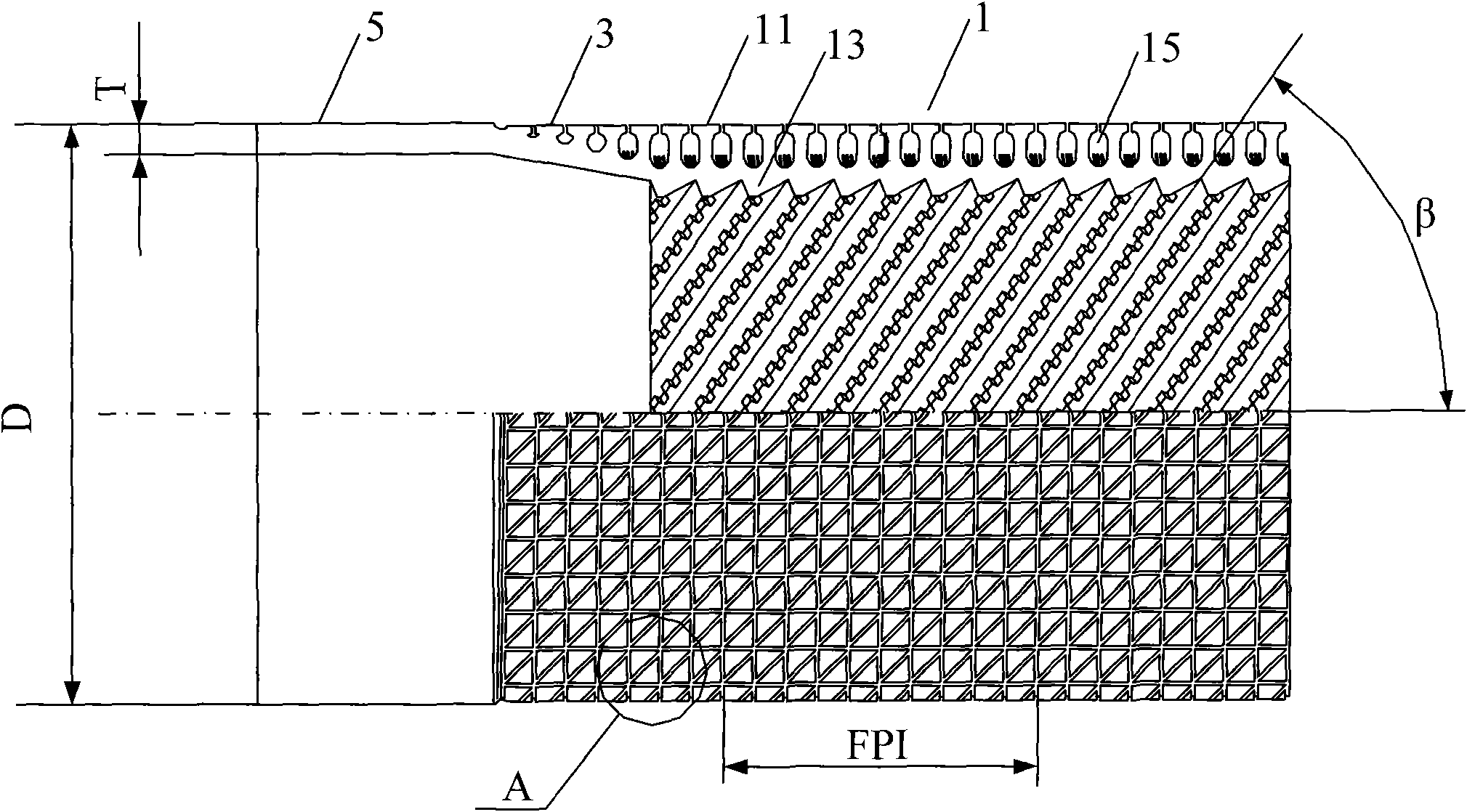

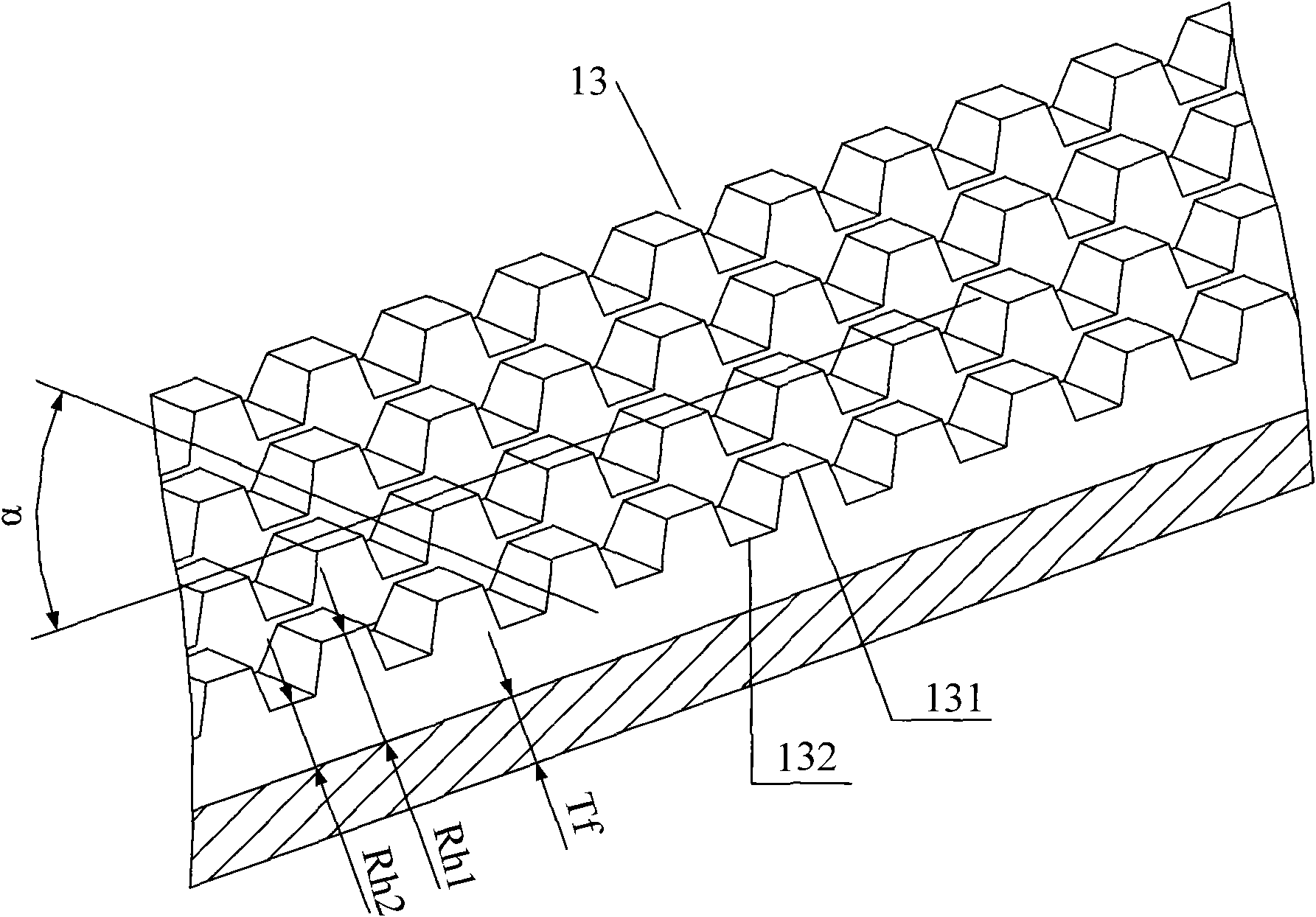

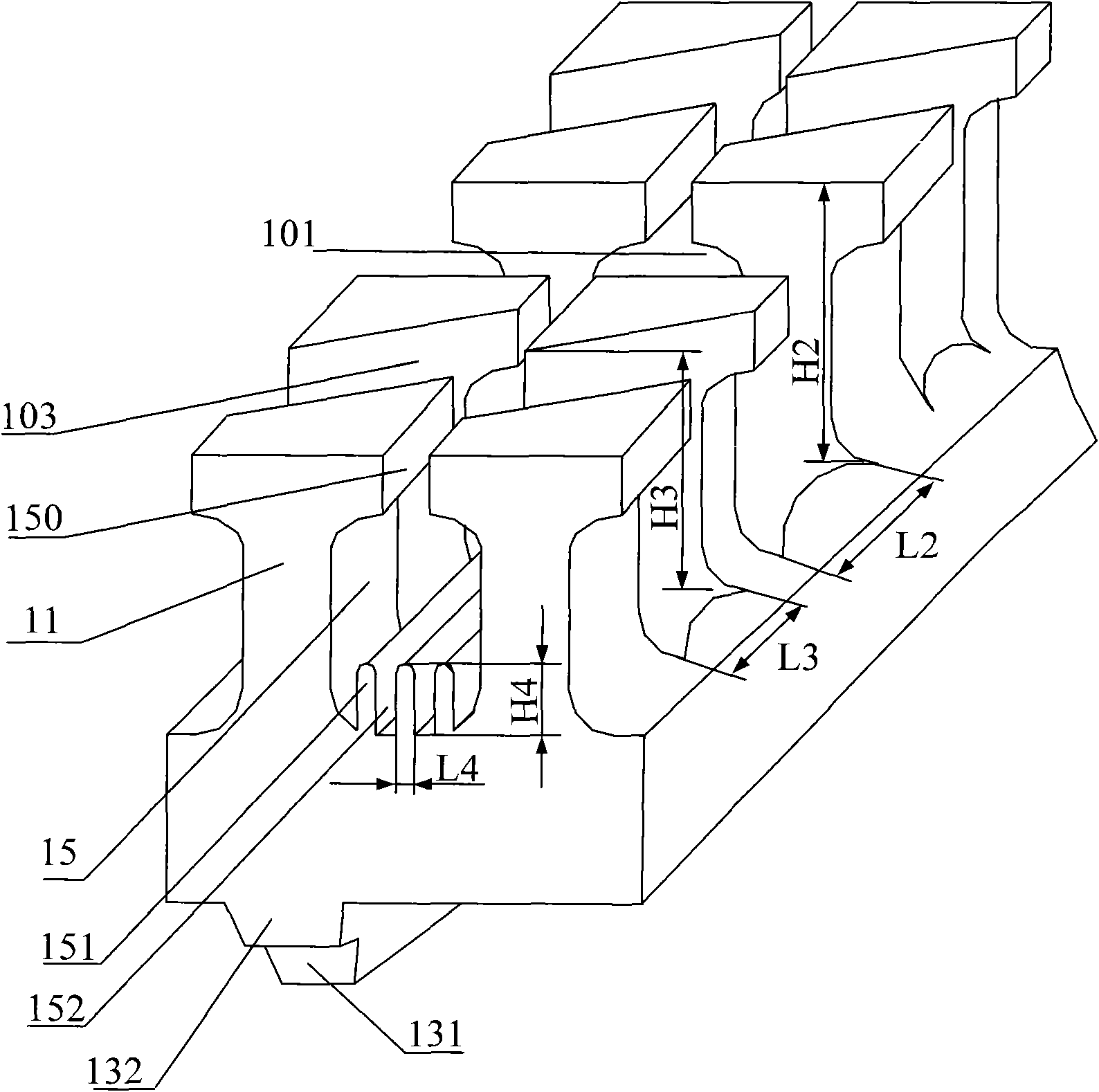

[0024] The invention creates conditions on the outer surface of the heat transfer tube of the evaporator to increase the heat exchange area, increase the number of vaporization cores, maintain the vaporization cores, reduce the heat transfer resistance, and reduce the temperature difference loss, so that the evaporation heat transfer process of the refrigerant tends to be more ideal process. At the same time, by strengthening the turbulence on the inner surface and reducing or reducing the laminar flow effect of the refrigerant, the heat transfer process of the refrigerant is more efficient and tends to an ideal process. By improving and strengthening the comprehensive heat transfer efficiency of the inner and outer surfaces of the heat t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Angle range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com