Device for precise temperature control

A precision adjustment and heating device technology, applied in the direction of temperature control using electric methods, machine operation mode, irreversible cycle compression machines, etc., can solve problems such as insufficient heating capacity, and achieve the effect of saving energy and preventing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

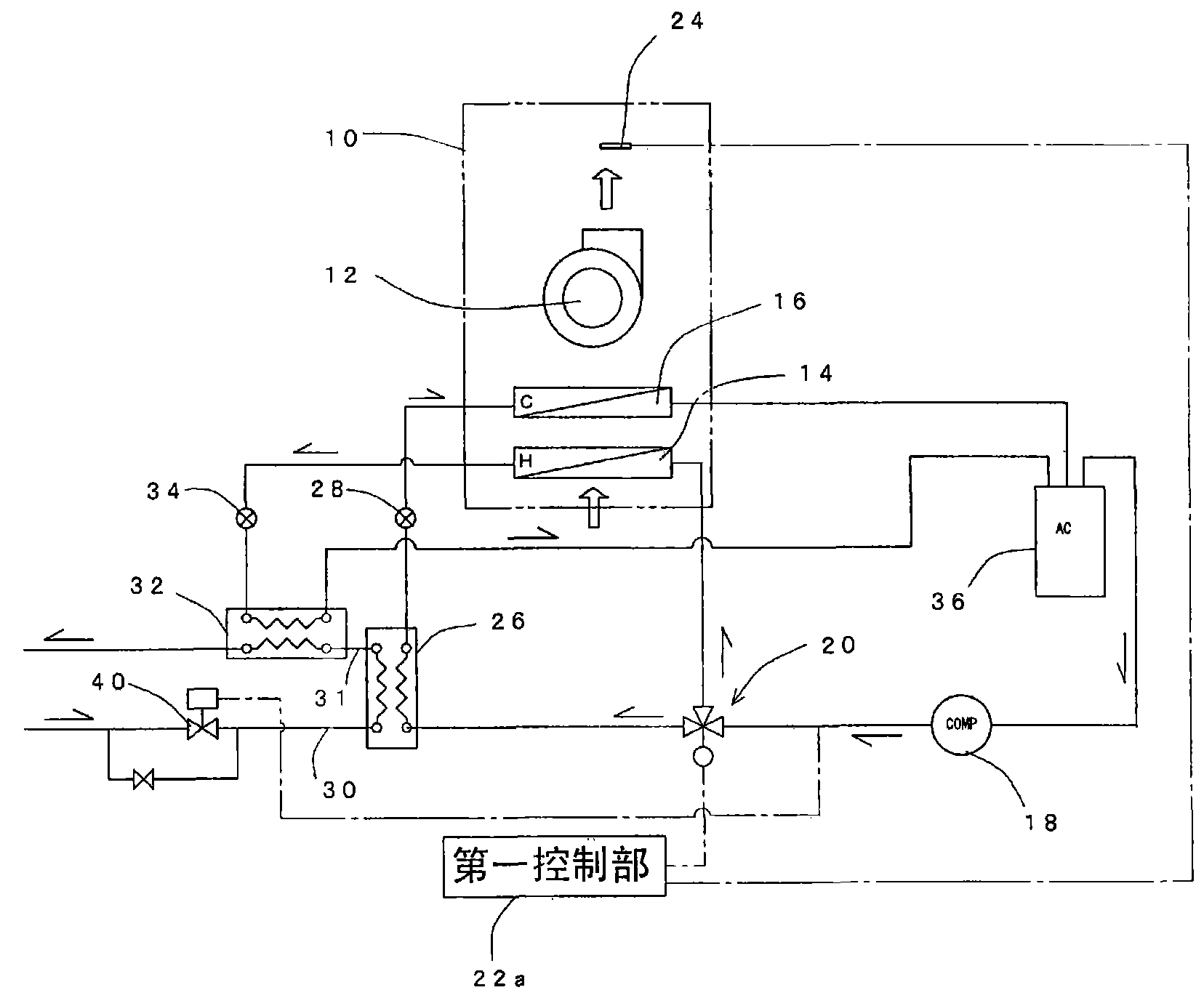

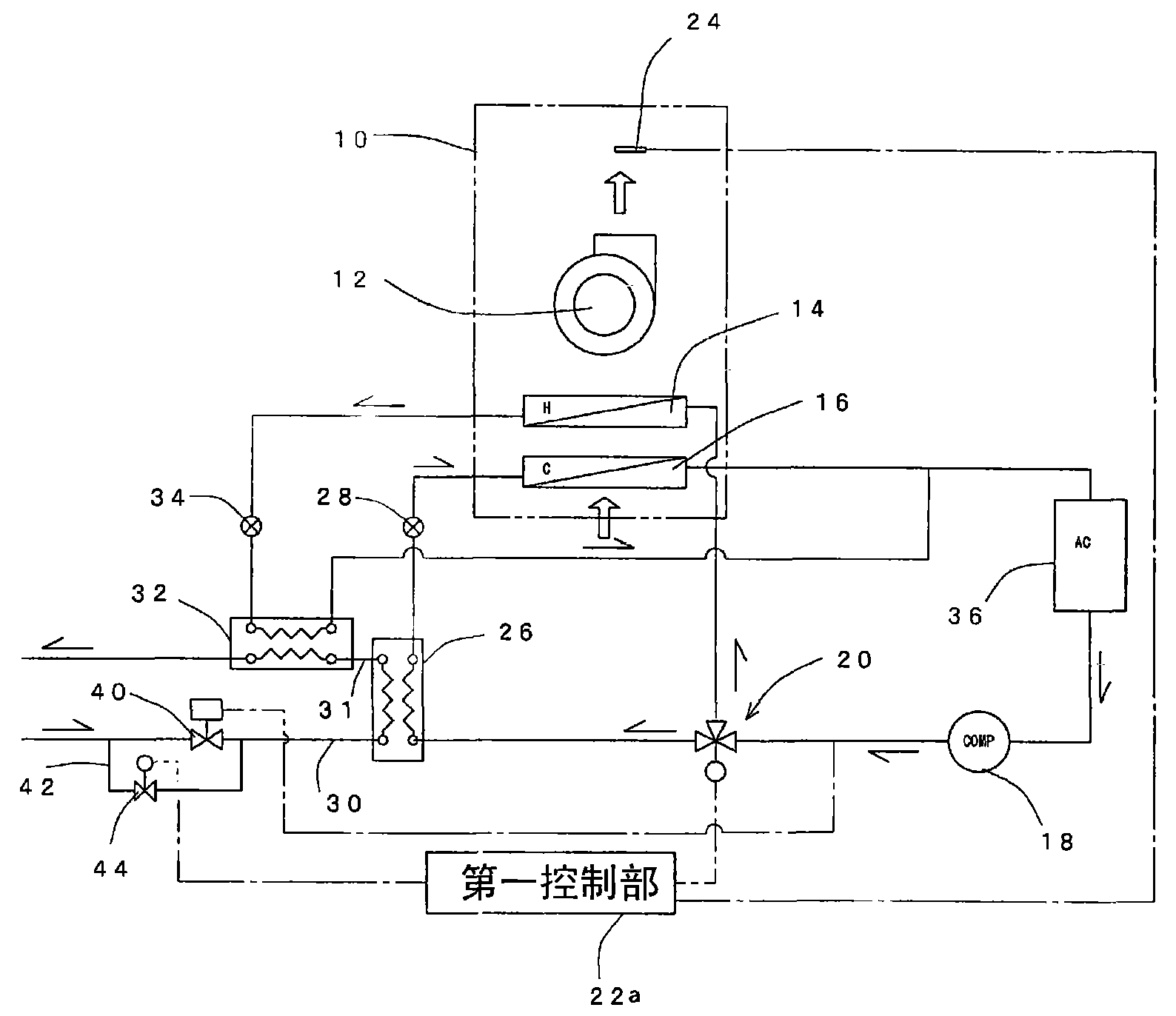

[0056] figure 1 A schematic diagram illustrating an example of an apparatus for finely adjusting temperature according to the present invention is shown. exist figure 1 In the device for finely adjusting the temperature shown, a heating flow path and a cooling flow path are provided in the space unit 10 provided in the temperature-adjusted clean room, and the heating flow path and the cooling flow path are sucked by the fan 12. As a fluid, the temperature and humidity of the clean room are adjusted for more precise temperature adjustment.

[0057] A heater 14 as a heating device constituting the heating flow path and a cooler 16 as a cooling device constituting the cooling flow path are provided, and the air sucked into the clean room in the space unit 10 is cooled and then heated. adjust the temperature accordingly. According to the arrangement of the cooler 16 and the heater 14 with respect to the air flow, the dehumidification effect of the air flow flowing through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com