Automobile braking system based on wire control

An automobile braking system and braking system technology, applied in the field of automobile braking systems, can solve problems such as inconvenient installation, complex structure, and failure to be monitored in real time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Automobile brake system of the present invention comprises following mechanism:

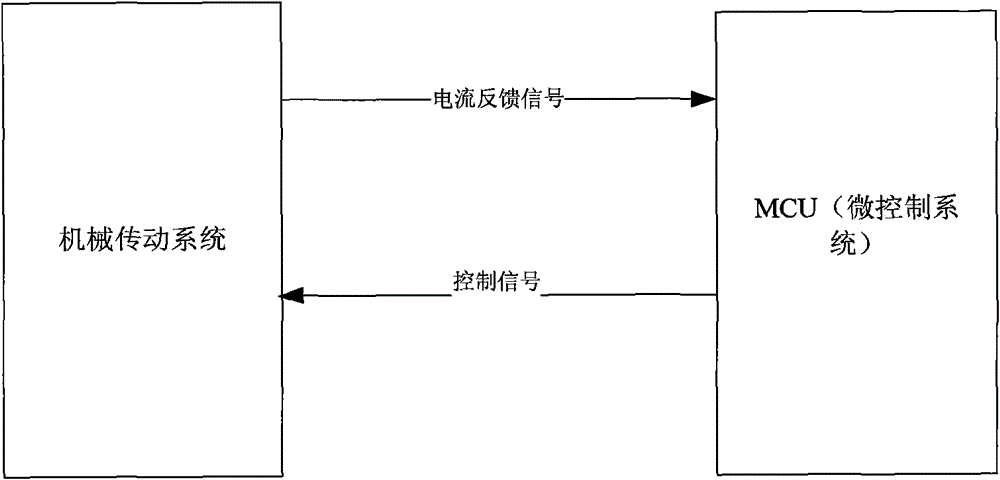

[0013] Microcontroller system (MCU), such as figure 1 As shown, the micro-control system (MCU) collects various signals and obtains the feedback signal of the motor current, and outputs control signals to the mechanical transmission system through the micro-control system (MCU) to control the action process of the mechanical transmission system.

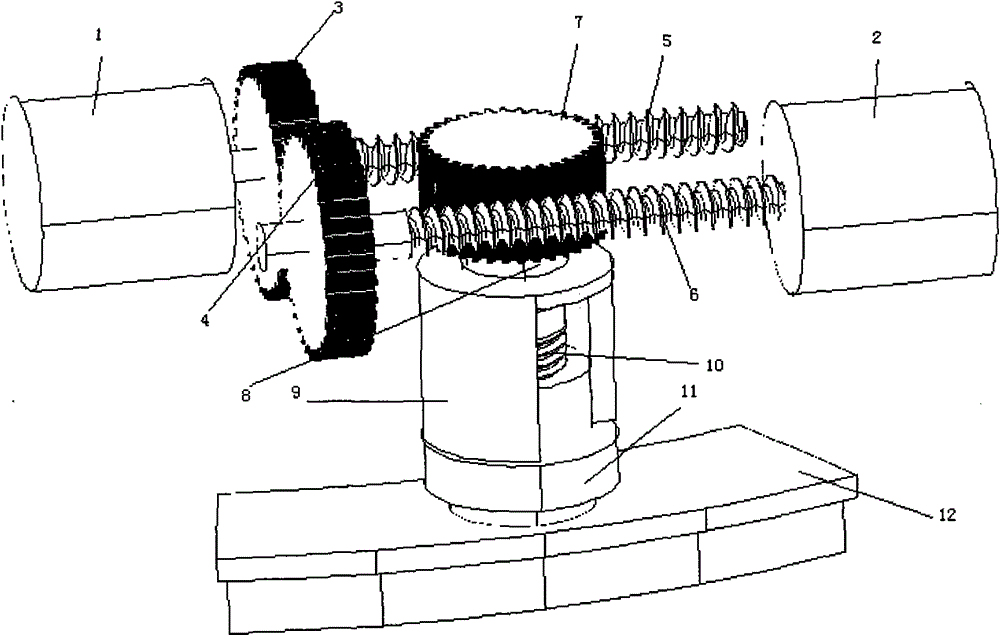

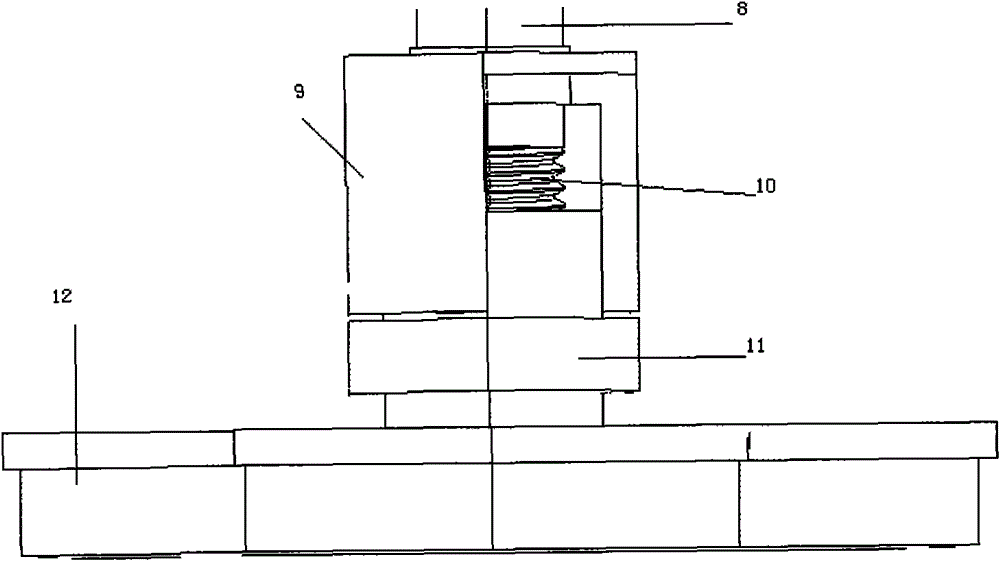

[0014] Drive motor 1 and drive motor 2 are fixedly connected with screw mandrel 5 and screw mandrel 6 respectively, as figure 2 shown. During the running of the vehicle, the drive motors 1 and 2 receive control signals from the embedded control system at any time.

[0015] The gear 3 and the gear 4 are respectively fixed on the screw rod 5 and the screw rod 6 and engage with each other, wherein the screw rod 5 and the screw rod 6 are jointly engaged with the shaft gear 7 front and rear, and the shaft gear 7 is fixed on the brake shaft 8 . Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com