Coating-type binder used for bonding natural rubber and bare steel framework and preparation method

A natural rubber and adhesive technology, applied in the direction of natural rubber adhesives, adhesive additives, adhesives, etc., can solve the problems of adhesive solvents polluting the environment, inability to bond carbon steel bare steel skeleton materials, and poor dynamic mechanical properties

Inactive Publication Date: 2011-01-26

镇江泛华新材料科技发展有限公司

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

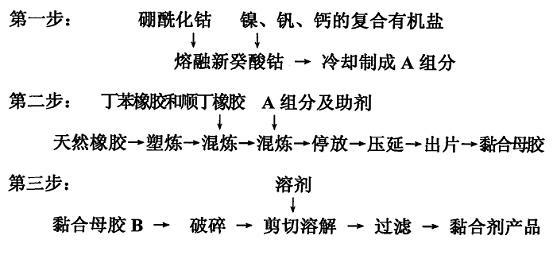

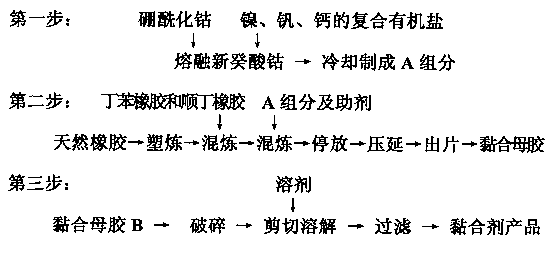

[0004] The technical problem to be solved by the present invention is that the existing cobalt salt adhesives are not suitable for the coating production process and cannot be used for bonding with carbon steel bare steel skeleton materials, while the currently used coating adhesives have Aging and heat aging and poor dynamic mechanical properties, complex and troublesome bonding operations, high cost of use, and environmental pollution from adhesive solvents, provide a direct-added cobalt salt adhesive based on appropriate adhesive promoters, through the improvement Coating-type adhesive for bonding natural rubber and bare steel framework suitable for coating production process and preparation method

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Login to View More

Abstract

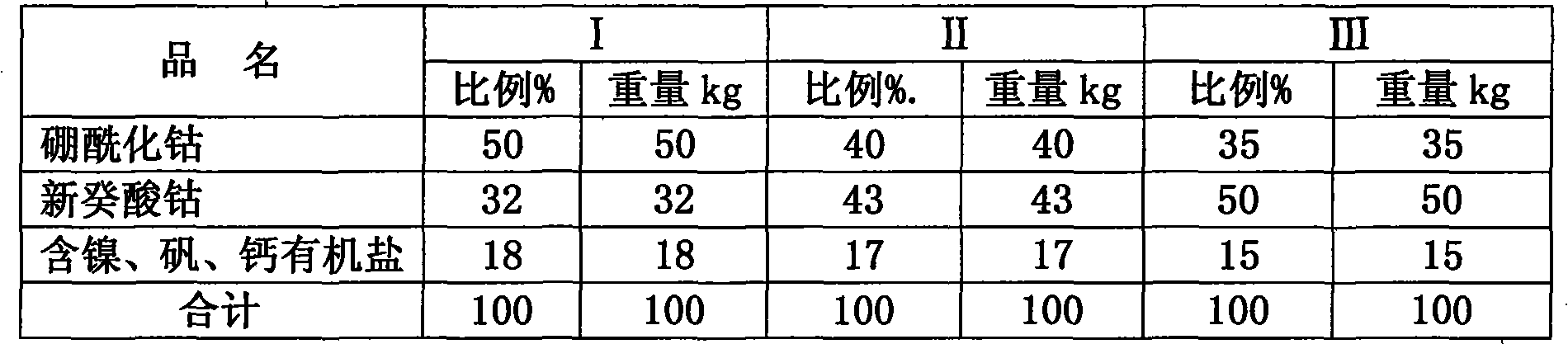

The invention provides a coating-type binder used for bonding natural rubber and a bare steel framework and a preparation method. The coating-type binder is prepared from a composite binder, rubber and an auxiliary agent, wherein the composite binder consists of a main binder and an auxiliary binder which become A component, the main binder consists of cobalt boracyl 23 and cobalt neocaprate and the auxiliary binder is a composite organic salt containing nickel, vanadium and calcium; the rubber is the mixed rubber of natural rubber, styrene-butadiene rubber and cis-butadiene rubber; the auxiliary agent consists of an age resister, a plasticizer, a strengthening agent, an accelerator, a activator and a vulcanizing agent which are of conventional use in rubber product production, A componentis dispersed in rubber material and coordinates with the age resister, the plasticizer, the strengthening agent, the accelerator, the activator and the vulcanizing agent to constitute binding masterbatch B; the binding master batch B is dissolved by solvent of oil to prepare the coating-type binder used for bonding natural rubber and bare steel framework. The coating-type binder of the inventioncan be used in middle-size and small-size rubber product industry, and can also be used on the refurbishment of radial ply tires of steel wires and the production of rubber products such as steel wire reinforcement traveling belt joint glue filling.

Description

technical field [0001] The invention relates to an adhesive, in particular to a coating-type adhesive for bonding natural rubber, general-purpose synthetic rubber and its mixed rubber to carbon steel bare steel skeleton materials with high strength and for bonding natural rubber and bare steel skeleton and its preparation method. Background technique [0002] In the continuous production of large-scale rubber products such as steel radial tires, steel wire reinforced conveyor belts, and steel wire braided rubber hoses, high-strength bonding of elastomers such as rubber and galvanized or brass-plated steel wire cords is required. High-strength bonding. In order to effectively ensure the high-strength adhesion between rubber and this type of metal framework, and to have high anti-aging, heat and oxygen resistance, heat and humidity resistance, and salt water corrosion resistance, the existing technology usually uses a direct-addition cobalt salt adhesive. Add organic acid cob...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09J107/00C09J11/06

Inventor 严忠庆陈秀娟

Owner 镇江泛华新材料科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com