Vapor expander driven air compressor

A technology for driving air and compressing devices, used in machines/engines, mechanical equipment, pump combinations for elastic fluid rotary piston type/oscillating piston type, etc., can solve the problems of compressed air pressure fluctuation, excessive compressed air, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Thus, embodiments of the present invention will be described with reference to the drawings.

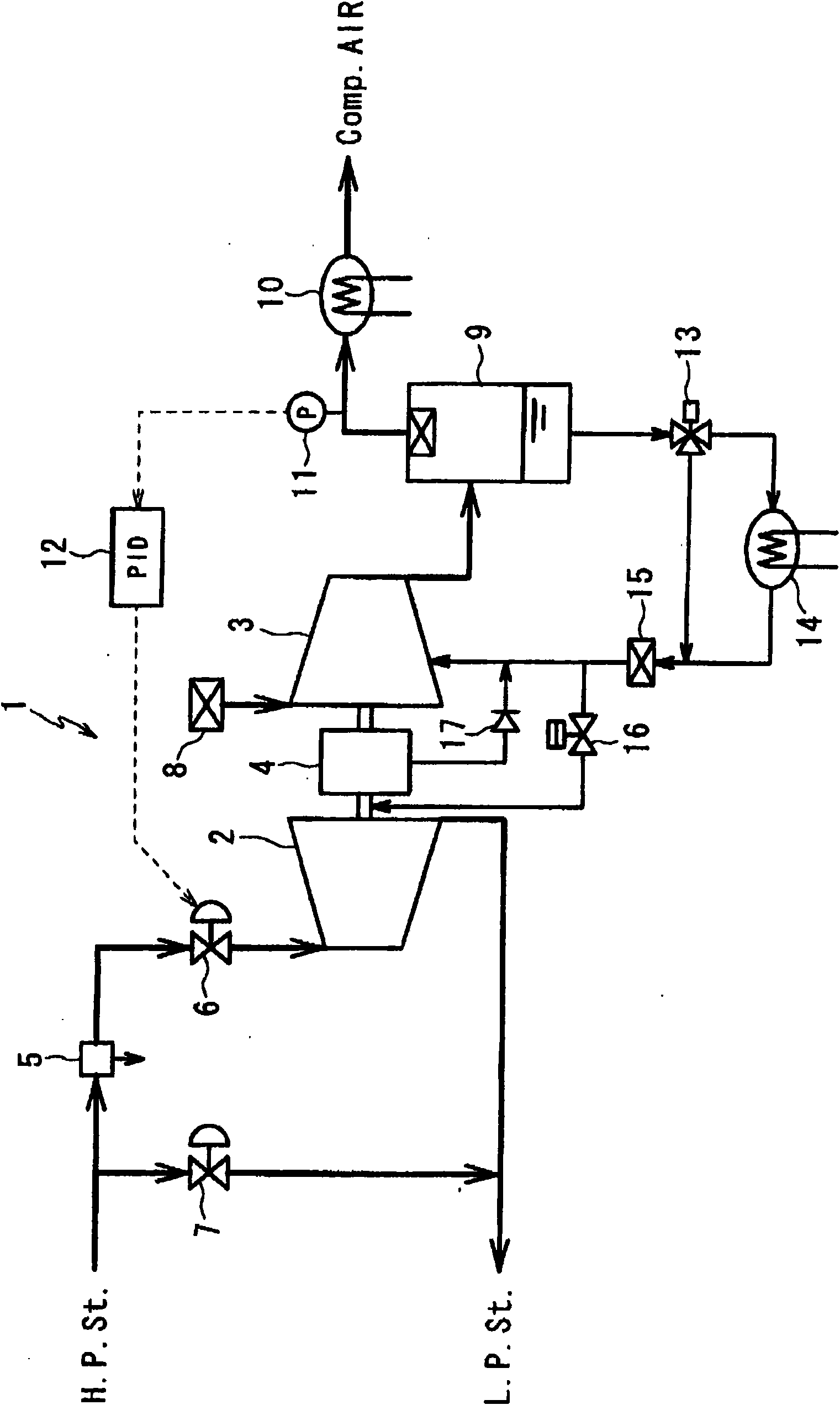

[0021] figure 1 An outline of a steam expander-driven air compression device 1 according to one embodiment of the present invention is shown. The steam expander-driven air compression device 1 has a screw expander (expander) 2 as a volumetric steam expander, a screw compressor 3 as a volumetric air compressor, an output shaft of the screw expander 2 and an input of the screw compressor 3. The shafts are connected via a reducer 4 .

[0022] In the screw expander 2 , high-pressure steam is supplied from a boiler (not shown) via a steam trap 5 and a capacity regulating valve 6 . The screw expander 2 converts the expansion force of the sucked steam into a rotational force, and supplies the low-pressure steam decompressed by the expansion to necessary equipment not shown. In addition, the steam expander-driven air compression device 1 can supply high-pressure steam to the low-pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com