Gas bearing posture active control device

A gas bearing, active control technology, applied in the direction of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of difficult control of the straightness error of the worktable, high requirements for the manufacturing precision of the guide rail, and no error compensation link, and achieves the reduction of Straightness and flatness requirements, improving bearing capacity, and reducing the effect of straightness errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

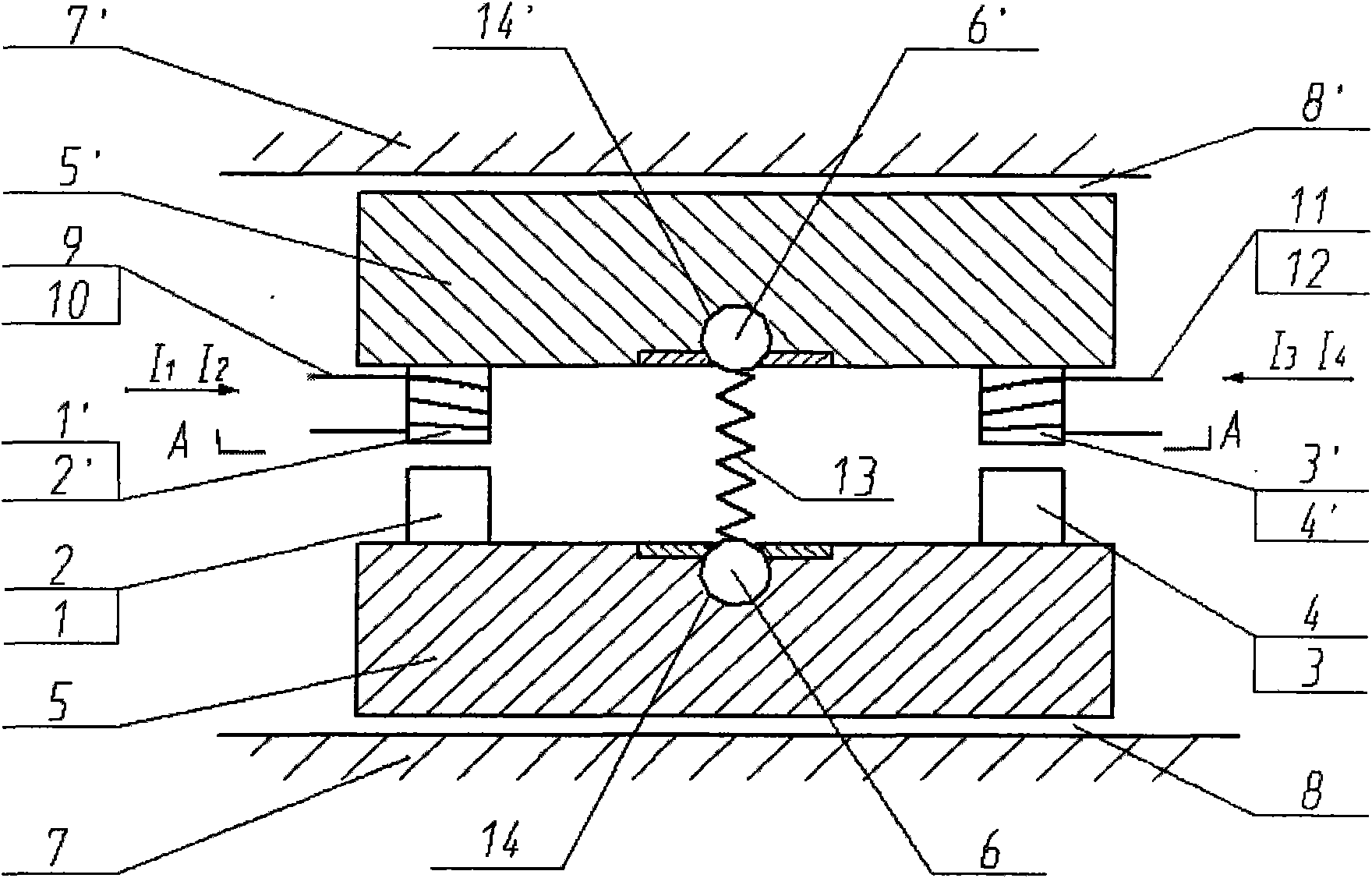

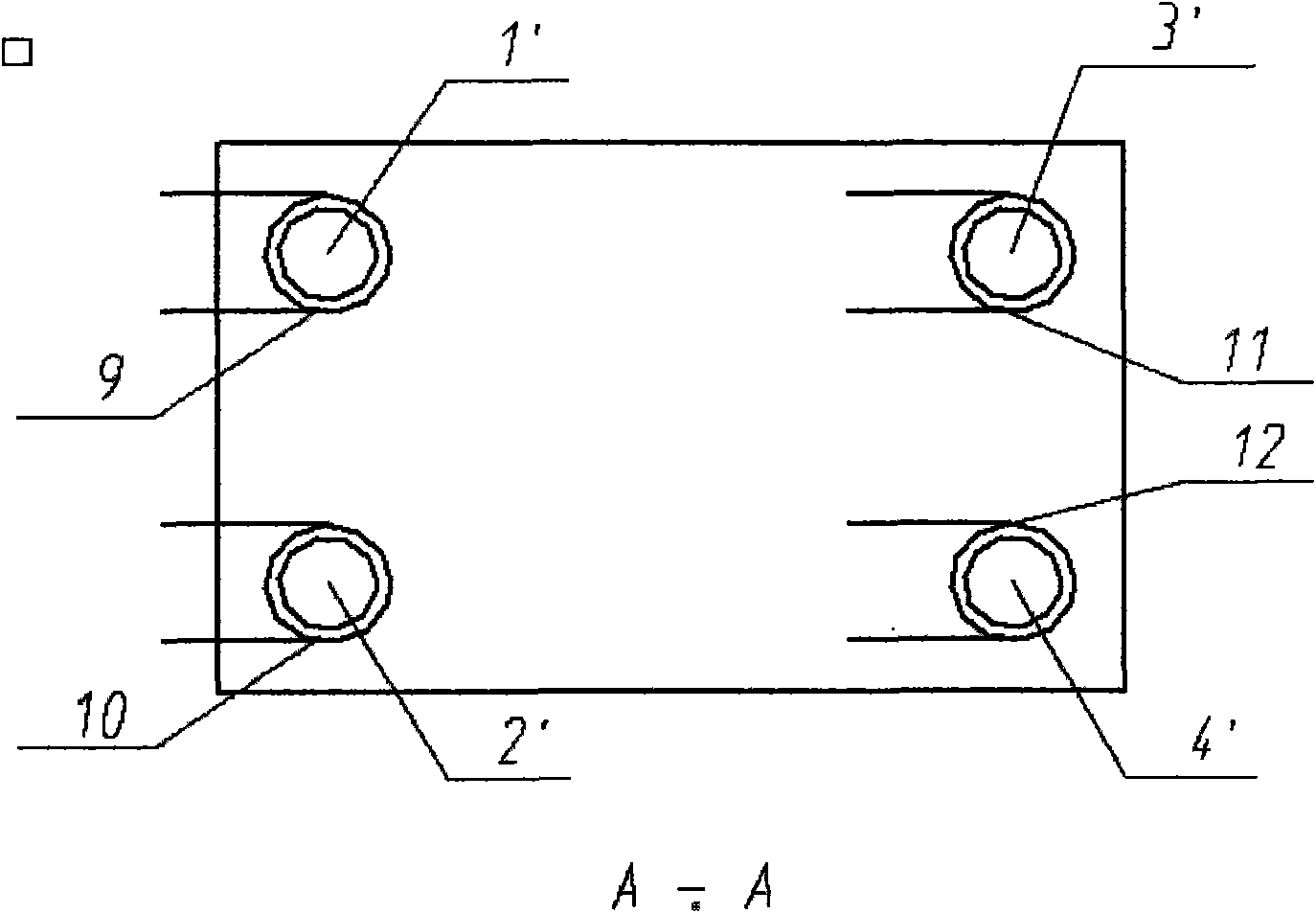

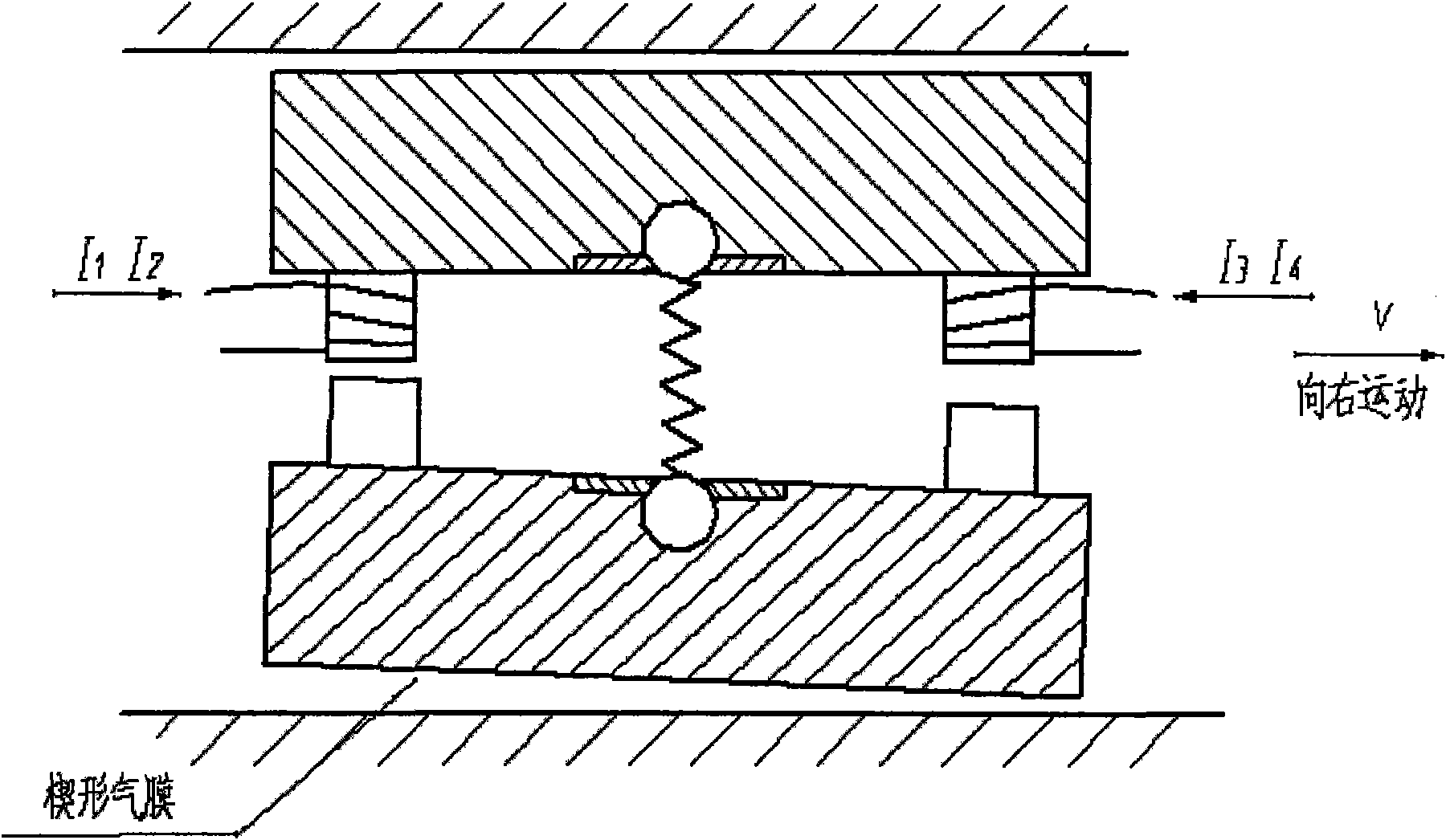

[0016] Such as figure 1 As shown, the structure of the device of the present invention is: gas bearings 5, 5' are installed relatively up and down, the upper bearing 5' is a follower bearing, the lower bearing 5 is an active bearing, and the two bearings are separated by a large rigidity compression spring 13 and pre-set. Tight, large pre-tightening force keeps the air film thickness of the active and follower bearings within a certain range, and the bearings have a large rigidity within this range. The two ends of the compression spring 13 are fixedly connected to the spheres of the spherical joints 6, 6', and the spheres of the spherical joints 6, 6' are installed in the ball sockets 14, 14' of the active bearing 5 and the follower bearing 5' respectively, and the two bearings Can rotate around the ball joint. Four cylinders 1, 2, 3, 4 are installed on the four cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com