Hydraulic valve test platform

A technology of test bench and valve, which is applied in the direction of liquid tightness measurement by using liquid/vacuum degree, and by measuring the increase and deceleration rate of fluid, etc., which can solve the problems of single practicability and single operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

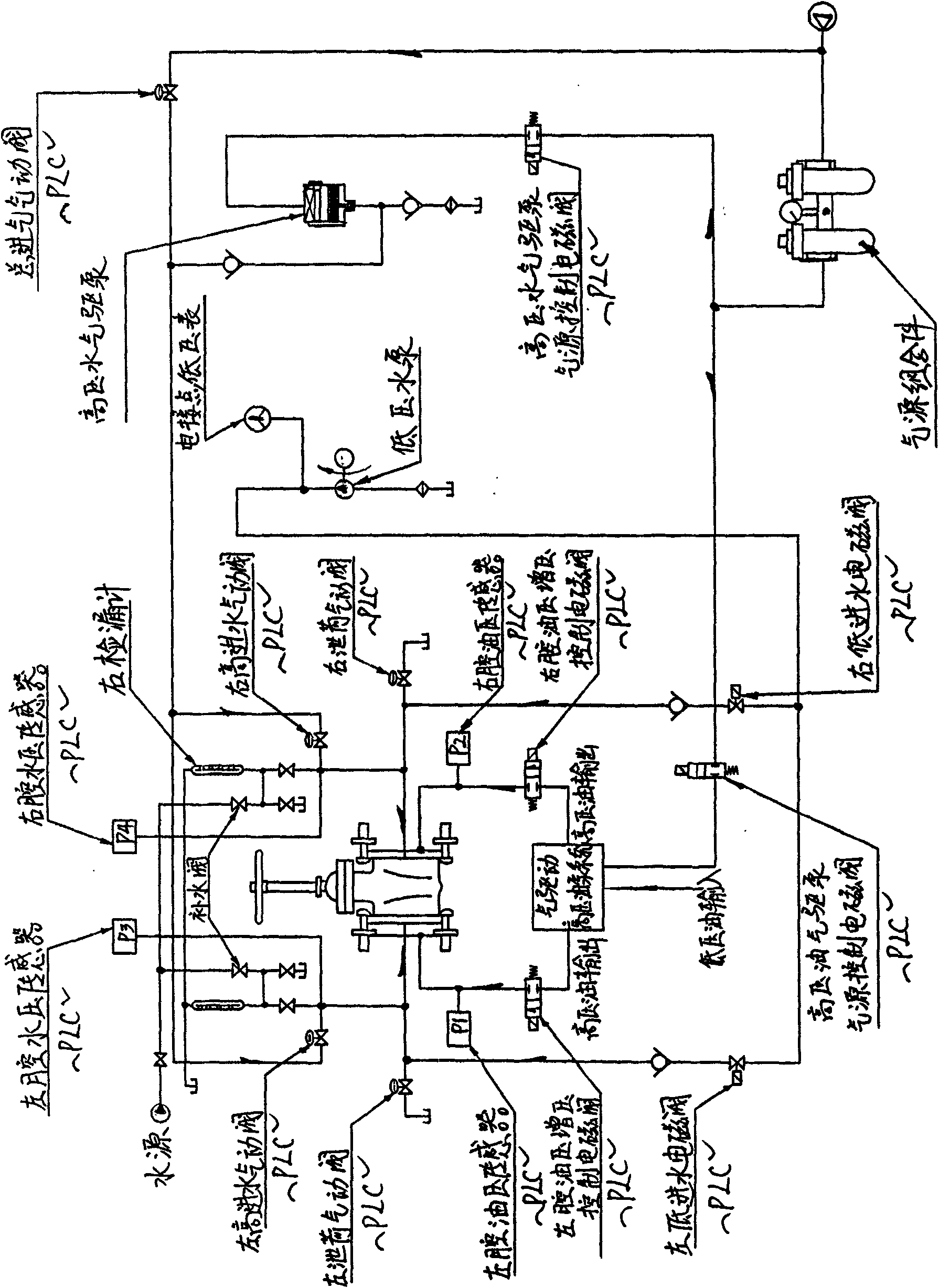

Image

Examples

Embodiment Construction

[0007] The present invention is described in detail below:

[0008] Press the "Test Start" button on the "touch screen" during the upper sealing test, and the system's automatic control program starts: the air-driven pump type "high pressure oil pump" pressurizes the pressure jaw oil cylinder, and the "pressure sensor" transmits the oil pressure value to the "PLC" , when the oil pressure increases to the required value, the "high pressure oil pump" of the hydraulic system stops. If there is a pressure drop during the pressure test, a small difference can be set, and the "high-pressure oil pump" will automatically start to supplement the pressure. When the pressure reaches the required value, the "high-pressure oil pump" will stop. After the pressurization of the jaws is completed, start the "low-pressure water pump" and inject low-pressure water into the inner cavity of the valve. The pump driving type "high-pressure water pump" is started, and high-pressure water is injected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com