Multi-fiber connector and method for fixing aramid fibers of fibers connected thereto

A fiber optic connector and aramid fiber technology, applied in the coupling of optical waveguide, fiber mechanical structure, etc., can solve the problem of large bending curvature and deformation range of single-core optical fiber, affecting the signal transmission effect of the connector, and large optical fiber signal transmission loss, etc. problems, to achieve the effect of avoiding uneven glue application, avoiding glue failure problems, and increasing tensile stress points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

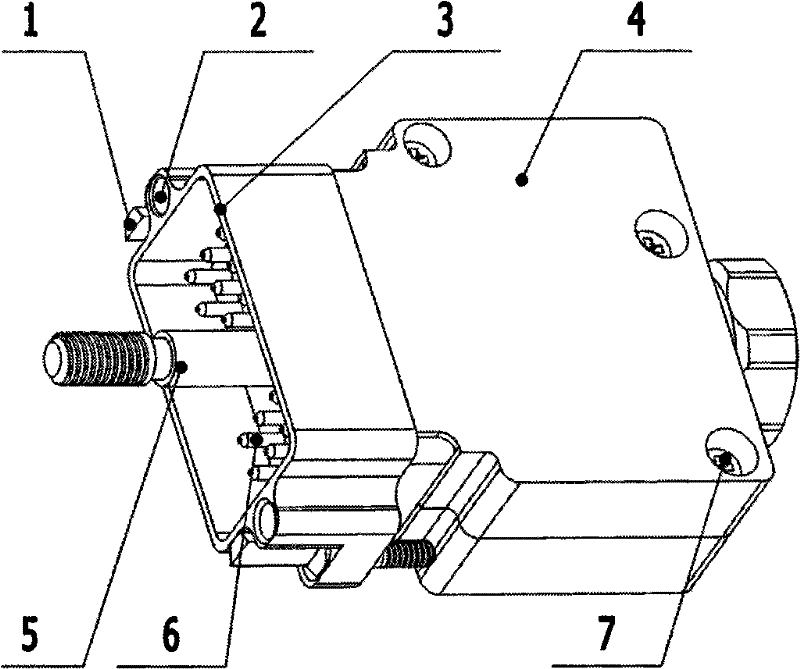

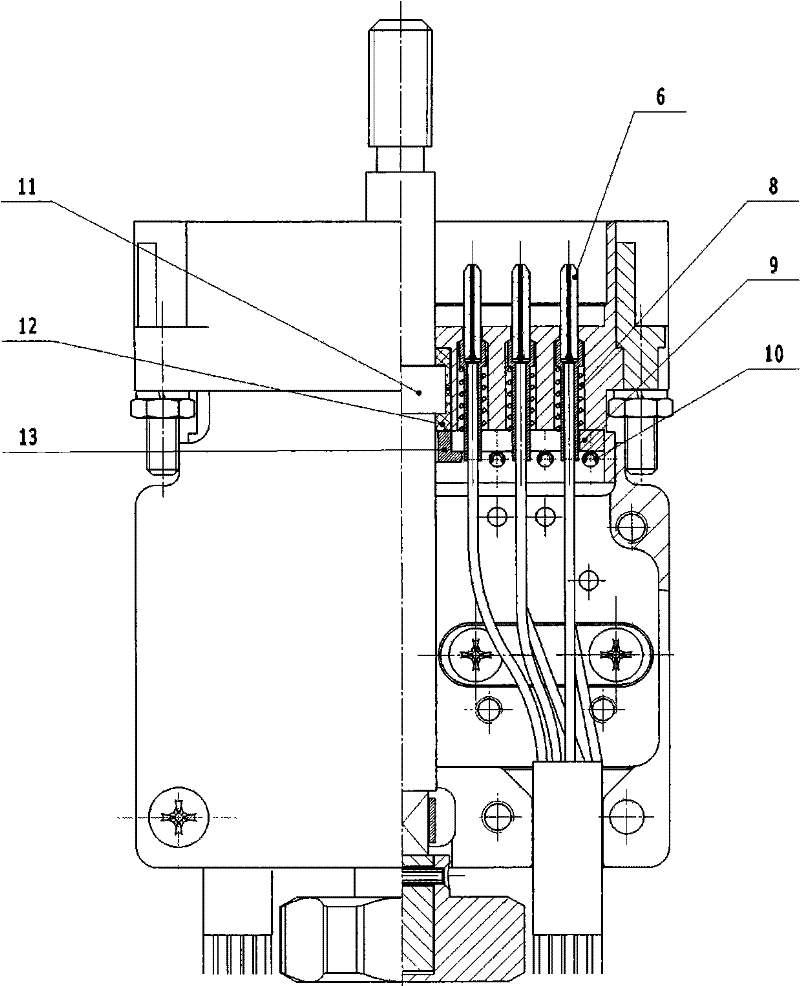

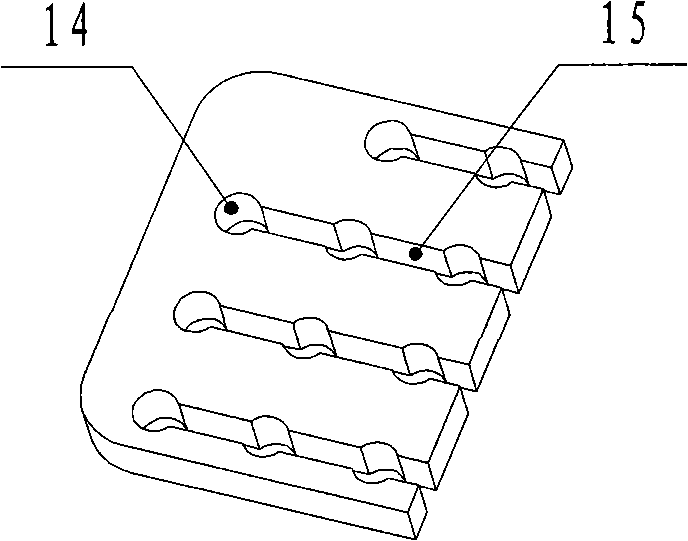

[0029] like Figure 1 to Figure 5 As shown, the embodiment of the multi-core optical cable connector of the present invention is a rectangular multi-core optical fiber connector plug, which includes a connector housing with a plug-in end and an optical cable access end, and the connector housing is formed by the plug-in connector of the head. The part 3 and the tail cover part 4 at the tail part are composed of a plurality of single-core contacts 6 installed in the contact installation cavity provided in the socket part 3, and each optical contact 6 includes pins and pin tails that are fixedly connected. The pin part, the contact part 3 is pressed on the end surface where the inner opening of each contact part is installed, and the contact part pressure plate 9 supporting each optical contact part 6 is pressed, and the pin part and the contact part at the end of each photo contact part 6 Springs 8 are installed on the top between the pressure plates 9, and there are two left a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com