Drive method of photoelectric film transistor, photoelectric sensor and plane display

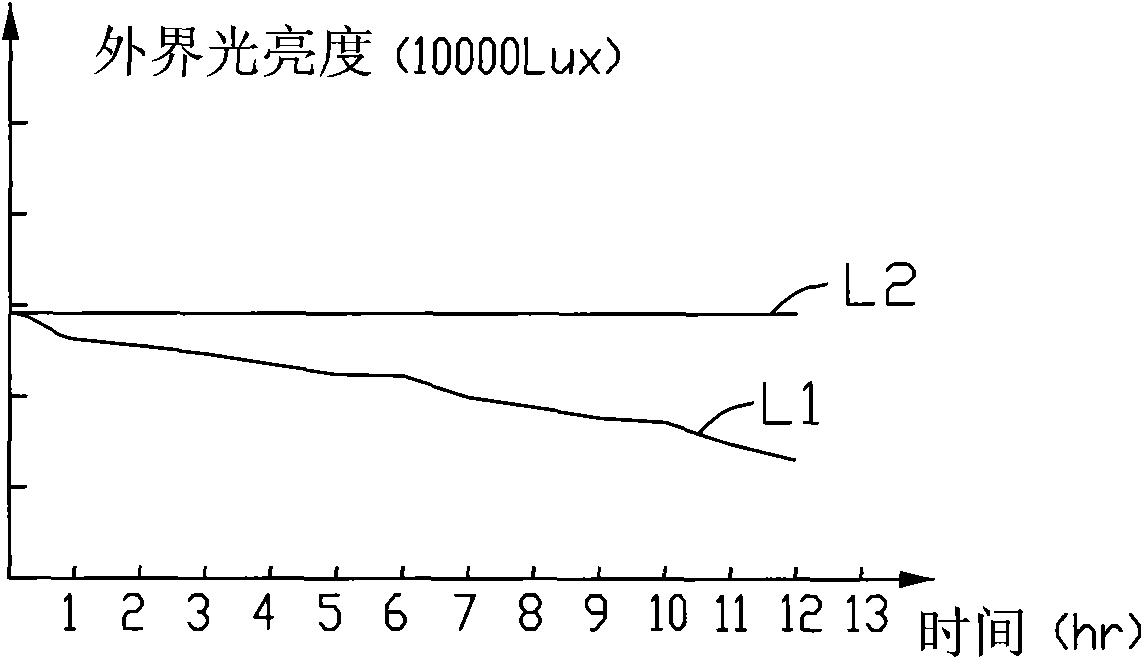

A photoelectric sensor, thin film transistor technology, applied in photometry, static indicators, instruments, etc., can solve the problems of low photoelectric conversion efficiency of photoelectric thin film transistors, low reliability of photoelectric sensors, and low reliability of flat-panel displays, etc. Effects of improved attenuation, improved photoelectric conversion efficiency, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

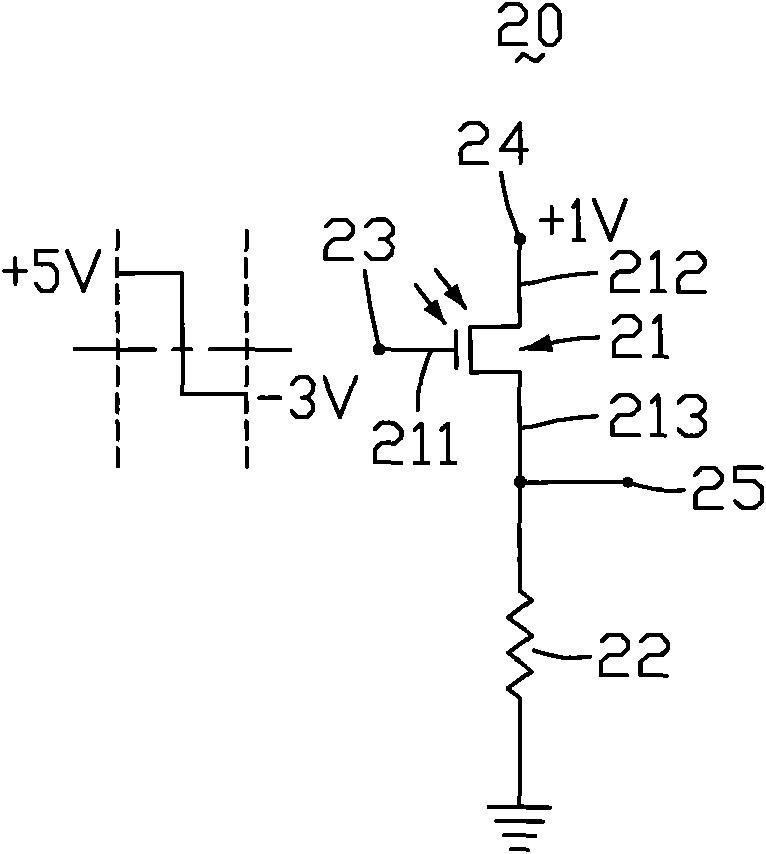

[0022] see figure 2 , which is a schematic circuit diagram of the first embodiment of the photoelectric sensor of the present invention. The photoelectric sensor 20 includes a thin film transistor 21 , a voltage dividing resistor 22 , a first voltage output terminal 23 , a second voltage output terminal 24 and a signal output terminal 25 . The thin film transistor 21 is an amorphous silicon thin film transistor, which includes a gate 211 , a source 212 and a drain 213 . The gate 211 is connected to the first voltage output terminal 23 , the source 212 is connected to the second voltage output terminal 24 , the drain 213 is connected to the signal output terminal 25 , and grounded via the voltage dividing resistor 2 .

[0023] The first voltage output terminal 23 and the second voltage output terminal 24 respectively output a first voltage and a second voltage to the gate 211 and the source 212 to drive the thin film transistor 21 .

[0024] The first voltage output terminal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com