Process and apparatus for producing carbonaceous film

A manufacturing method and carbonaceous film technology, applied in metal material coating process, coating, gaseous chemical plating, etc., can solve the problems of large-scale, increased equipment cost, unfavorable energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Next, preferred embodiments of the present invention will be described. Among them, matters other than those specifically mentioned in this specification and necessary for the implementation of the present invention can be understood as matters designed by those skilled in the art based on the prior art in this field. The present invention can be implemented based on the content disclosed in this specification and common technical knowledge in the field.

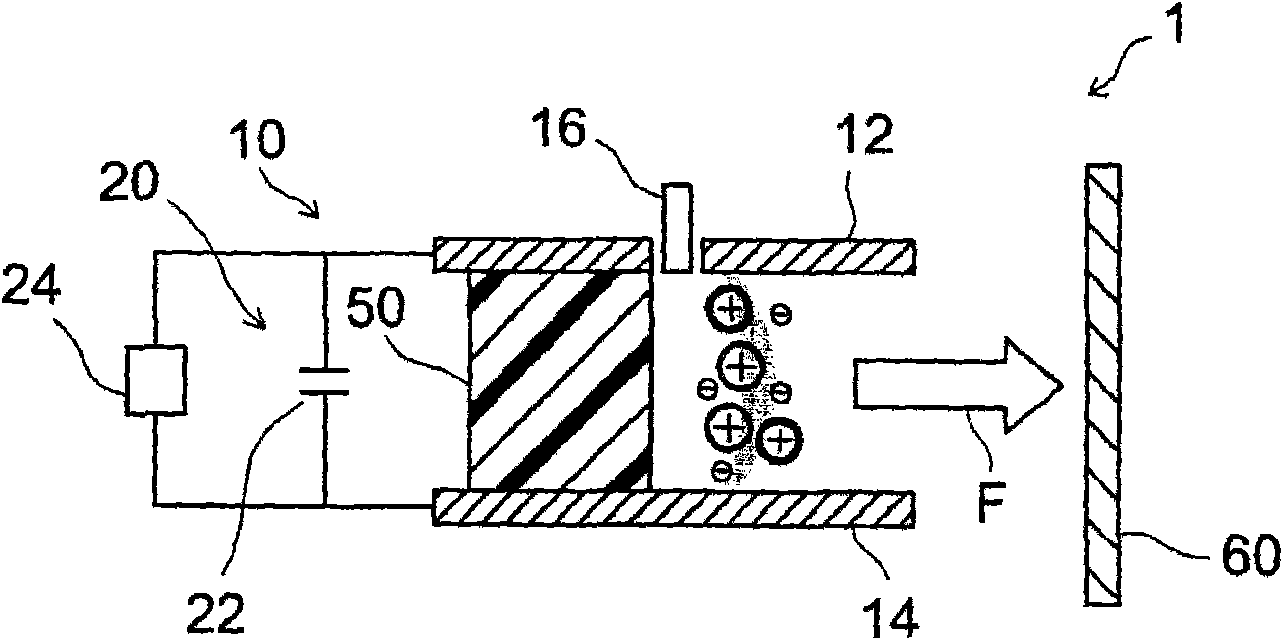

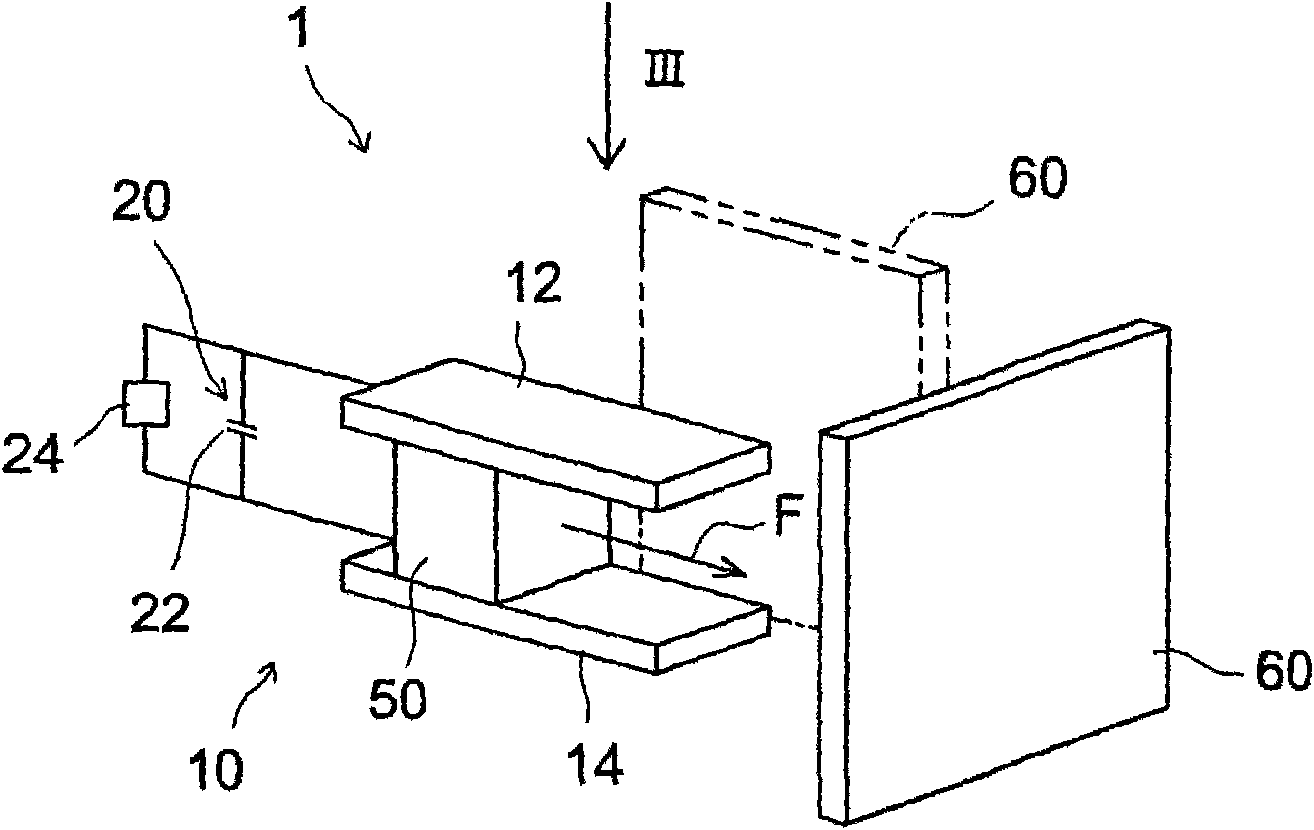

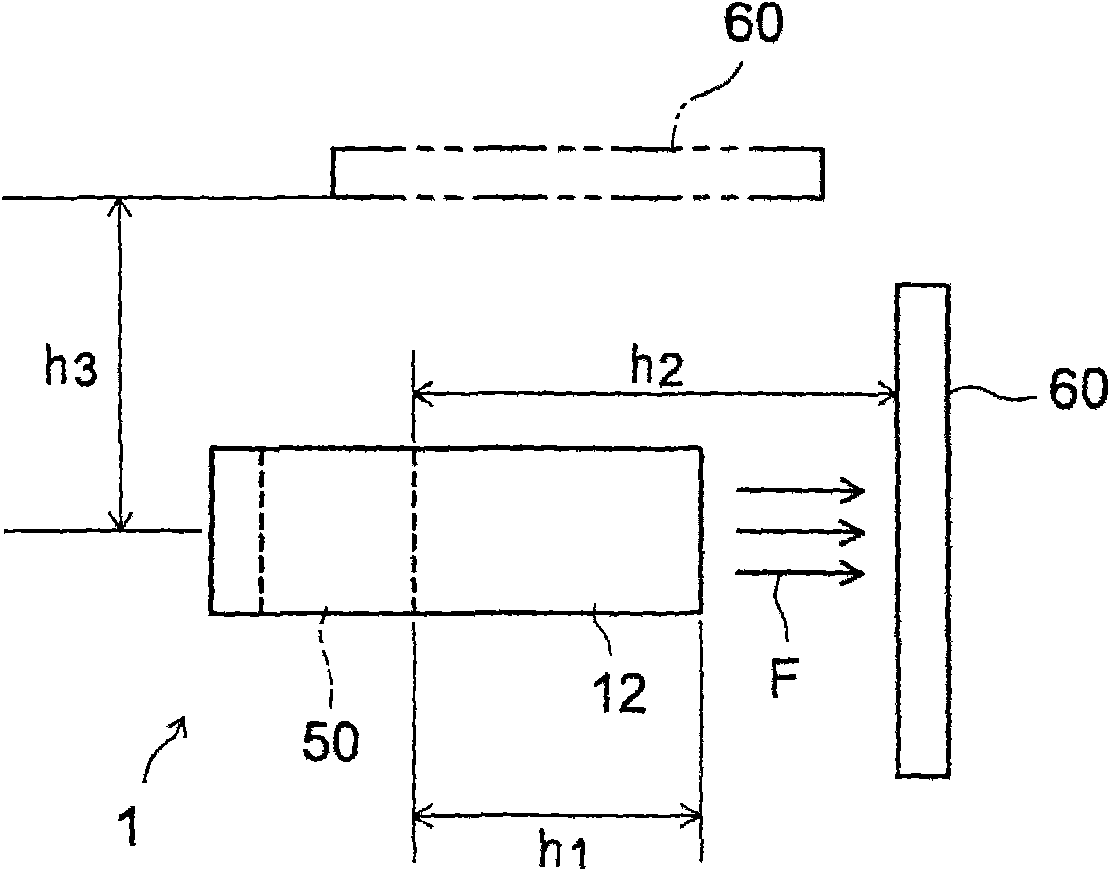

[0048]In the technique disclosed here, as a raw material (which can be understood as a film forming material, a plasma source, a carbon source, etc.), an organic compound containing a carbon atom (C) (typically containing carbon (C) and other elements such as Hydrogen (organic compound of H)) is an organic material whose main component is solid as a whole. As the above-mentioned organic compound, an organic compound having a molecular weight (may be understood as an average molecular weight) of at least 100 and being...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com