Improvements in cyclical swing absorption processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

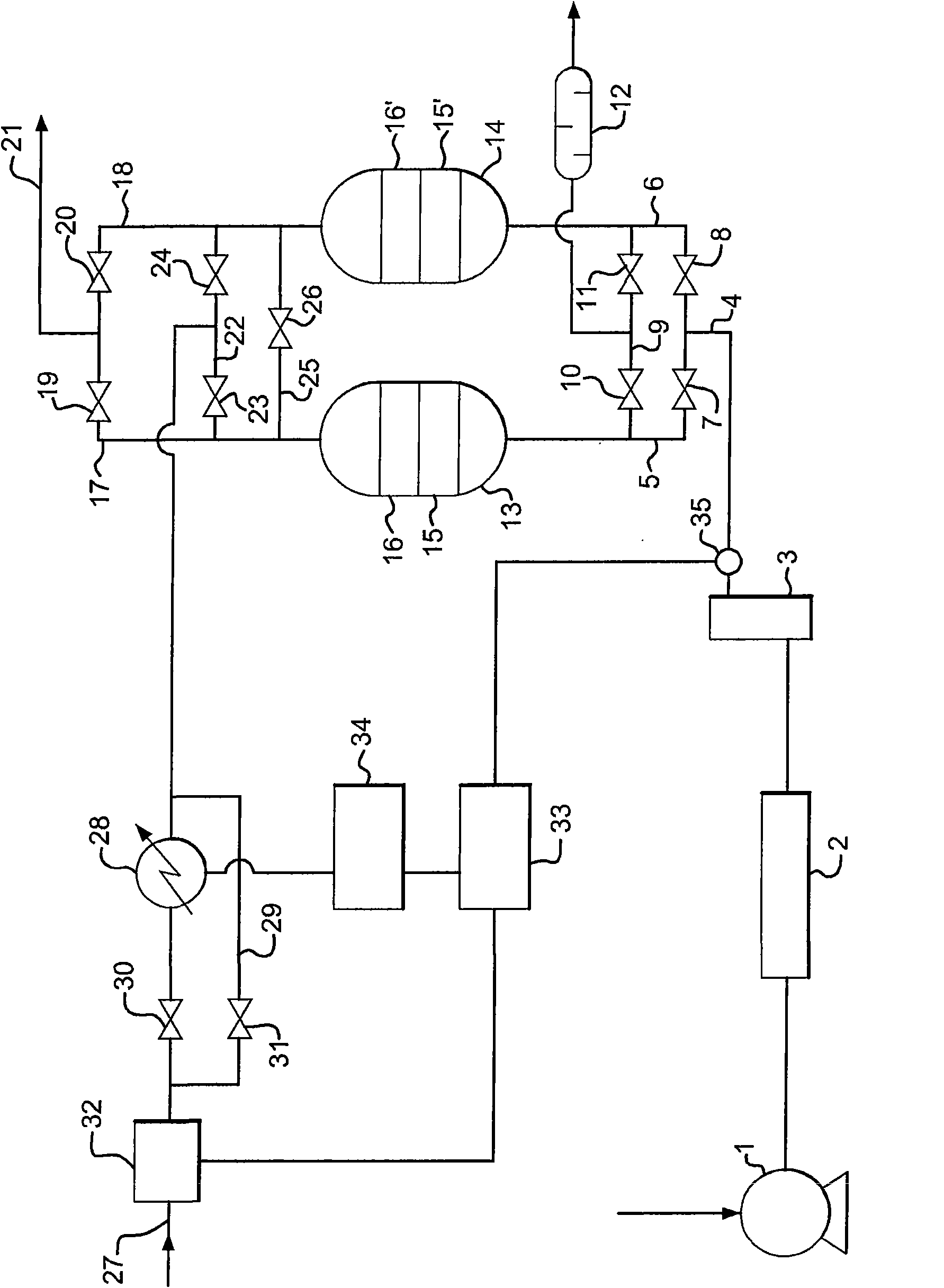

Method used

Image

Examples

Embodiment 1

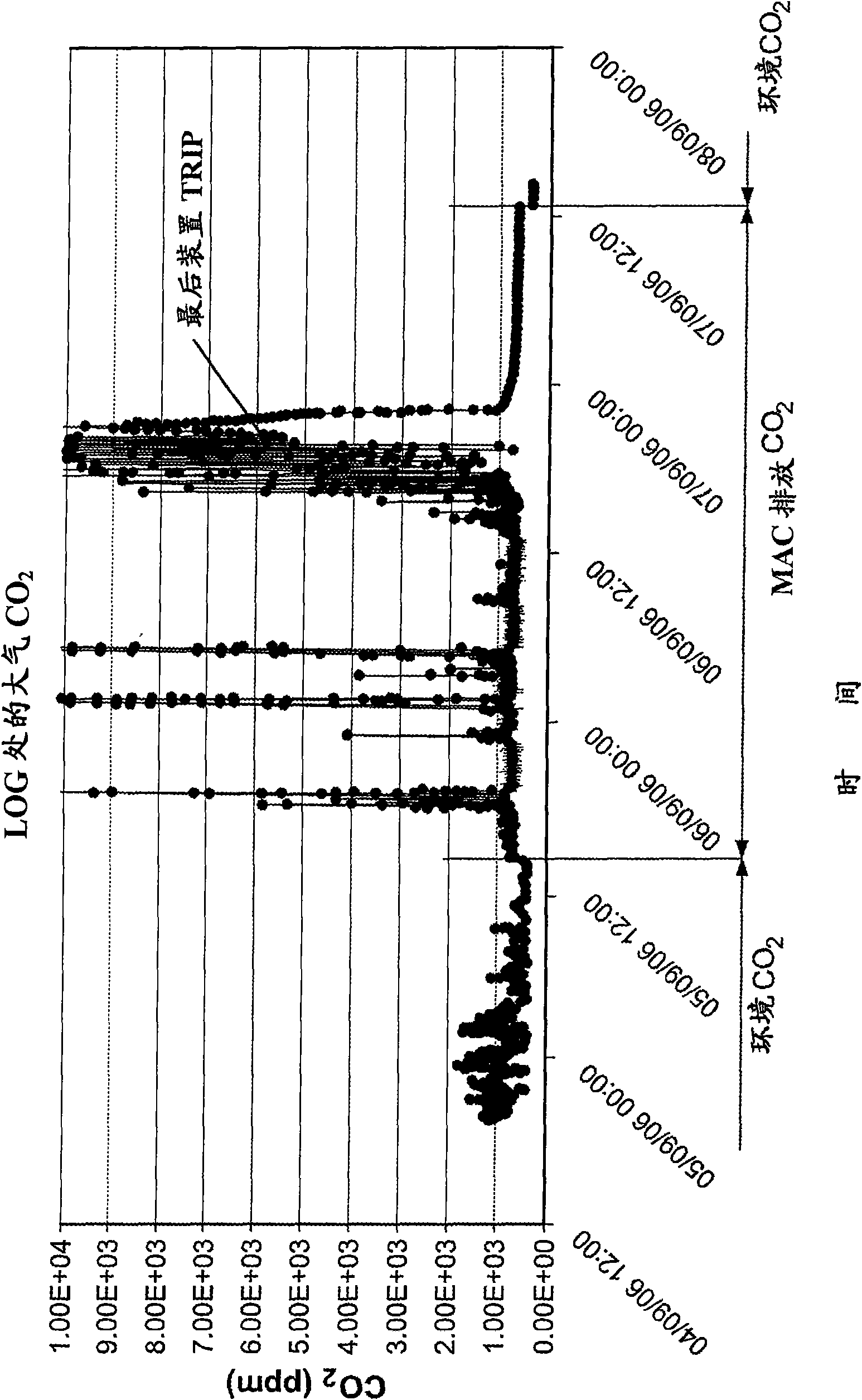

[0082] Example 1: TPSA cycle (as described in US Patent No. 5,855,650)

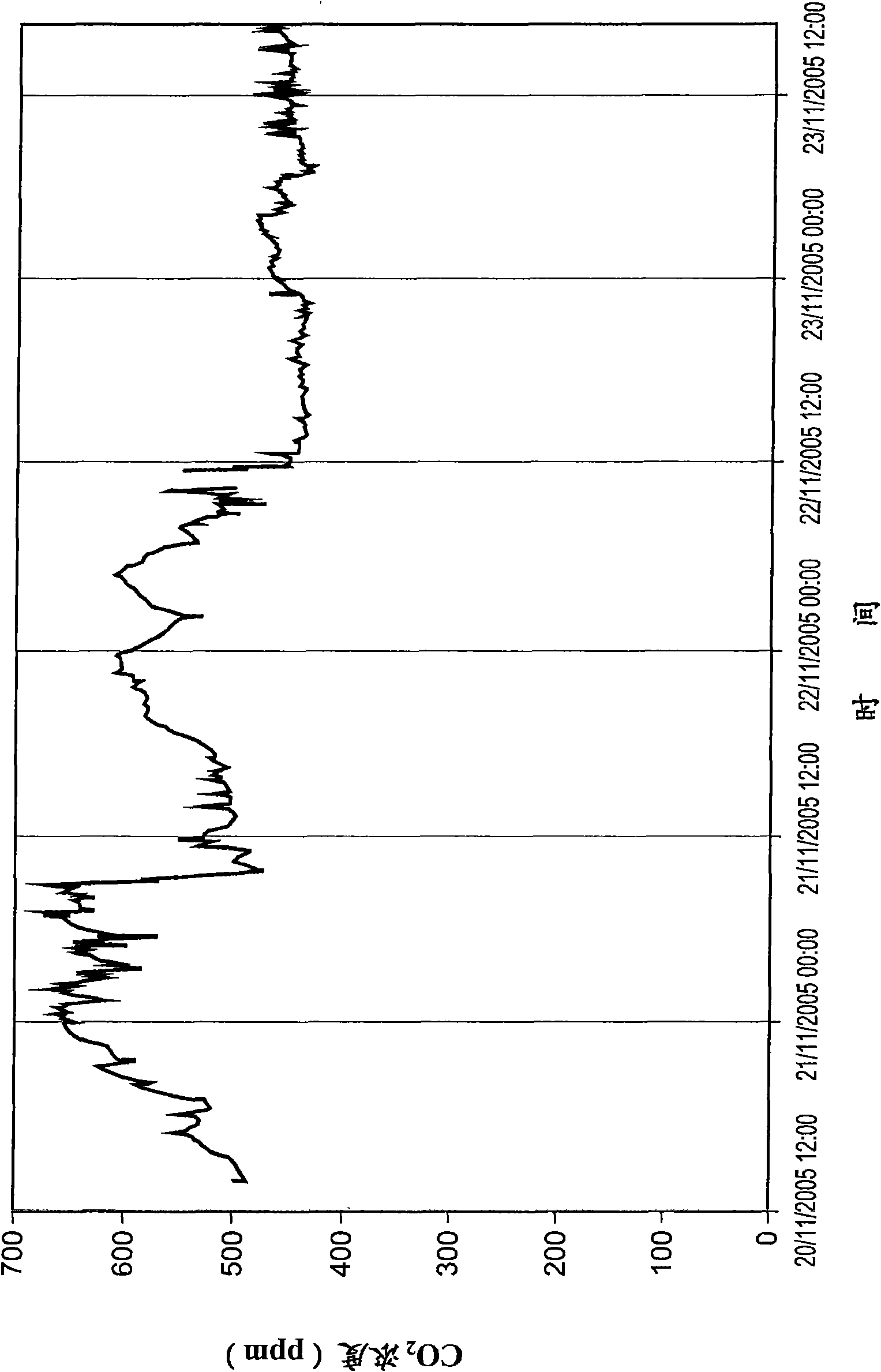

[0083] CO in raw materials 2 reduced ordinary

[0084] design example

[0085] Operation case

[0086] Container diameter (mm) 6000 6000

[0087] Container Tan-Tan length (mm) 3006 3006

[0088] Raw material temperature (°C) 18.3 18.3

[0089] Raw material pressure (MPa) 0.6 0.6

[0090] Raw material CO 2 (ppm) 1000 400

[0091] Raw water (ppm) 3602 3602

[0092] Total raw material flow rate (kmol / hr) 5928 5928

[0093] Running time (hr) 3.07 5

[0094] Regeneration time (hr) 2.57 4.5

[0095] Mass of alumina (kg) 26958 26958

[0096] Mass of 13X (kg) 22869 22869

[0097] Regeneration temperature (℃) 200 200

[0098] Required regeneration flow (kmol / hr) 1121 735

[0099] Pressure drop in feed step (kPa) 14.6 14.6

[0100] Pressure drop in regeneration step (kPa) 12.3 6.17

[0101] Compression power required to overcome pressure drop 321 229

[0102] (kW)

PUM

| Property | Measurement | Unit |

|---|---|---|

| composition ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com