Warping apparatus and warping shaft

A warping beam and equipment technology, applied in the field of textile weaving, can solve the problems of unable to warp normally and the number of packages is small, and achieve the effect of simple structure, reduced raw material cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

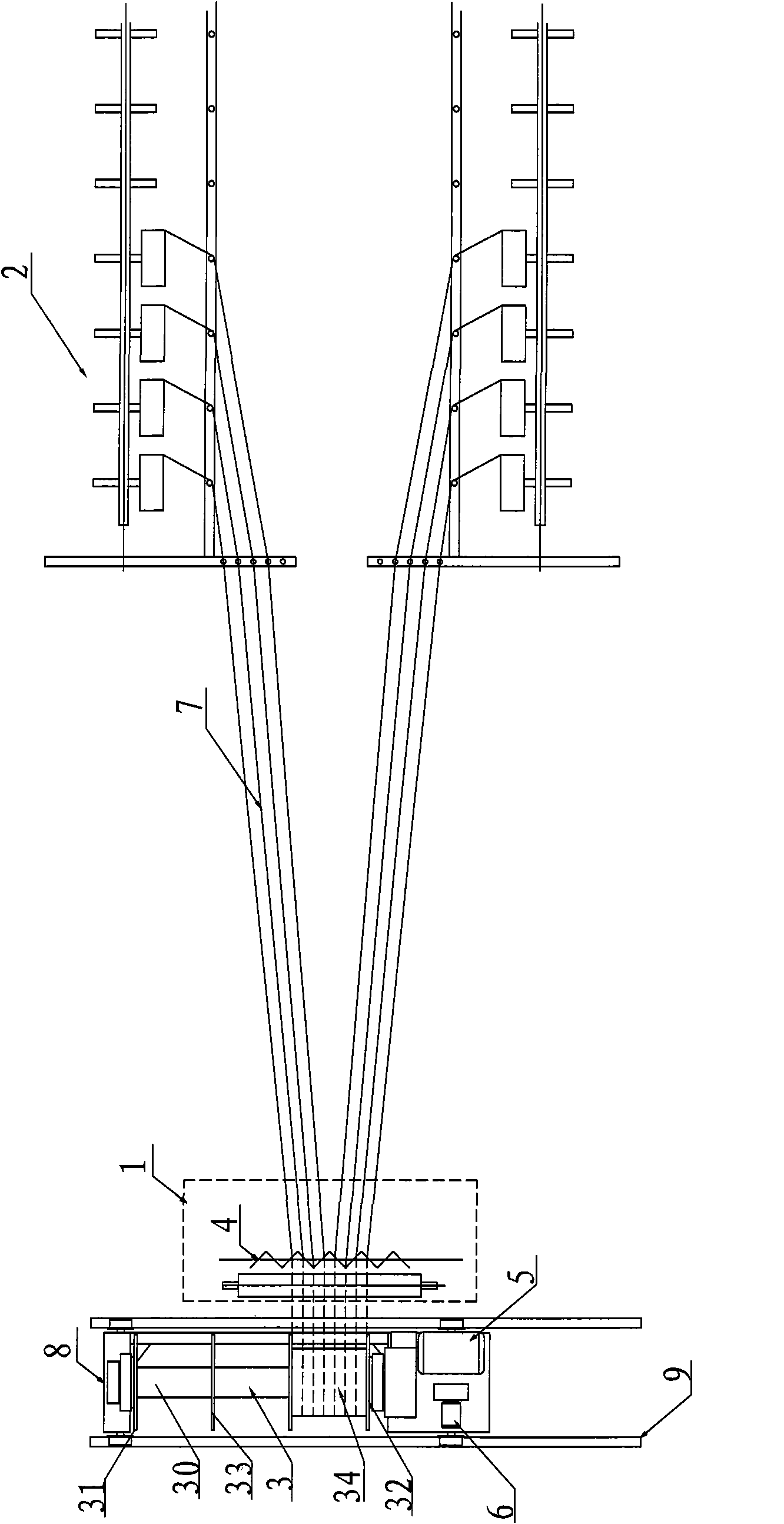

[0012] Such as figure 1 and 2 As shown, the warping equipment according to this embodiment mainly includes a frame 1, a creel 2, a telescopic reed 4 arranged on the frame 1, a warping beam 3 positioned in front of the telescopic reed 4, and a beam for driving the warping beam 3. The rotating first drive device 5 and the second drive device 6 for driving the warp beam 3 to move along its axis.

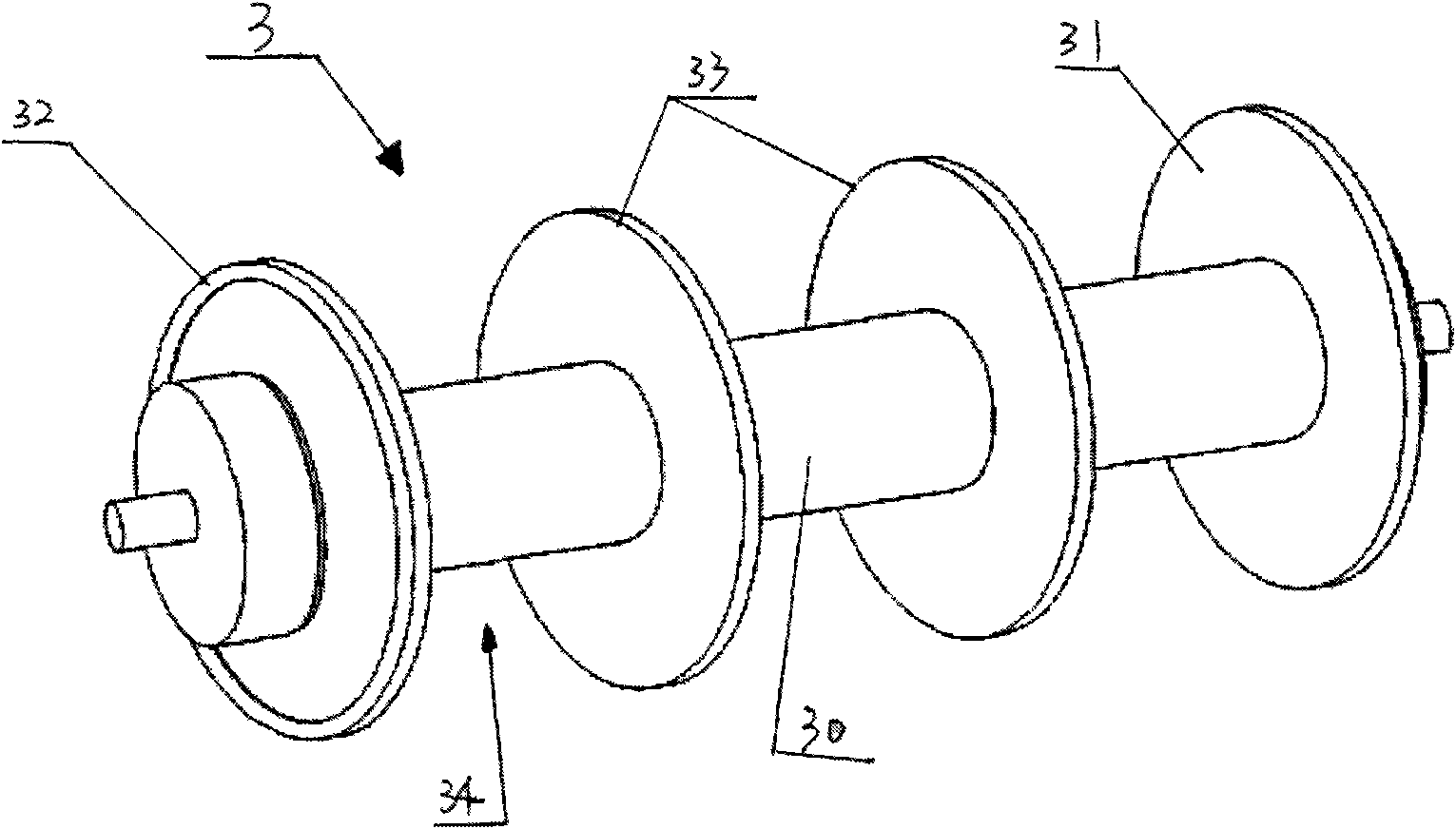

[0013] The warp beam 3 includes a shaft body 30 perpendicular to the advancing direction of the yarn 7, a first baffle plate 31 and a second baffle plate 32 respectively arranged at both ends of the shaft body 30, and a first baffle plate 31 and a second baffle plate 32 arranged on 2 partitions 33 between the second baffles 32, these 2 partitions divide the shaft body 30 into three warping sections 34 with equal width, of course, the number of partitions 33 can also be 1, 3 or more, the more the number of partitions 33, the more the number of warping sections 34, and the smaller the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com