Gas pressurized device

A technology of gas pressurization and pressurization cylinder, which is used in fluid pressure converters, mechanical equipment, etc., can solve the problems of poor sealing and lubrication conditions, waste of gas source, and high manufacturing cost, and achieves prevention of rigid collision, high output pressure, and high manufacturing cost. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

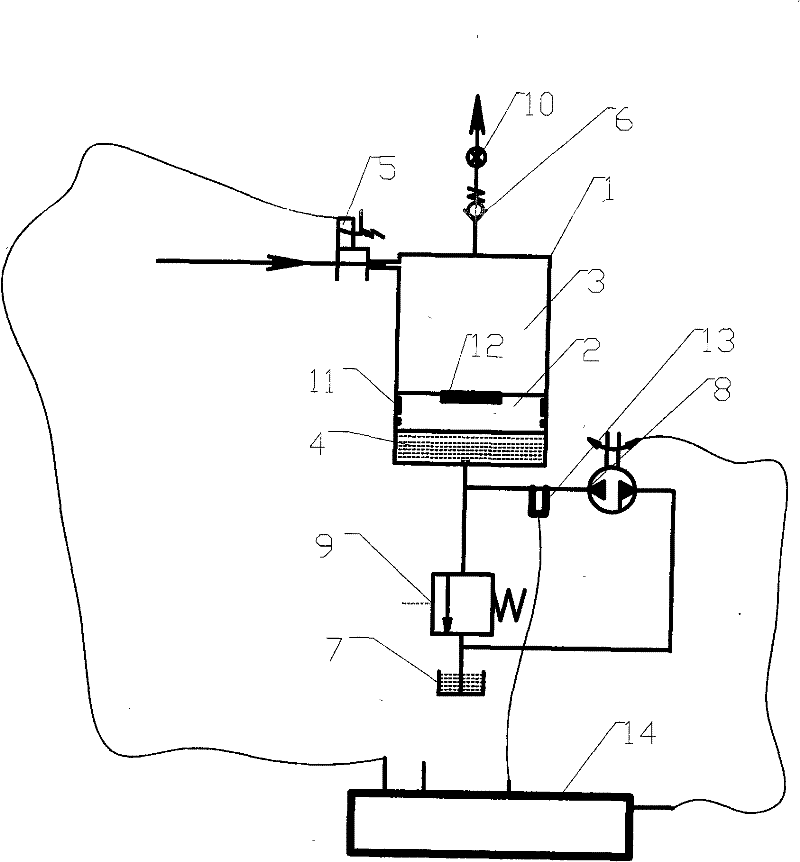

[0028] When the present invention is applied in an industrial high-pressure air supply with low requirements, it includes a booster cylinder 1, a floating piston 2 is arranged in the cylinder barrel of the booster cylinder 1, and the floating piston 2 divides the booster cylinder 1 into a booster chamber 3 and a The oil chamber 4 and the intake pipe of the pressurization chamber 3 are provided with an air intake valve 5, and the exhaust port on the upper end cover of the pressurization chamber 3 is provided with a check valve 6. The oil chamber 4 communicates with the fuel tank 7 through the oil pipe, and the oil pipe is provided with Two-way hydraulic oil pump 8 is arranged.

[0029] In the present invention, the oil pipe connecting the oil chamber 4 and the hydraulic oil pump 8 is provided with a pressure relief valve 9 installed in parallel with the hydraulic oil pump 8 . A pressure gauge 10 is installed at the outlet of the one-way valve 6 for monitoring the output pressur...

Embodiment 2

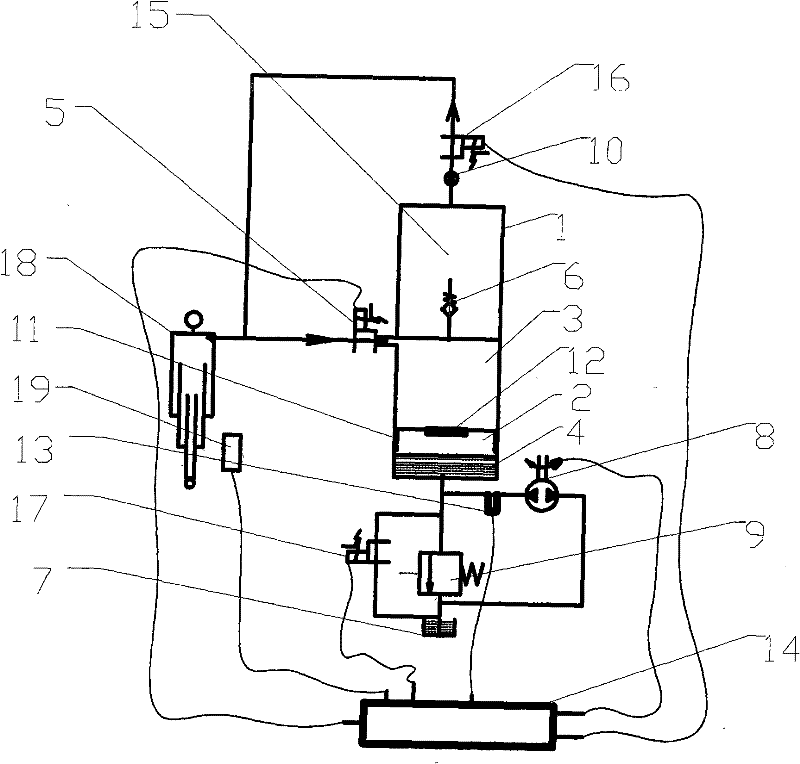

[0036] When the present invention is applied in a vehicle circulating air supply system or other circulating air systems, it includes a booster cylinder 1, a floating piston 2 is arranged in the cylinder barrel of the booster cylinder 1, and the floating piston 2 separates the booster cylinder 1 into booster cylinders. The chamber 3 and the oil chamber 4 are provided with an air intake valve 5 at the inlet of the booster chamber 3 and a check valve 6 at the outlet. The oil chamber 4 communicates with the oil tank 7 through the oil pipe, and the oil pipe is provided with a hydraulic oil pump 8 .

[0037]The present invention also includes a gas storage chamber 15, which communicates with the pressurization chamber 3 through the one-way valve 6. The gas storage chamber 15 is connected with an air delivery pipe, and an exhaust valve 16 and a pressure gauge 10 are arranged on the air delivery pipe. The air storage chamber 15 and the pressurization chamber 3 are integrated, and the...

Embodiment 3

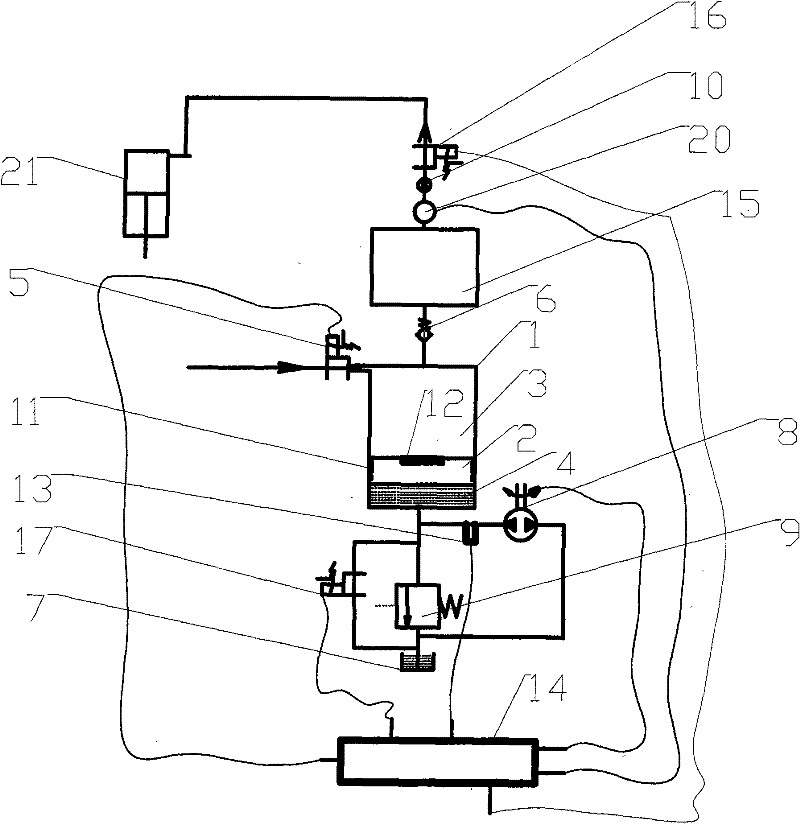

[0047] The present invention is applied to industrial high-pressure gas supply that requires stable gas supply pressure, including a booster cylinder 1, a floating piston 2 is arranged in the cylinder barrel of the booster cylinder 1, and the floating piston 2 divides the booster cylinder 1 into a booster chamber 3 And the oil chamber 4, the air intake of the booster chamber 3 is provided with an air intake valve 5, and the exhaust is provided with a check valve 6. The oil chamber 4 communicates with the oil tank 7 through the oil pipe, and the oil pipe is provided with a hydraulic oil pump 8.

[0048] The present invention also includes a gas storage chamber 15, which communicates with the pressurization chamber 3 through the one-way valve 6, the gas storage chamber 15 is connected with an air delivery pipe, and an exhaust valve 16 is arranged on the air delivery pipe. An exhaust pipe is connected between the air storage chamber 15 and the pressurization chamber 3, and the che...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com