Lighting device, electro-optic device, and electronic device

A lighting device and light source technology, which is applied in the direction of lighting devices, fixed lighting devices, lighting and heating equipment, etc., can solve the problems of temperature rise, difficulty in realizing thinning of backlight device, and reduction of light source luminous efficiency, so as to achieve thinning, Effects of easy replacement work and easy assembly work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0054] (Structure of liquid crystal device)

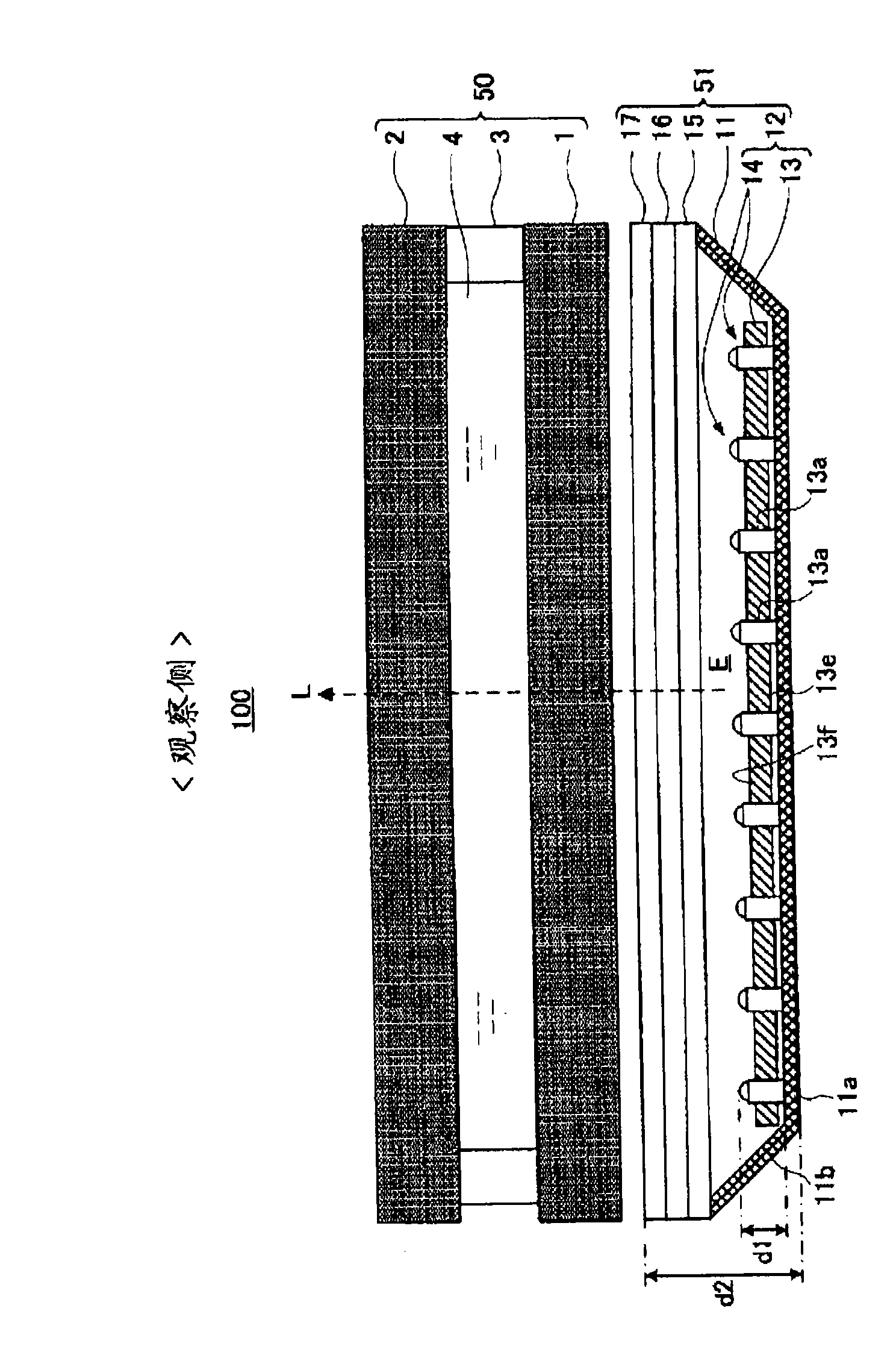

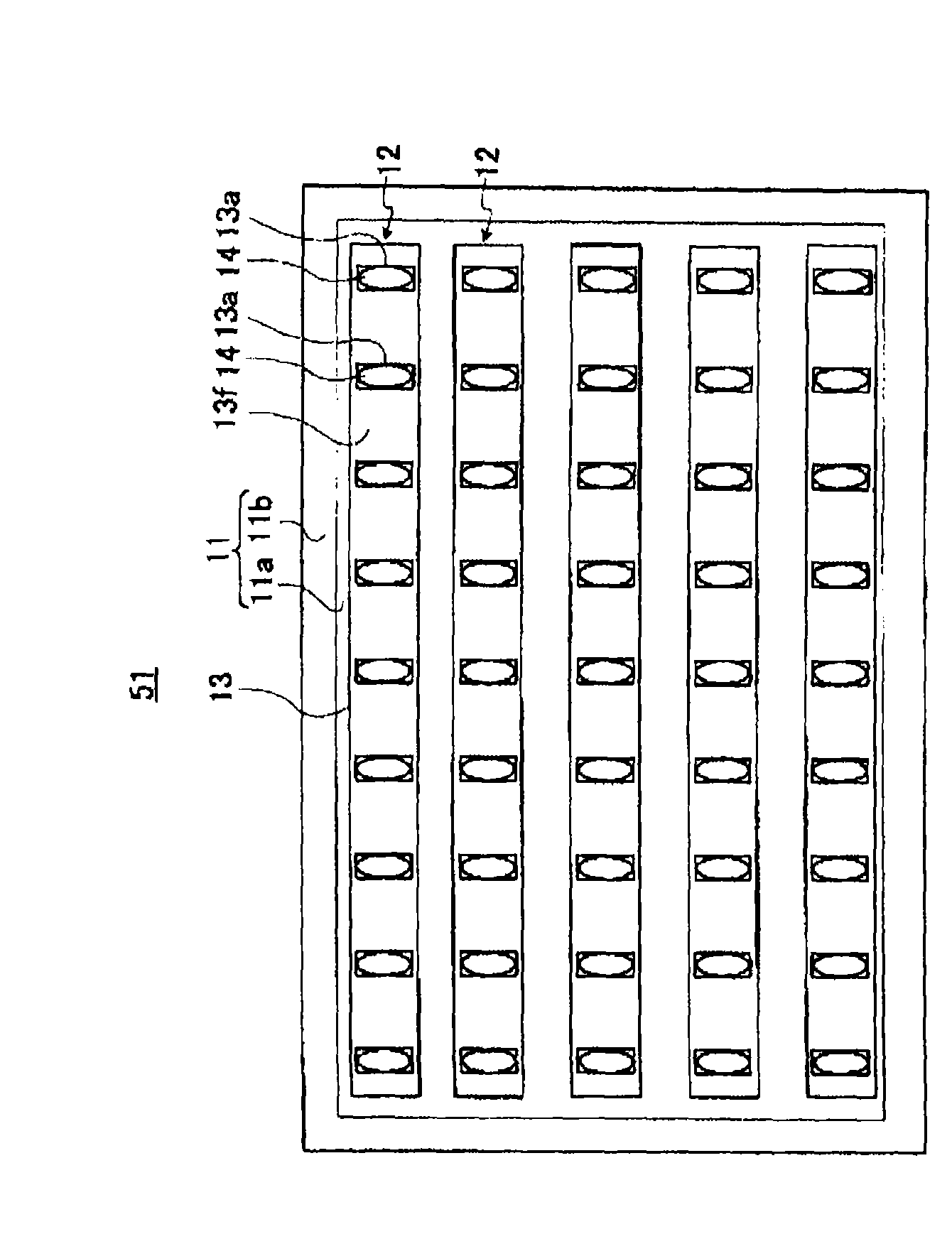

[0055] First, refer to Figure 1 to Figure 3 Next, the structure of the liquid crystal device 100 as an example of the electro-optical device according to the first embodiment of the present invention will be described.

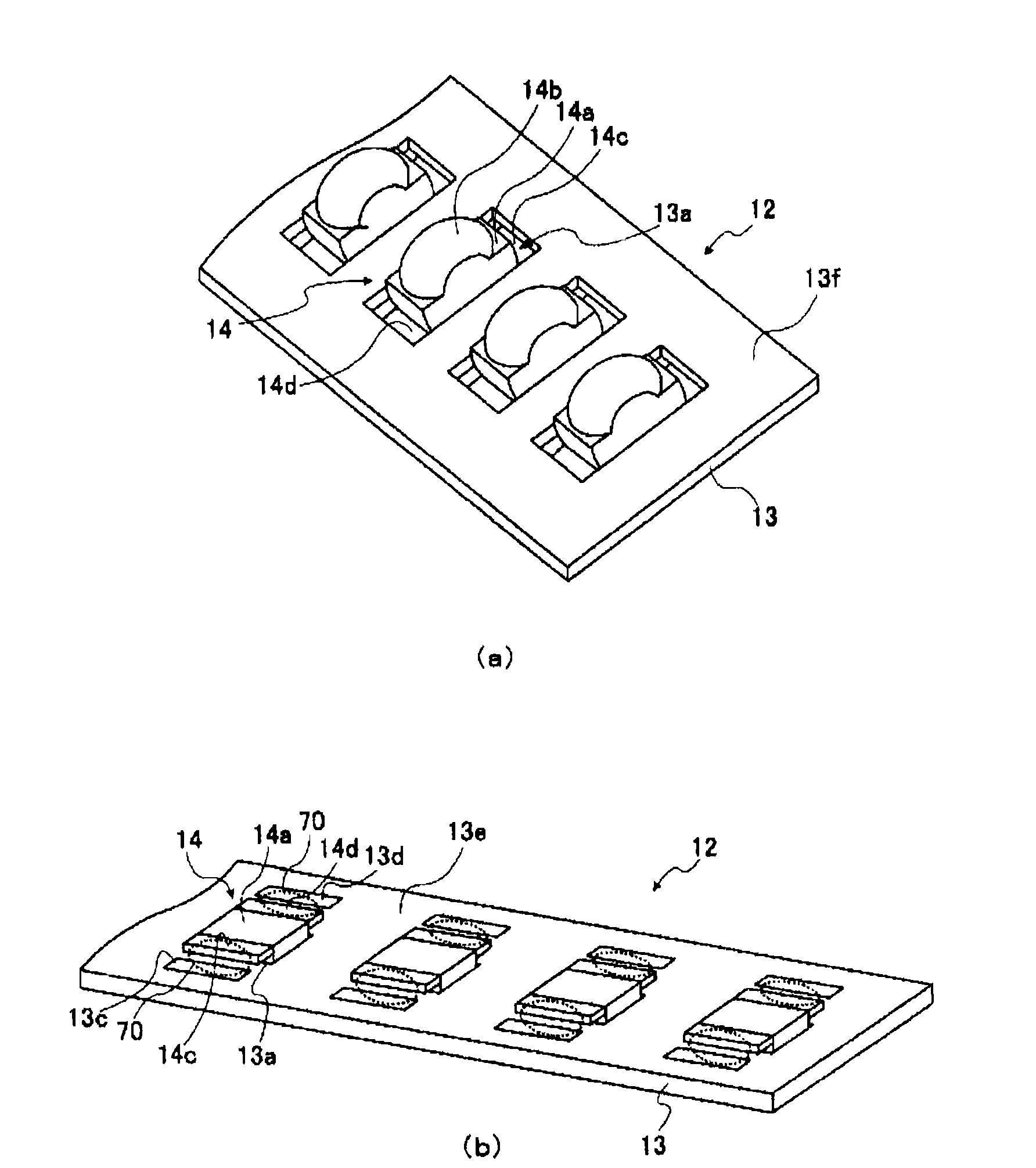

[0056] figure 1 It is a cross-sectional view showing a schematic configuration of the liquid crystal device 100 in the first embodiment. figure 2 means from figure 1 A plan view of the illuminating device 51 as a constituent element of the liquid crystal device 100 seen from the observation side (the side recognized by the observer) of . But when figure 2 In the figure, illustration of various optical sheets that are elements of the lighting device 51 is omitted for convenience. image 3 (a) is a perspective view showing main parts of the light source unit 12 seen from the light emitting side of the light source 14 . image 3 (b) shows a perspective view of main parts of the light source unit 12 seen from ...

no. 2 Embodiment approach

[0073] Below, refer to Figure 4 (a) and (b) demonstrate the structure of the liquid crystal device 100a provided with the illumination device 51a in 2nd Embodiment of this invention.

[0074] Figure 4 (a) is a sectional view which shows the schematic structure of the liquid crystal device 100a provided with the illumination device 51a of 2nd Embodiment. Figure 4 (b) is with image 3 (b) Correspondingly, a perspective view of main parts of the lighting device 51a showing the arrangement relationship between the heat dissipation member 18 and the light source unit 12 in the second embodiment.

[0075] When comparing the second embodiment with the first embodiment, in the second embodiment, a heat dissipation member for dissipating the heat generated by the light source 14 is provided in the lighting device 51a. are different, but otherwise the structure is the same. Therefore, hereinafter, the same reference numerals are assigned to the same elements as those in the first...

no. 3 Embodiment approach

[0081] Below, refer to Figure 5 and Figure 6 The structure of the liquid crystal device provided with the illumination device 51b in 3rd Embodiment of this invention is demonstrated.

[0082] Figure 5 It shows the top view of the illuminating device 51b in 3rd Embodiment seen from the observation side. But when Figure 5 In the figure, illustration of various optical sheets that are elements of the lighting device 51b is omitted for convenience.

[0083] Figure 6 (a) is a perspective view showing main parts of the circuit board 13x constituting the light source unit 12x in the third embodiment. Figure 6 (b) shows a perspective view of main parts of the light source unit 12x seen from the light emission side of the light source 14. FIG. Figure 6 (c) shows a plan view of main parts of the light source unit 12x seen from the side opposite to the light emitting side of the light source 14 .

[0084] When comparing the liquid crystal device in the third embodiment with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com