Refrigerator self detection method

A technology for refrigerators and detection ports, which is applied in the field of self-inspection of refrigerators, can solve problems such as troublesome, self-inspection is not allowed, and achieve the effect of simple and feasible method and intuitive fault detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

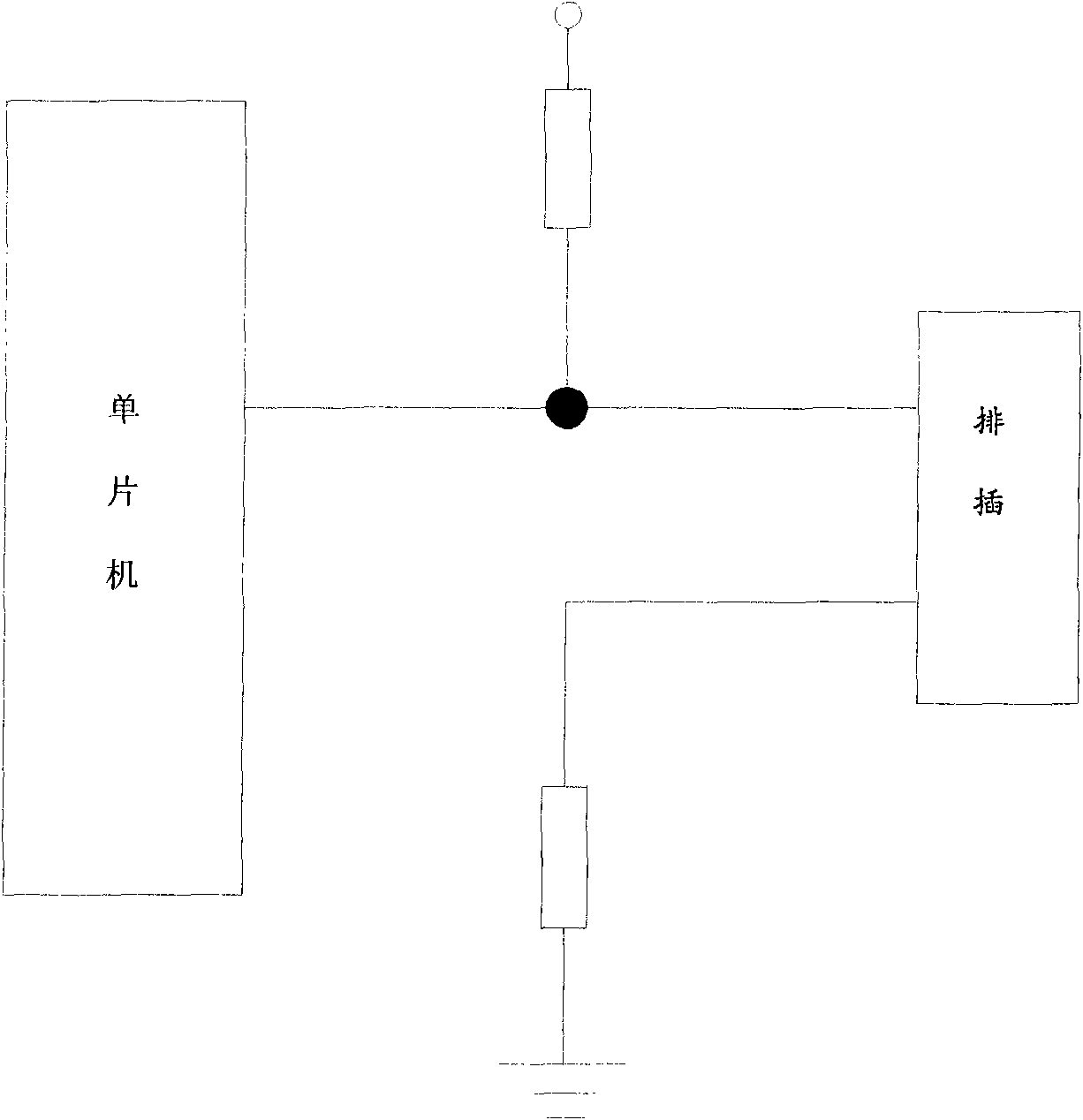

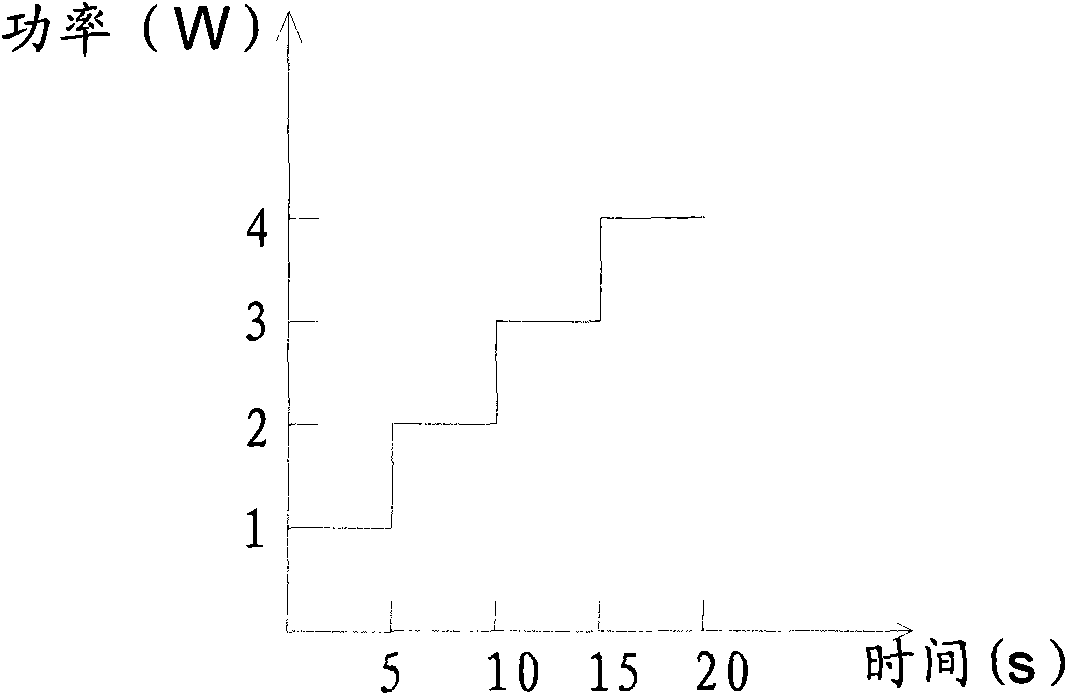

[0014] Refrigerator self-checking method of the present invention is such, as figure 1 As shown, a general refrigerator includes a CPU, a power supply, and the connection between the power supply and the CPU. It is characterized in that: the refrigerator also includes a detection port, and the detection port is set as a socket connected to the CPU. The power supply of the refrigerator is connected to the power detector. During the initial power-on, the level status of the input port, if the input is high, set the refrigerator to be in normal working state; if the input is low, set the refrigerator to be in the self-test state, and then add a short circuit on the row Plug in, the CPU input pin becomes low level, enters the self-test program, and then connects each power component sequentially, and observes whether the curve of the power detector shows a power curve consistent with the power component. If the power curve does not change, the power component If it is damaged, rep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com