Process and apparatus for producing clathrate hydrate slurry and method of operating the production apparatus

A technology for clathrate hydrate and hydrate slurry, which is used in the manufacture of ice, chemical instruments and methods, and ice making, etc., can solve the problems of inability to manufacture clathrate hydrate slurries stably for a long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

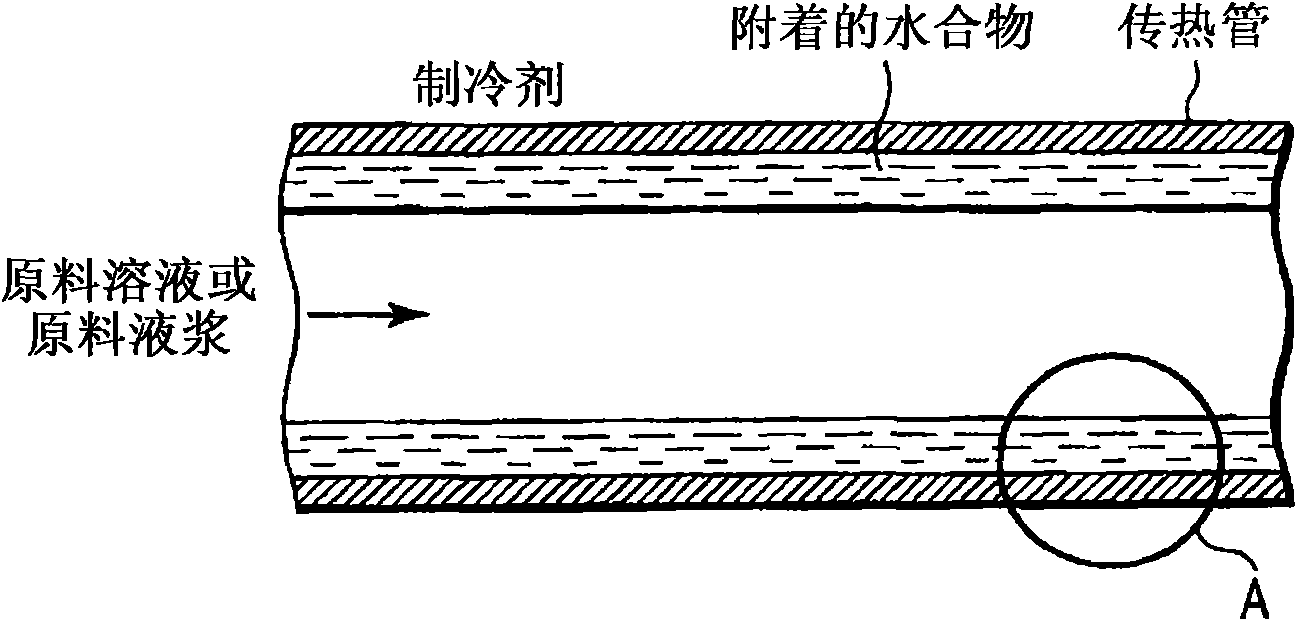

[0268] Figure 16 It is an explanatory drawing explaining the structure of the manufacturing apparatus of the clathrate hydrate slurry which concerns on one Embodiment of this invention.

[0269] The clathrate hydrate slurry manufacturing apparatus according to this embodiment includes: a heat exchanger 1 for exchanging heat between a raw material solution (an aqueous solution of a guest compound that forms a hydrate) or a raw material slurry and a refrigerant; a refrigerant supply device 21, which supplies refrigerant to the heat exchanger 1; the heat storage tank 5, which stores the raw material solution or raw material slurry and the generated hydrate slurry; the input side flow path 8, one end of which communicates with the heat storage tank 5, and the other end It communicates with the input side of the heat exchanger 1; the output side flow path 9 communicates with the output side of the heat exchanger 1 at one end and communicates with the heat storage tank 5 at the oth...

Embodiment 1

[0326] [Heat storage air conditioning system 1]

[0327] In the heat storage air conditioning system 1 according to Embodiment 1, the refrigerator for slurry production is operated at night to store heat, and the stored heat is released during the day to perform cooling operation. When the cooling load is high during the day, the slurry production The refrigerator operates to store heat while performing cooling and cooling operation. It has the feature that even when the cooling load is high during the daytime, it can be handled by one refrigerator for slurry production.

[0328] Figure 18 It is an explanatory drawing of the equipment structure of Example 1, and shows the equipment structure when it is applied to the building whose maximum cooling load corresponds to 400RT.

[0329] The heat storage air-conditioning system 1 involved in Embodiment 1 has: a refrigerator 81 for slurry production, which produces hydrate slurry; a heat storage pump 82, which is installed on the...

Embodiment 2

[0345] [Heat storage air conditioning system 2]

[0346] The heat-storage air-conditioning system 2 according to the second embodiment is based on storing heat by operating the freezer for slurry production at night, and performing cooling operation in which heat is released and stored during the day, and can be used when the cooling load is high during the day. It is supplemented by cold water produced by other chillers.

[0347] Figure 19 is an explanatory diagram of the device structure of the present embodiment 2, and Figure 18 The same parts are denoted by the same reference numerals. Such as Figure 19 Shown, in this embodiment 2, in Figure 18 In addition to the structure shown, the chiller 91 for cold water which produces 7 degreeC cold water, and the primary pump 92 for cold water which send cold water from the chiller 91 for cold water are added.

[0348] The heat storage operation at night and the cooling operation using heat storage during the day were perfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com