Solenoid valves, throttling devices and refrigeration units

A technology for solenoid valves and throttling parts, applied in the field of solenoid valves, can solve the problems of limited axial height of the sound-absorbing part 23, unsatisfactory sound-absorbing effect, weakened sound-absorbing effect, etc., to improve reliability and service life, and absorb refrigerant flow noise , The effect of simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

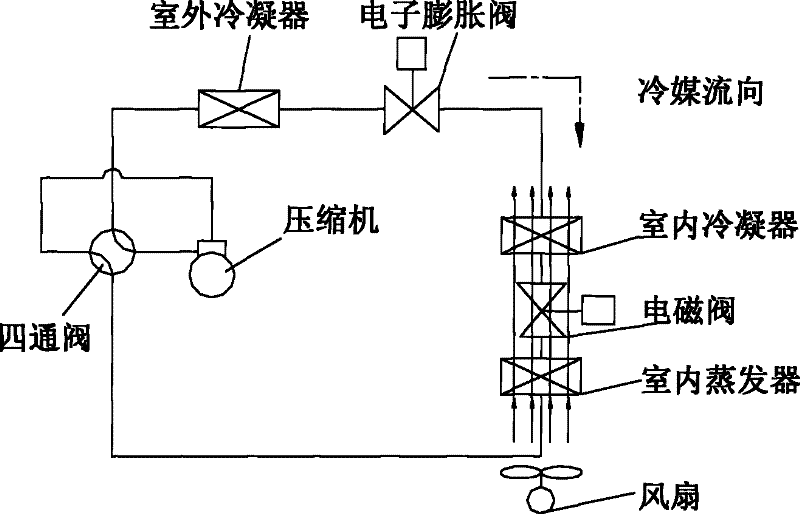

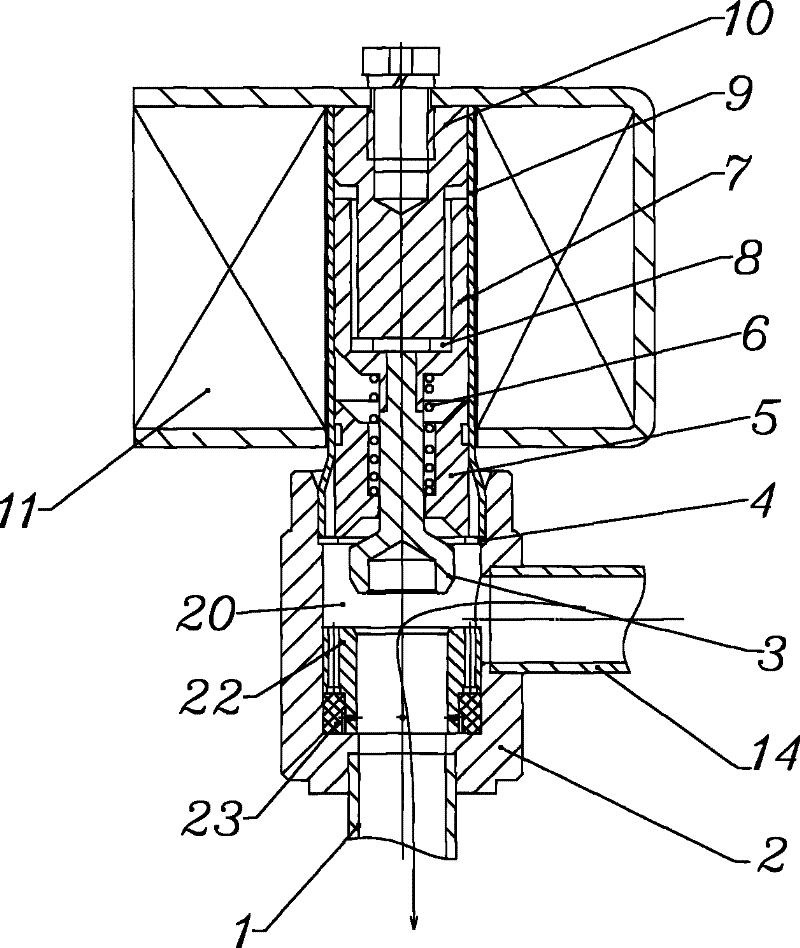

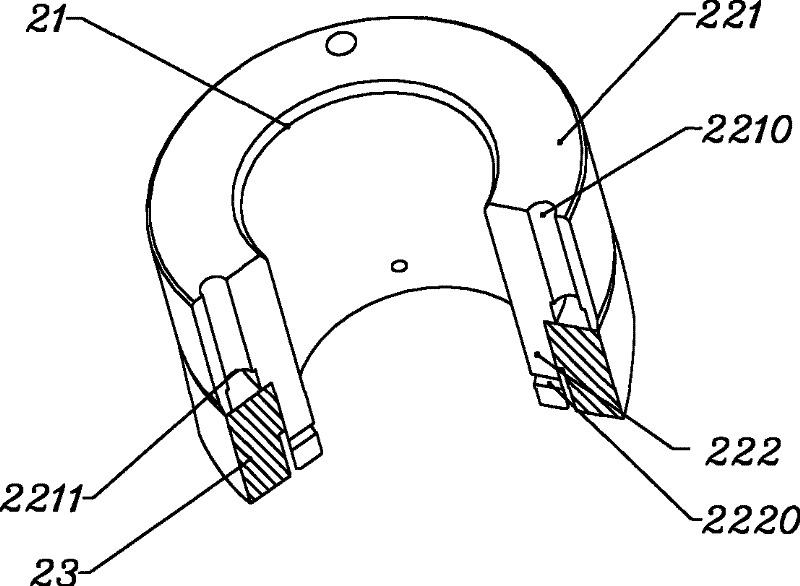

[0055] Figure 4 It is a structural schematic diagram of the solenoid valve in the open state of the embodiment, Figure 5 It is a structural schematic diagram of the solenoid valve in the closed state of the embodiment, Figure 6 is a structural schematic diagram of the throttling part in the solenoid valve, Figure 7 is a structural schematic diagram of the sound-absorbing component in the solenoid valve, Figure 8 is a schematic diagram of the assembled structure of the throttling component and the sound-absorbing component, Figure 9 yes Figure 8 Sectional view of the middle throttle and sound-absorbing components.

[0056] Such as Figure 4 As shown, the solenoid valve includes: a valve seat 2; an inlet pipe 14 and an outlet pipe 1 fixed by the valve seat 2, and the inlet pipe 14 and the outlet pipe 1 are communicated by the inner chamber 20 of the valve seat; The inner cavity 20 is provided with a throttling part 12 and a sealing head 3; a casing 9 connected to th...

Embodiment 2

[0070] The difference between the electromagnetic valve in this embodiment and the first embodiment is that the shape of the groove of the throttling part and the cross-section of the sound-absorbing part are triangular or arc-shaped, and the structure and action principle of other parts are similar to those of the first embodiment. , which will not be repeated below.

[0071] Figure 10It is a cross-sectional view of the assembly structure of the throttling member and the sound-absorbing member described in this embodiment. The throttling member 12' is provided with a groove 123' spirally surrounding the outer surface of its side wall and recessed inward from the outer surface, the first end 123a' of the groove communicates with the inner cavity of the valve seat , the second end 123b' of the groove communicates with the main passage through the throttling passage 122' arranged on the side wall, and the sound-absorbing component 13' closely matched with it is embedded in the...

Embodiment 3

[0076] Figure 12 It is a schematic diagram of the assembly structure of the throttling component and the sound-absorbing component described in this embodiment. The difference from Embodiment 1 and Embodiment 2 is that the groove in this embodiment surrounds the side wall of the throttling component for two and a half weeks, and the structure and action principle of other parts are similar to those in Embodiment 1, and will not be repeated below.

[0077] Such as Figure 12 As shown, the throttling part 12'" is provided with a groove 123'" spirally surrounding its side wall, and a sound-absorbing part 13'" matched with it is embedded in the groove 123'", and the sound-absorbing part 13 The first end 13a'" of '" is located at the first end 123a'" of the groove, and the second end 13b'" of the sound-absorbing component is located at the second end 123b'" of the groove; the groove 123'" from the first end 123a'" to the second end 123b'" totally surrounds the side wall of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com