Lens module

A lens module and lens technology, applied in the direction of instruments, installation, optics, etc., can solve the problems of polluting image quality, long focusing time, short and short lens module height, etc., to avoid long-term focusing and reduce module height , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with illustrations and specific embodiments.

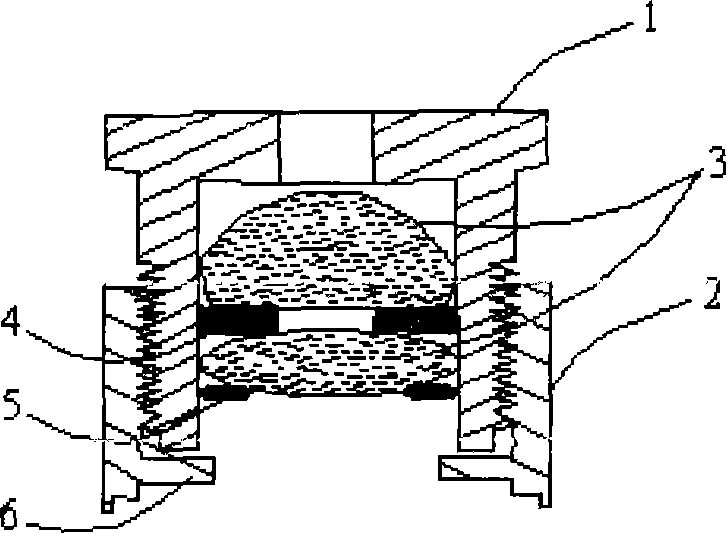

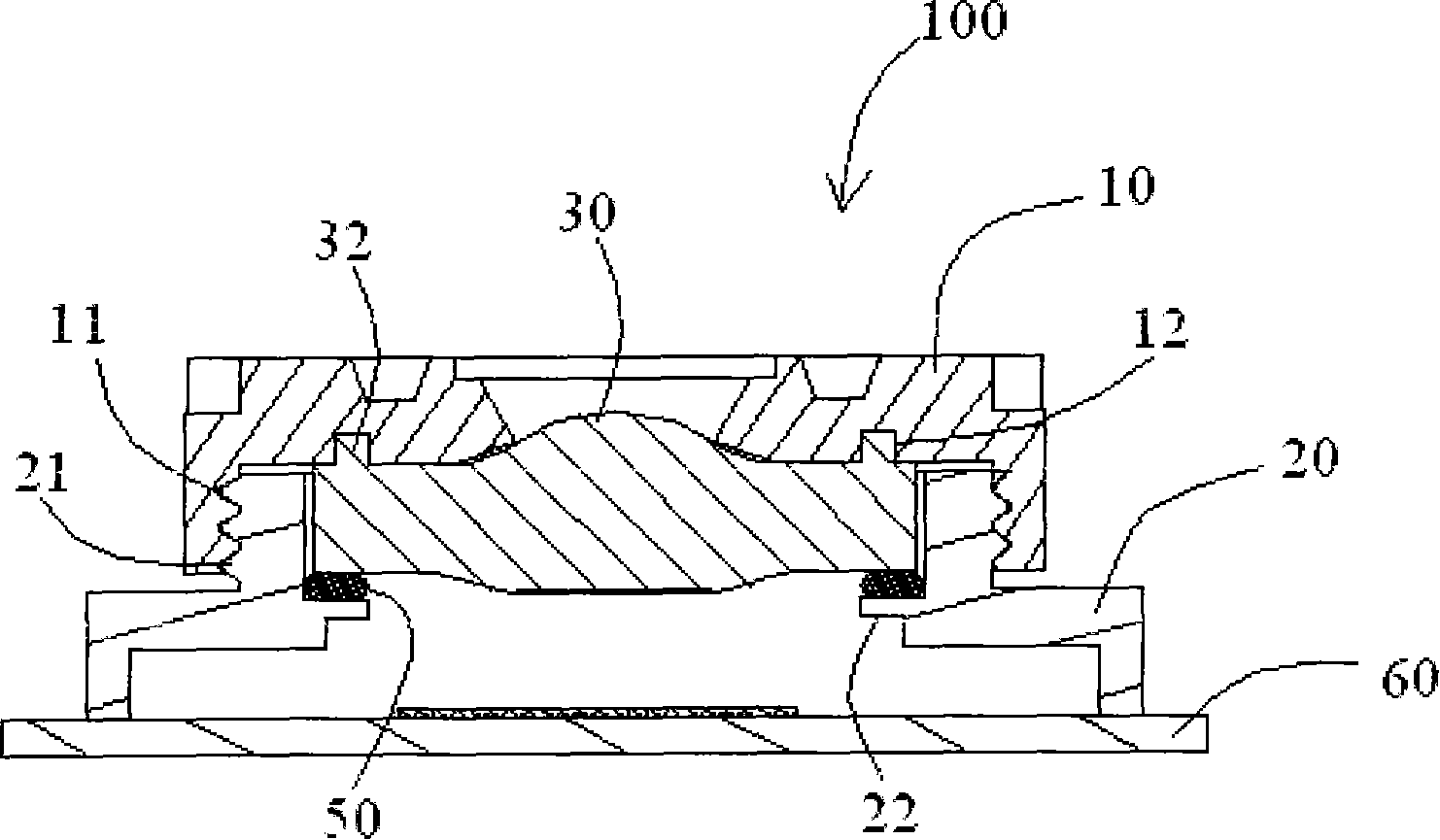

[0027] see image 3 , a structural diagram of the first embodiment of the present invention, the lens module 100 includes a lens barrel 10 , a lens holder 20 , a lens 30 , a sealing ring 50 , and an image sensor module 60 . Wherein, the lens barrel 10 has a bottom surface and a peripheral side wall to form a hollow cavity. A groove 12 is formed on the bottom surface, and an internal thread 11 is formed on the inner side of the peripheral sidewall. A protrusion 32 is disposed on the top of the lens 30 . The protrusion 32 is inserted into the groove 12 to fit together, so that the lens 30 is fixed in the hollow cavity of the lens barrel 10 . Preferably, an appropriate amount of glue can also be applied to make the lens 30 more stable.

[0028] The mirror base 20 has a peripheral sidewall, the outer sidewall of the peripheral sidewall is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com