Winding method for vertical winding machine for transformer coil

A vertical winding machine and transformer coil technology, which is applied to the winding of transformer coils and the field of transformers, can solve problems such as work obstacles, shortages, and poor personnel utilization, and achieve the effects of low price, low partial discharge, and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

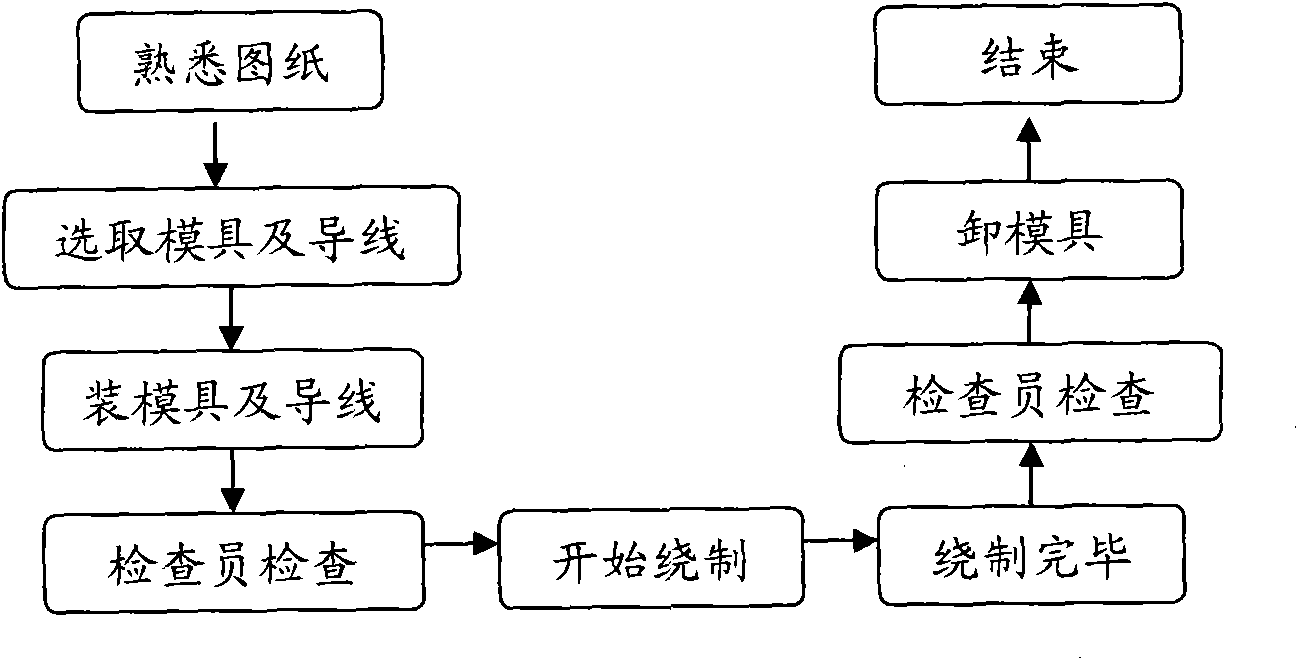

[0023] see figure 1 As shown, the vertical winding machine winding method of the transformer coil includes the following steps:

[0024] (1) Determine the outer circle size of the mold according to the drawing requirements;

[0025] (2) Assemble the winding mold of the vertical winding machine according to the size required by the drawing;

[0026] (3) Place wires;

[0027] (4) Start winding the transformer coil, and wind it to the specified number of turns according to the requirements of the drawing;

[0028] (5) After the coil is wound, hoist the coil and the mold to the pre-installation area together;

[0029] (6) Loosen the wire and remove the winding mold;

[0030] (7) Tighten the wire, and the winding is completed.

[0031] In actual use, the winding process of the present invention is mainly different from the prior art in that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com