Method for preparing catelectrode material LnA'CuO with K2NiF4 structure by electrostatic spinning

An electrospinning, cathode material technology, applied in battery electrodes, structural parts, circuits, etc., can solve the problems of poor electrode performance and poor chemical stability of cathode materials, and achieve low polarization resistance and good thermal shock resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

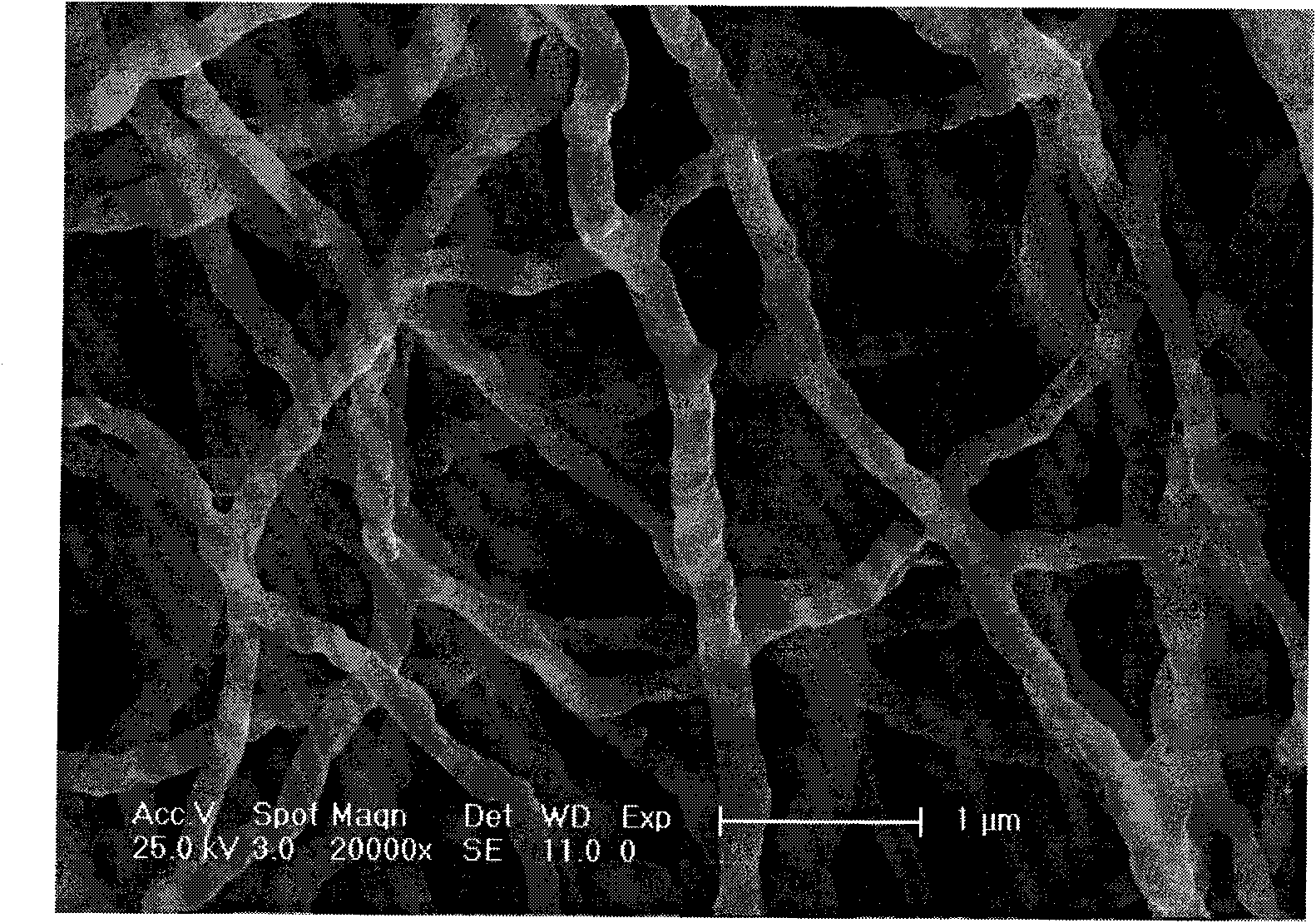

[0008] Specific implementation mode 1: In this implementation mode, electrospinning method is used to prepare 2 NiF 4 Structural battery cathode material Ln 2-x A' x CuO 4±δ The method is as follows: 1. After dissolving polyvinylpyrrolidone in ethanol, stir it at a speed of 30-80 rpm for 6h-8h under sealed conditions, and then let it stand at room temperature for 6h-12h to obtain a mass concentration of 8 %~15% polyvinylpyrrolidone ethanol solution; 2. According to the chemical formula Ln 2-x A' x CuO 4±δ According to the molar ratio of Ln element, A' element, Cu element and O element (2-x):x:1:(4±δ) ratio, respectively weigh Ln(NO 3 ) 3 , A'(CH 3 COO) 2 and Cu(CH 3 COO) 2, and then dissolved in distilled water to obtain a uniform and transparent system 1, where Ln 2-x A' x CuO 4±δ The mass percentage in system 1 is 8% to 20%, the Ln element is a rare earth element, the A' element is an alkaline earth metal element, and the chemical formula is Ln 2-x A' x CuO ...

specific Embodiment approach 2

[0010] Embodiment 2: This embodiment differs from Embodiment 1 in that the mass concentration of the polyvinylpyrrolidone ethanol solution described in step 1 is 9% to 13%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0011] Embodiment 3: This embodiment differs from Embodiment 1 in that the mass concentration of the polyvinylpyrrolidone ethanol solution described in step 1 is 10%. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com