Clay bar vertical splitter

A strip cutter and mud strip technology, which is applied in the field of construction machinery, can solve the problems of non-vertical cutting sections, waste of mud strips, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

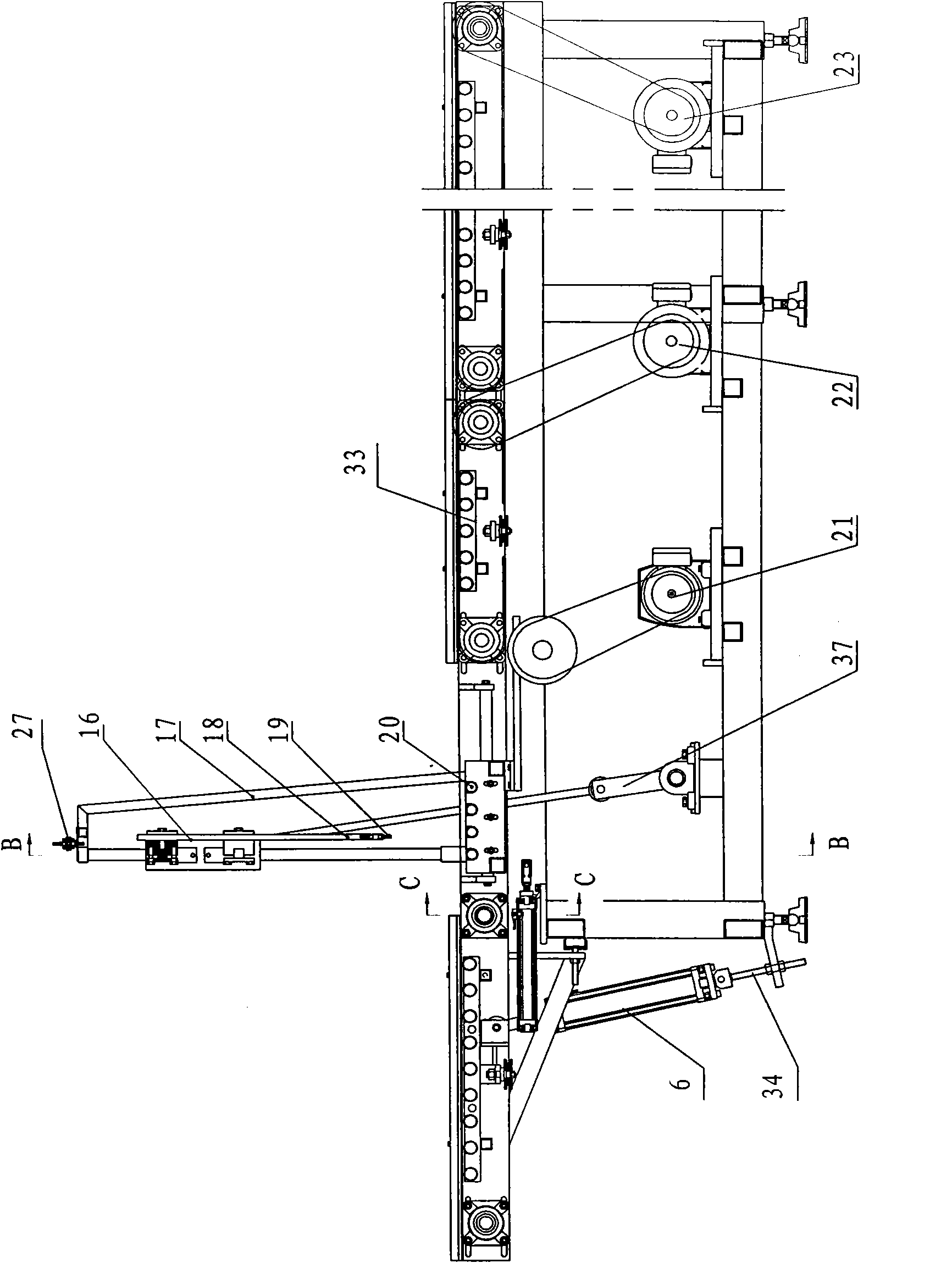

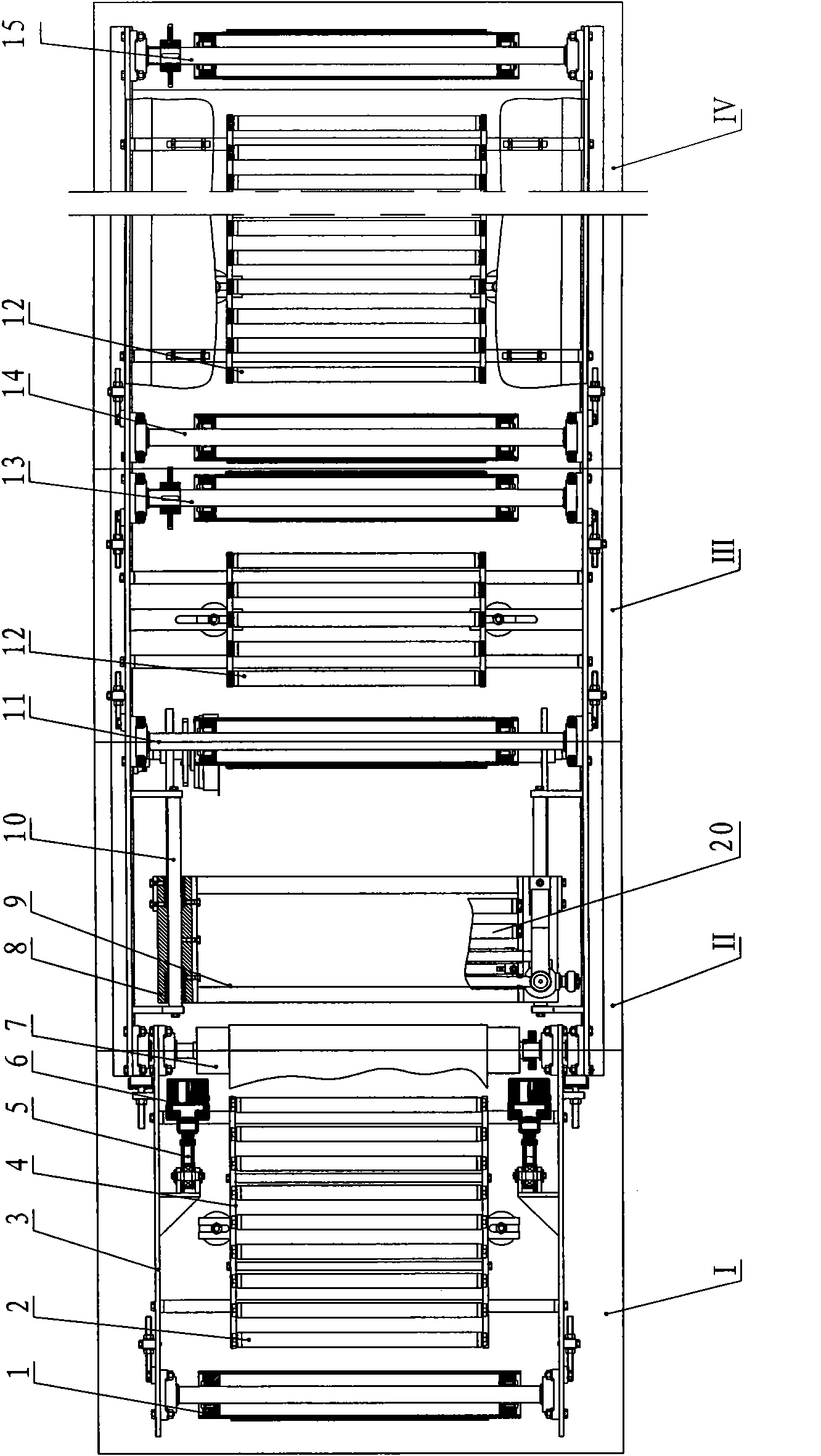

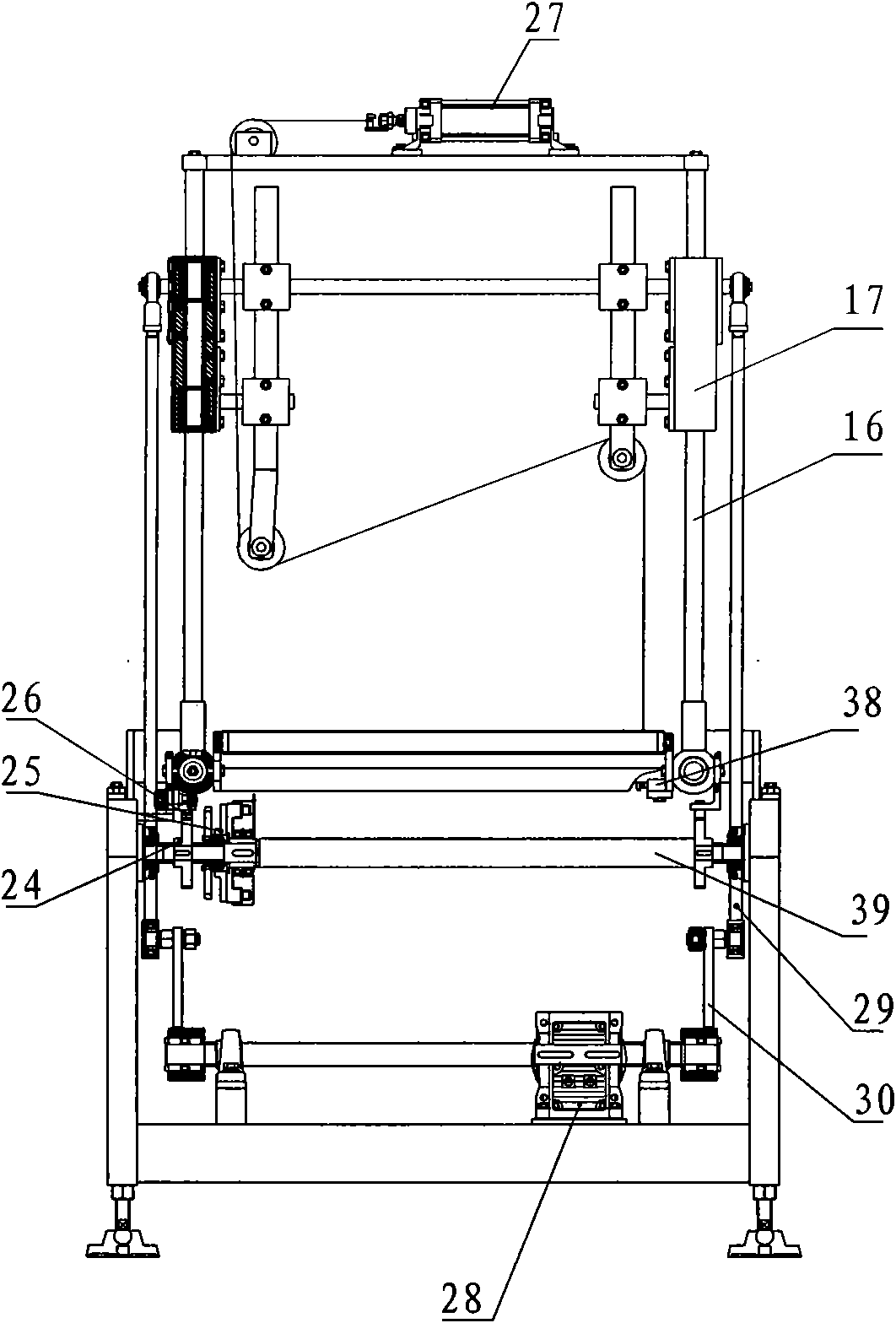

[0015] With reference to the accompanying drawings, the vertical strip cutting machine for mud strips includes a frame 32, and along the longitudinal direction of the frame, there are successively provided with a pre-strip strip transporting belt I, a cutting device II, a first strip-slitting post-strip transporting strip III and a second post-strip strip transporting belt III. Transport blank belt IV. The blank belt 1 before the first strip cutting is supported by a pair of rollers (1, 7), and the two rollers (1, 7) are installed on the frame 32 through the support 3, and idlers are installed between the two rollers through the roller bracket 4 2. There is an endless belt between the two rollers, and the idler 2 plays a supporting role in the endless belt. An encoder 31 connected to the control center signal is installed on the latter roller shaft, and a driven roller is installed on the roller shaft. Gear 36, encoder 31 has encoder gear 35 meshing with driven gear 36, cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com