Automatic setting machine

A blank stacker and automatic technology, applied in the direction of manipulator, object stacking, object unstacking, etc., can solve the problems of low production efficiency, unstable operation, and inaccurate positioning of chuck rotation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

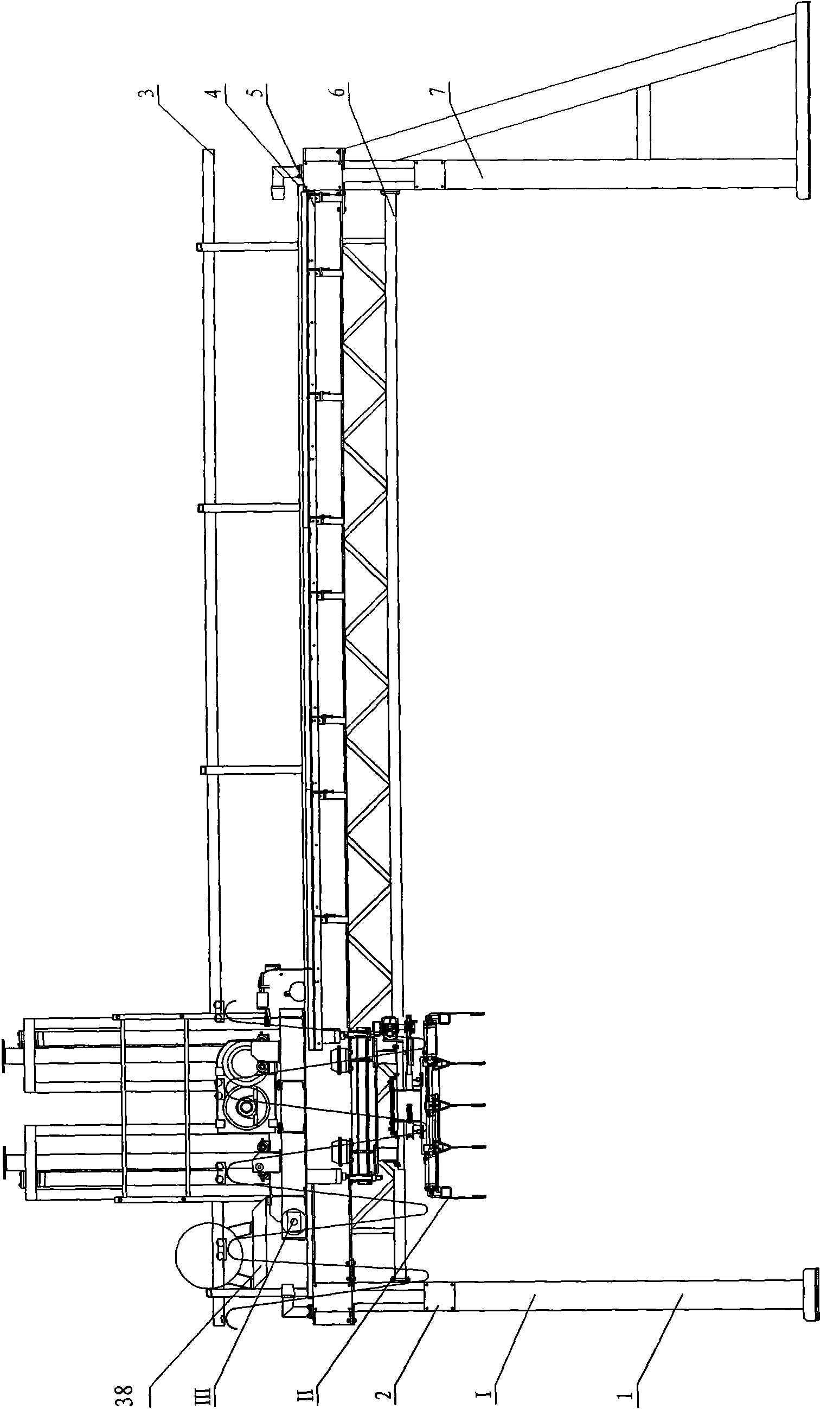

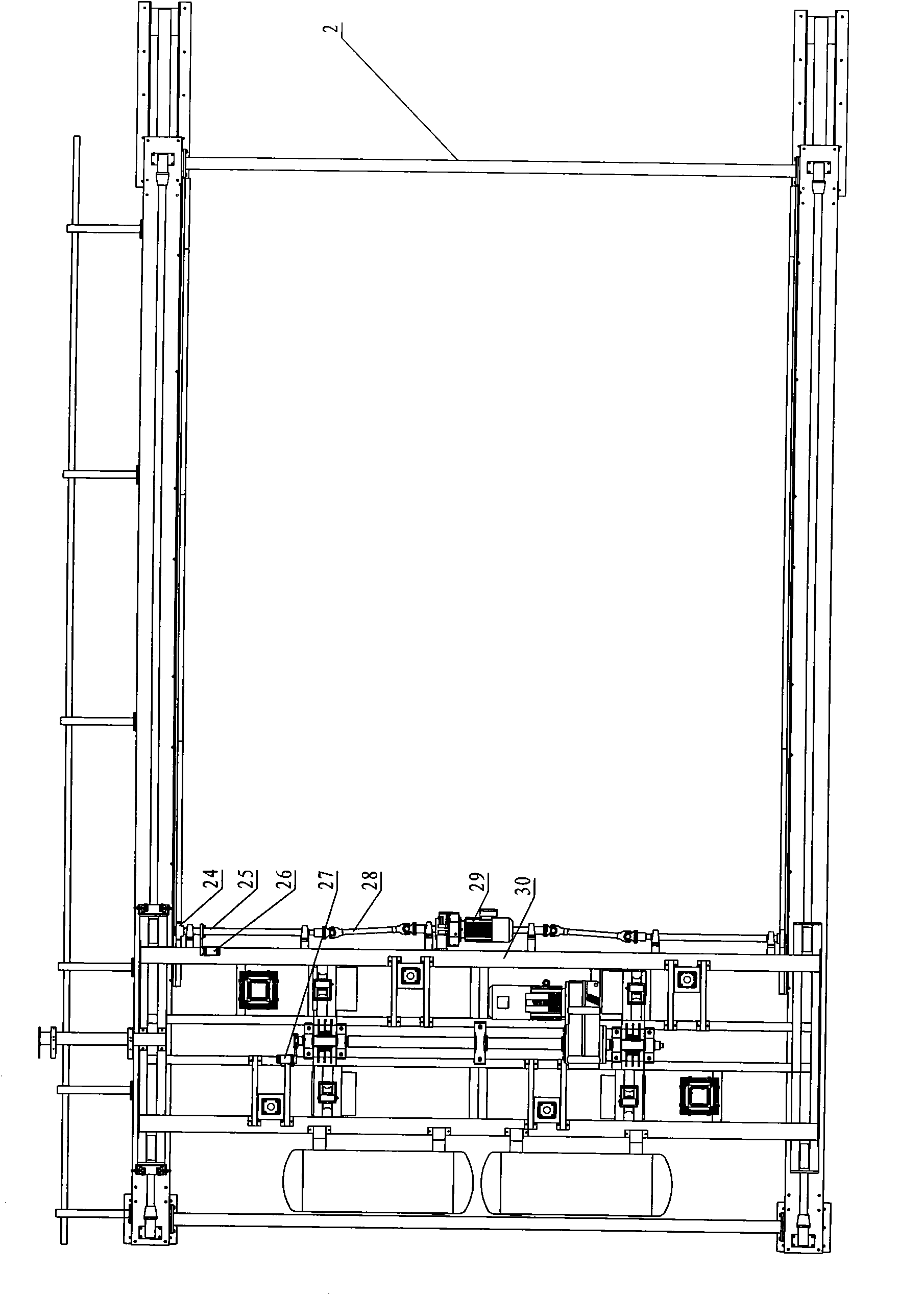

[0014] Referring to the accompanying drawings, the automatic stacking machine is composed of three parts: a frame I, a chuck II, and a lifting trolley III. Frame I: two beams 6 are respectively bolted between the outriggers 1 and 7 on both sides, and the two crossbeam connecting beams 2 are respectively bolted between the two legs 1 and the two legs 7, The guide rail 4 is installed above the H steel of the beam 6, the rack 5 is installed on the angle iron on the inner side of the top of the beam 6, the angle iron is fixed on the steel plate welded by the H steel of the beam 6 with bolts, and the cable bridge 3 is installed on the beam 6 On the H steel on the outside, the cable is suspended on the horizontal C-shaped steel on the cable bridge through the trolley.

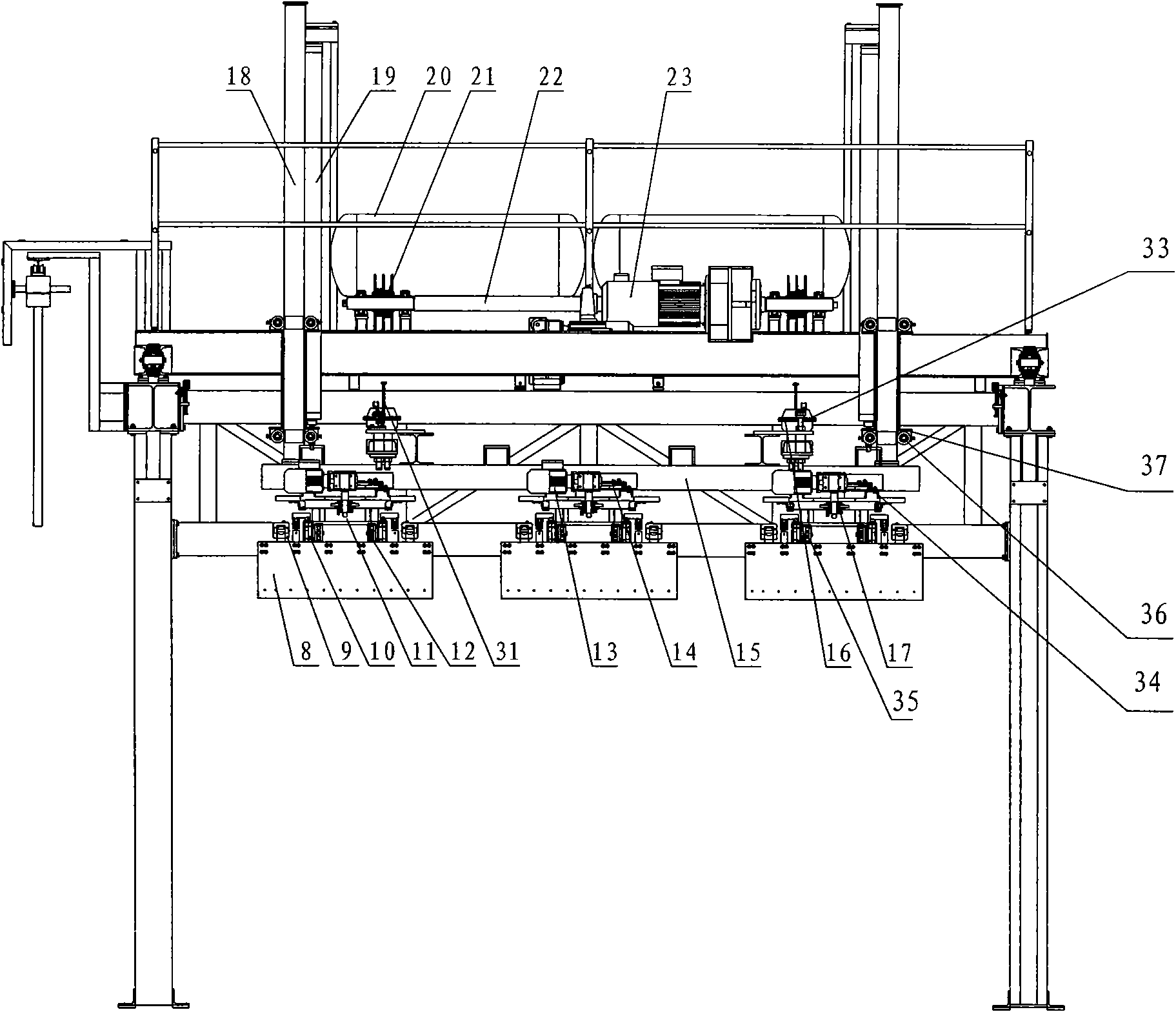

[0015] Chuck II: The chuck bracket 15 is hung directly below the lifting trolley with the hoisting chain and the lifting guide rail 18, the upper end of the hoisting chain is fixed on the hoisting wheel 32 with a pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com