Experimental device for iron ore pellet roasting process

An experimental device and roasting technology, applied in the field of ironmaking production, can solve problems such as difficult thermal data, difficult field experimental research on iron ore pellet roasting process, etc.

Inactive Publication Date: 2011-01-05

UNIV OF SCI & TECH BEIJING

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In actual production, due to the limitations of production equipment and operating conditions, it is difficult for people to conduct field experiments on the roasting process of iron ore pellets

For example, in the roasting process in the rotary kiln, it is difficult to directly obtain the thermal data of the roasting process, and can only be derived and estimated from peripheral data

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

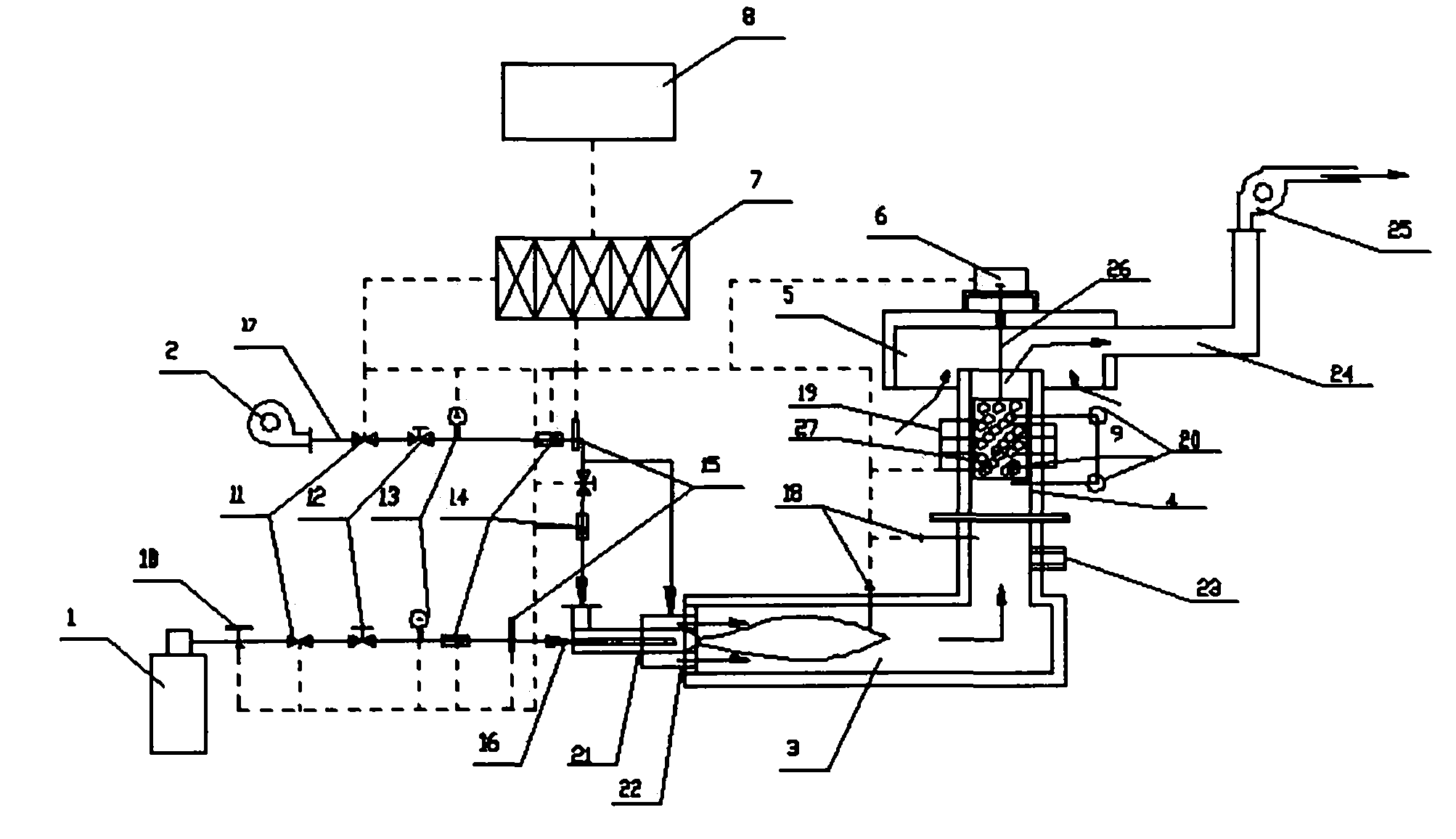

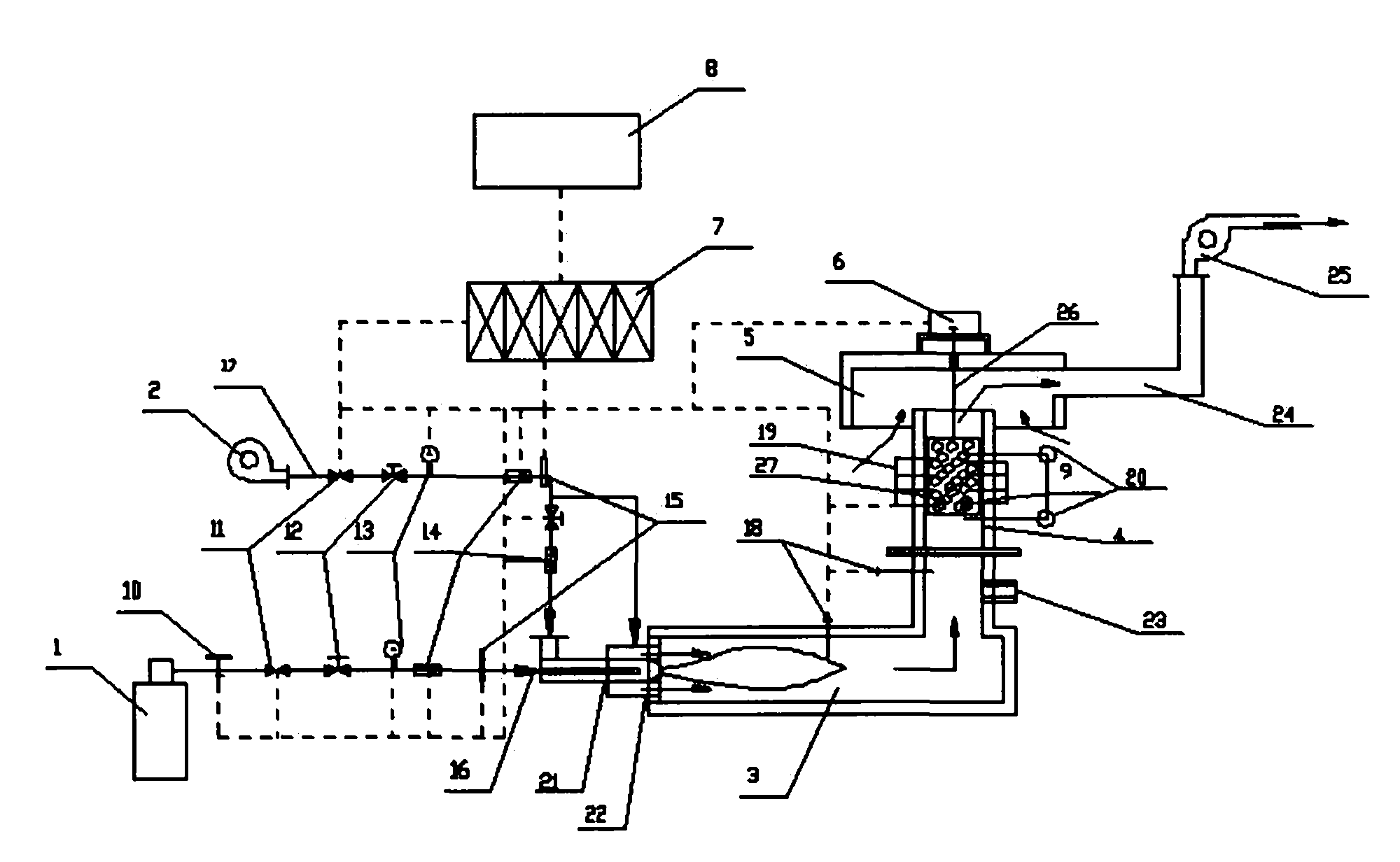

The invention relates to an experimental method and a device for an iron ore pellet roasting process, belonging to the field of iron manufacture production. In order to research the iron ore pellet roasting process in terms of heat transfer, mass transfer, a roasting process mechanism, and the like, the invention discloses the experimental method and the device, wherein the device comprises a gastank, a draft blower, a combustion chamber, a roasting chamber, a smoke exhaust hood, an electronic balance, a PLC system, an industrial computer, a roasting cup, an electromagnetic disconnecting valve, an electrically operated valve, a manual control valve, a pressure gauge, a flow meter, a thermometer, a gas pipeline, an air pipeline, a combustion chamber high-temperature thermocouple, a roasting chamber high-temperature thermocouple, an annular pressure meter, a burner nozzle subassembly, a secondary air annular nozzle, a smoke gas collection hole, a smoke exhaust pipeline, an exhaust blower, a suspension fork, and the like. The device generates smoke gas with different flow speeds, different temperatures and different gases to roast a pellet material layer in a flow-through way, measures and collects relative data, especially the inner temperature distribution of the pellet material layer, and provides important experiment evidence for the theoretical research and the actual production of the pellet roasting mechanism.

Description

An experimental device for iron ore pellet roasting process technical field The invention belongs to the field of ironmaking production. In particular, the invention relates to an experimental device and method for heat and mass transfer and roasting mechanism research of iron ore oxidation pellet roasting process. Background technique In actual production, due to the limitations of production equipment and operating conditions, it is difficult for people to conduct field experiments on the roasting process of iron ore pellets. For example, in the roasting process in the rotary kiln, it is difficult to directly obtain the thermal data of the roasting process, and can only be derived and estimated from peripheral data. The iron ore pellet roasting process includes a series of complex physical and chemical processes such as heat and mass transfer of porous media, gas-solid two-phase flow, and phase transition, involving engineering thermophysics, fluid mechanics, metallurgi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22B1/02C22B1/14

Inventor 冯俊小谢知音张宇果乃涛周圣亮孙鹏飞

Owner UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com