Connecting device between side gate and shell of ram blowout preventer

A technology of ram blowout preventer and connecting device, which is applied in wellbore/well components, sealing/isolation, earth-moving drilling, etc., can solve the problems of high labor intensity, difficult to tighten, and poor sealing, etc., to reduce labor Strength and operating time, reduced production running costs, light connection and opening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

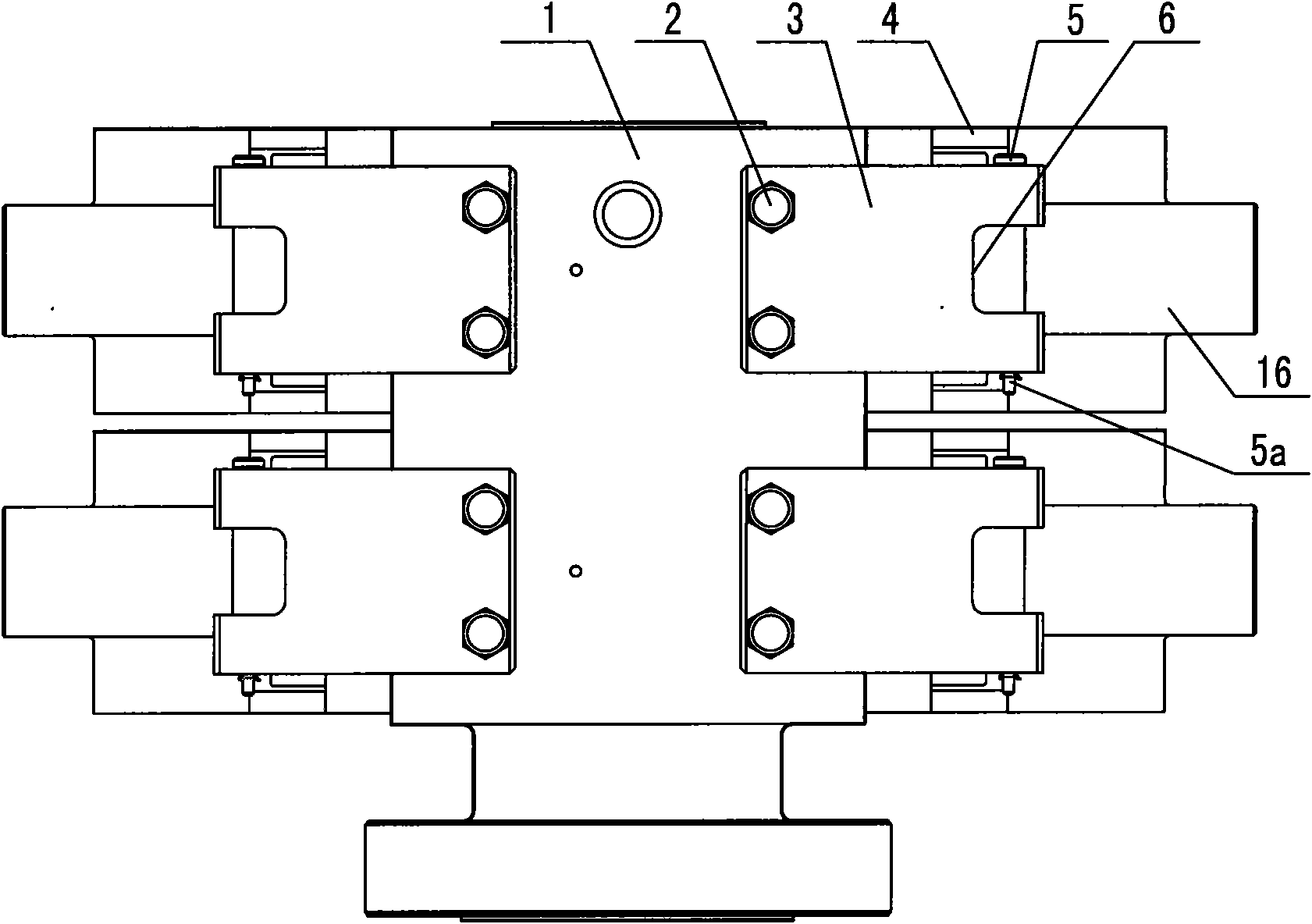

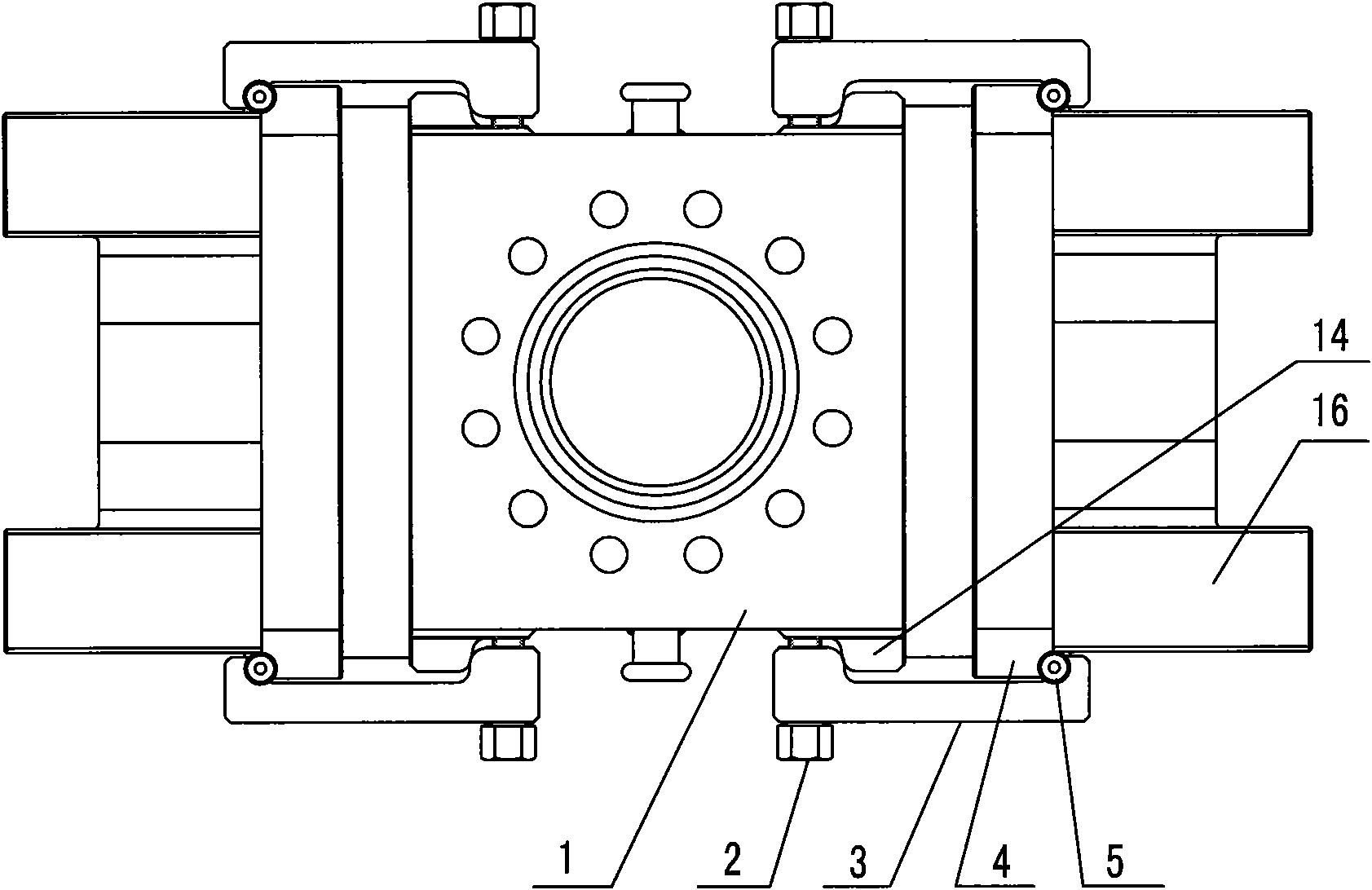

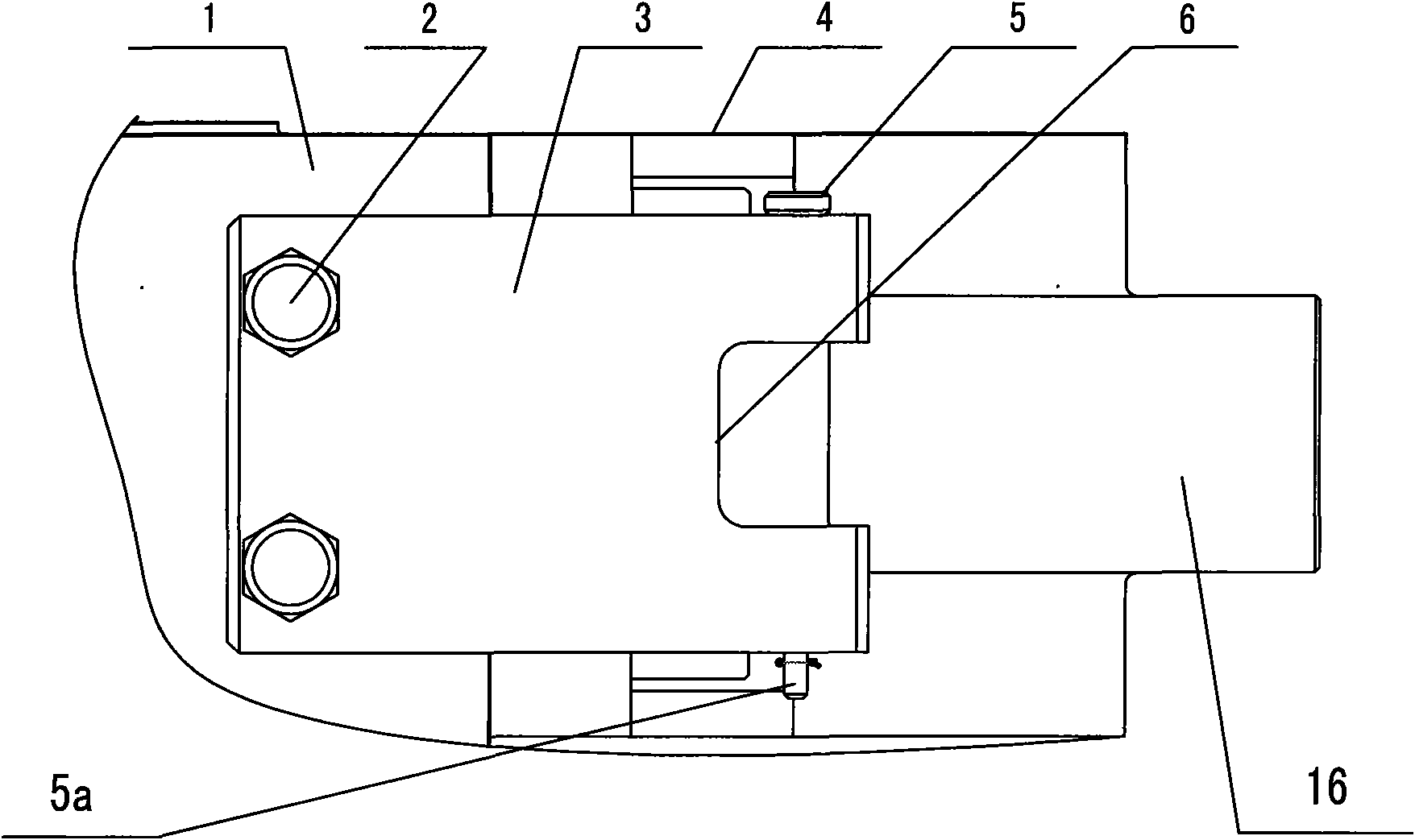

[0020] Embodiments of the present invention are provided below in conjunction with the accompanying drawings: Taking the double ram blowout preventer as an example, the present invention includes a clamping mechanism and a connecting part. The fixed end, the other end is the connecting end, the fastening end is provided with a boss 7 with an arc-shaped inclined surface 8, and a connecting bolt hole 12 is arranged on the boss 7 of the arc-shaped inclined surface 8, and the upper opening of the connecting bolt hole 12 is The outwardly diffused arc surface structure is provided with a pin bolt boss 10 at the connecting end, and a pin bolt hole 11 is arranged on the pin bolt boss 10; The transition point from the cap to the screw is an arc surface structure 13, the tail end 5a of the pin bolt 5 is provided with a lock pin hole 15, and a groove 6 is provided at the connecting end; in order to open or close the side door , to achieve the purpose of replacing and maintaining the dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com