Novel hydraulic pumping unit with high energy saving and low energy consumption

A low-energy-consumption, pumping unit technology, used in mechanical equipment, production fluids, wellbore/well components, etc., can solve the problems of complex transmission, easy damage, high power consumption, etc., to achieve simple transmission, not easy to damage, low power effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

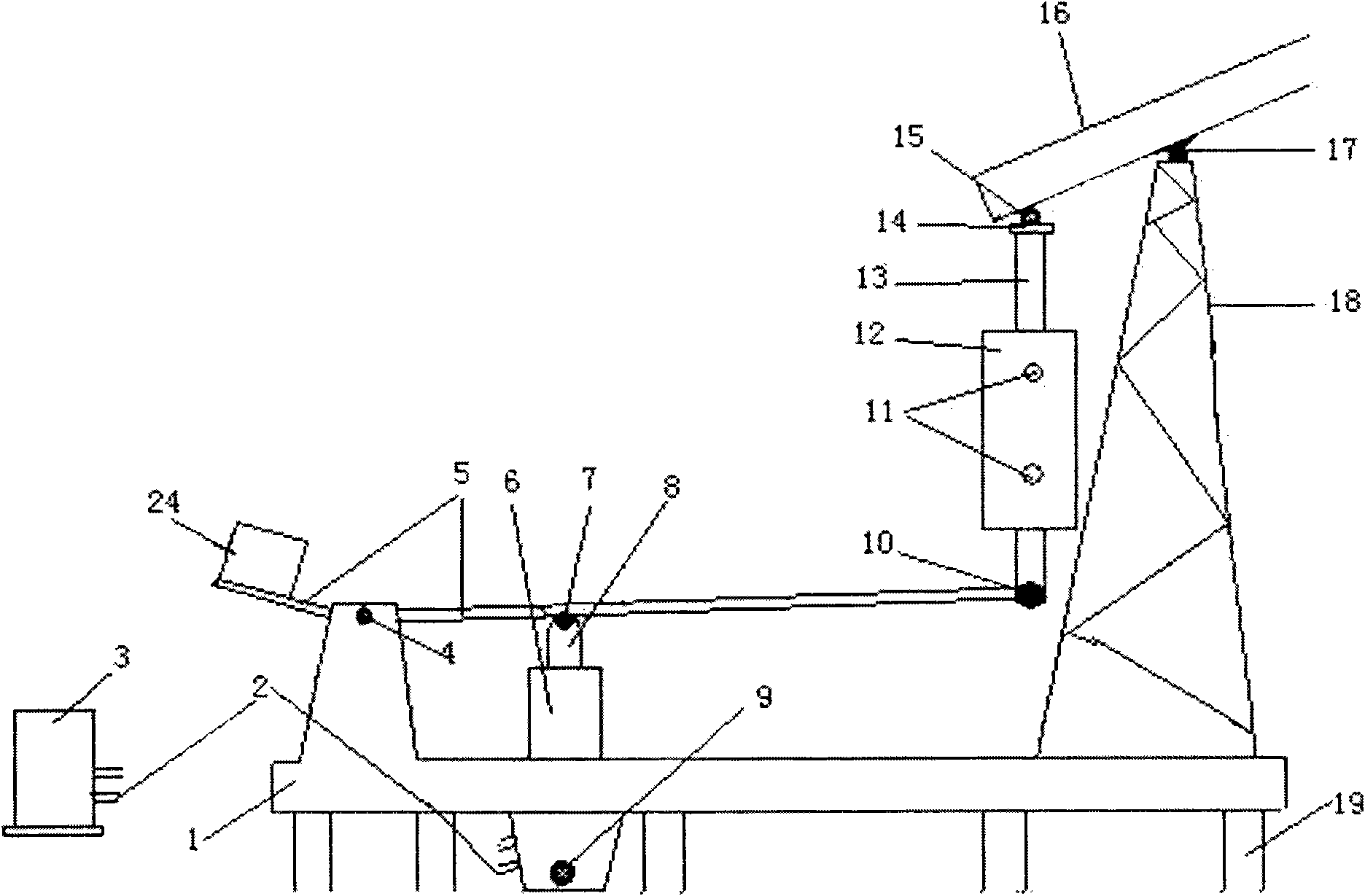

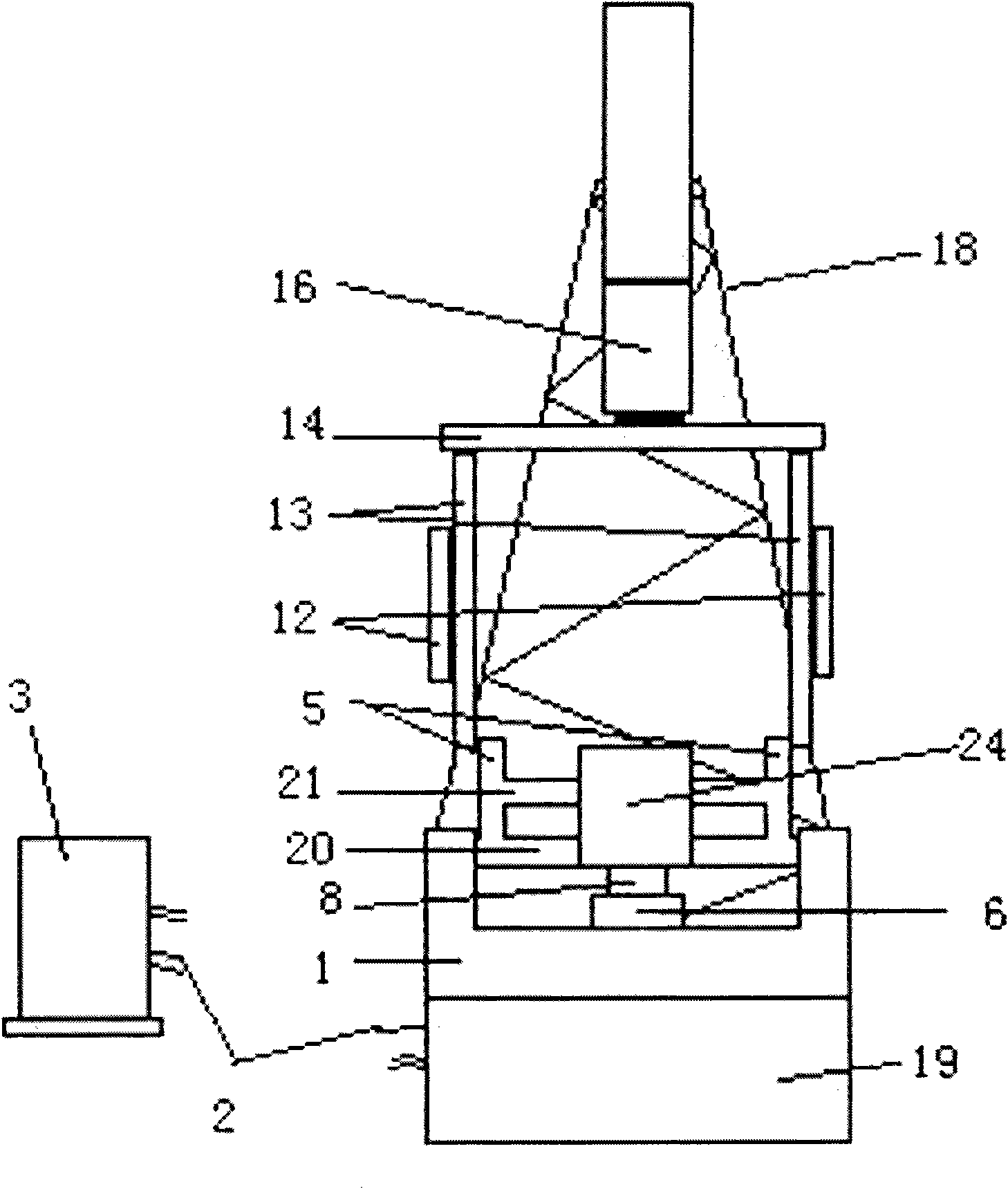

[0013] Referring to the accompanying drawings, a new high-energy-saving and low-energy hydraulic pumping unit mainly includes a beam 16 and its beam bearing 15, a beam 14, a connecting rod 13, a rod bearing 10, a counterweight 12, a connecting rod 5, and a balance body 24 , base 1 and bar bearing 4. A connecting rod 5 is connected to the rod bearing 10 , and the other end of the connecting rod 5 is connected with the balance body and connected with the rod bearing 4 . The top bearing 7 is installed in the middle thereof, and the lower end of the top bearing 7 is connected with a hydraulic cylinder 6 installed on the base and a telescopic rod 8 thereof, the lever bearing 4 is connected with the base 1, and the hydraulic cylinder is connected with the hydraulic control station line. One end of the connecting rod 5 is connected with the rod bearing 10, and the other end is connected with the base 1 by the rod bearing 4. The hydraulic cylinder 6 is connected with the hydraulic co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com