Heat returning closed cooling recirculation system of Brighton scramjet

A technology of engine cooling and scramjet, which is applied to ramjet engines, machines/engines, rocket engine devices, etc., and can solve the problems of scramjet cooling difficulties, fuel supply system gas intake difficulties, and large cooling fuel flow, etc. problems, to achieve the effect of improving energy utilization, good component matching performance, and good heat absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

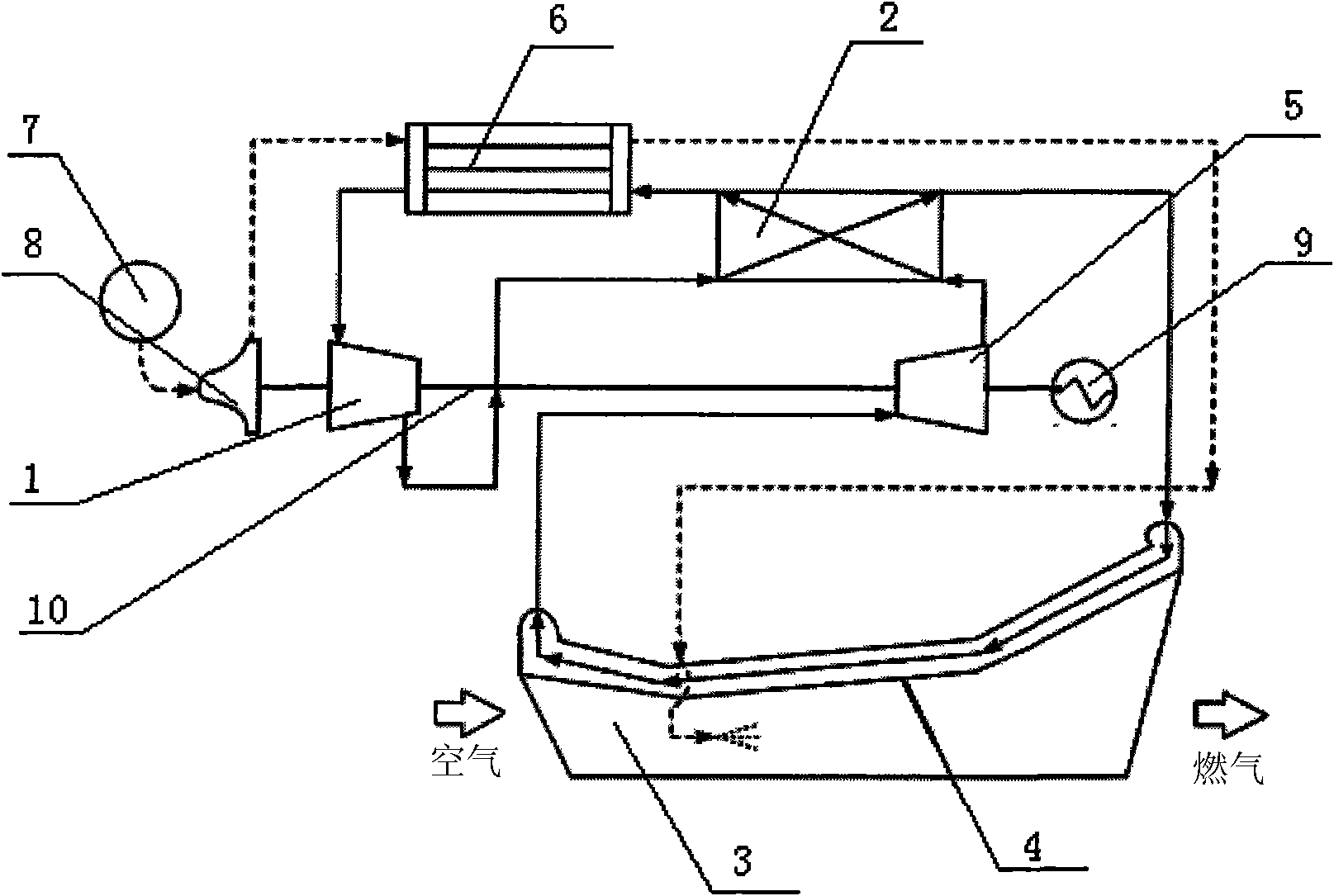

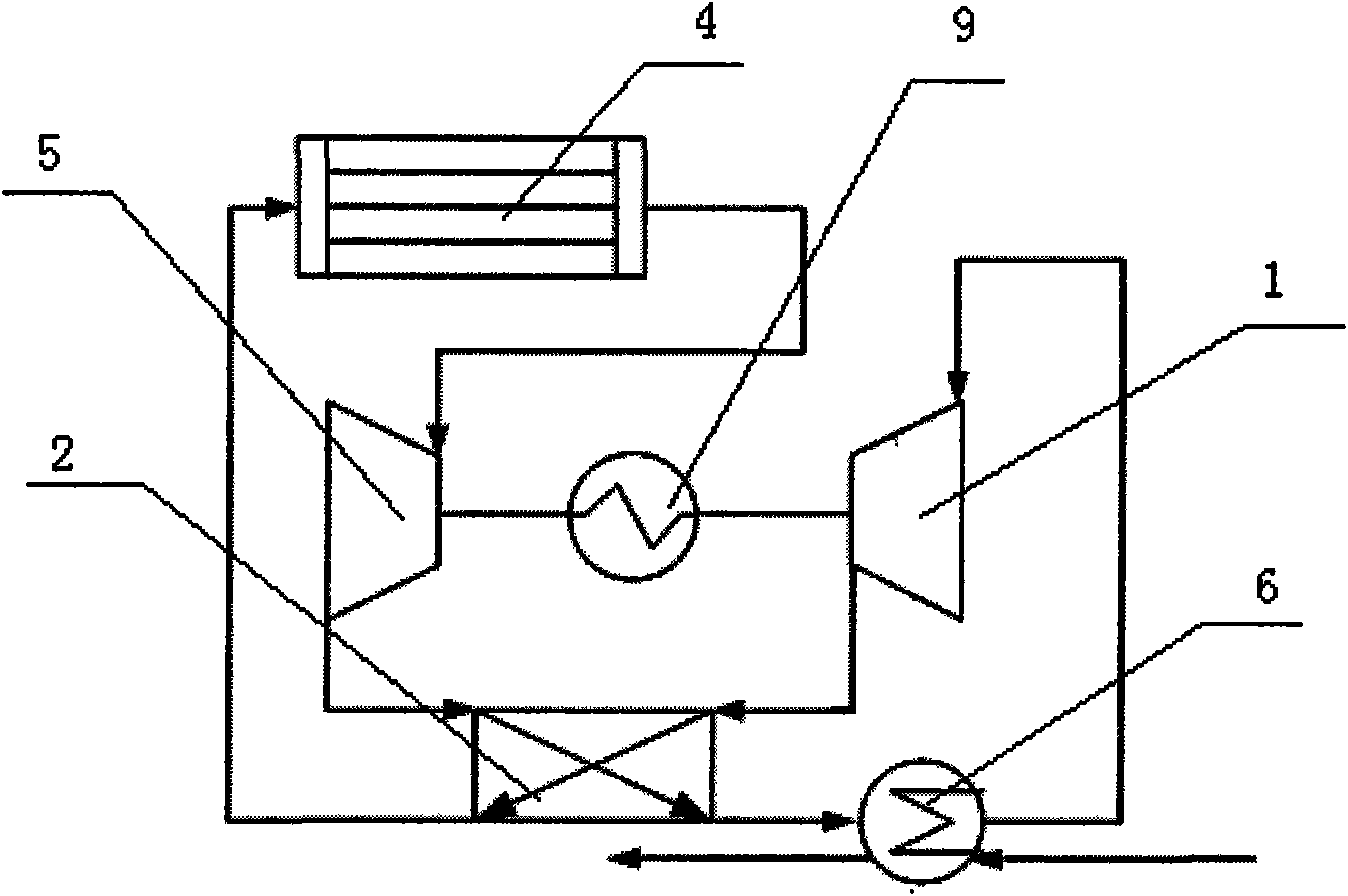

[0009] Specific implementation mode one: combine figure 1 To illustrate this embodiment, the cooling cycle system includes a compressor 1, an engine 3, a cooling passage 4, a turbine 5, a fuel tank 7, a fuel pump 8 and a central shaft 10, and the cooling cycle system also includes a regenerator 2, a heat exchanger Heater 6 and generator 9, one end of described central shaft 10 is connected with generator 9, and the other end of described central shaft 10 is connected with air compressor 1 and fuel pump 8 respectively, and described turbine 5 is contained in generator 9 and On the central axis 10 between the compressors 1, the cooling channel 4 is arranged on the outer wall surface of the upper part of the engine 3; the output end of the compressor 1 is connected to the cold side input end of the regenerator 2 through a pipeline, The output end of the cold side of the regenerator 2 is connected to the input end of the cooling passage 4 through a pipeline, the output end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com