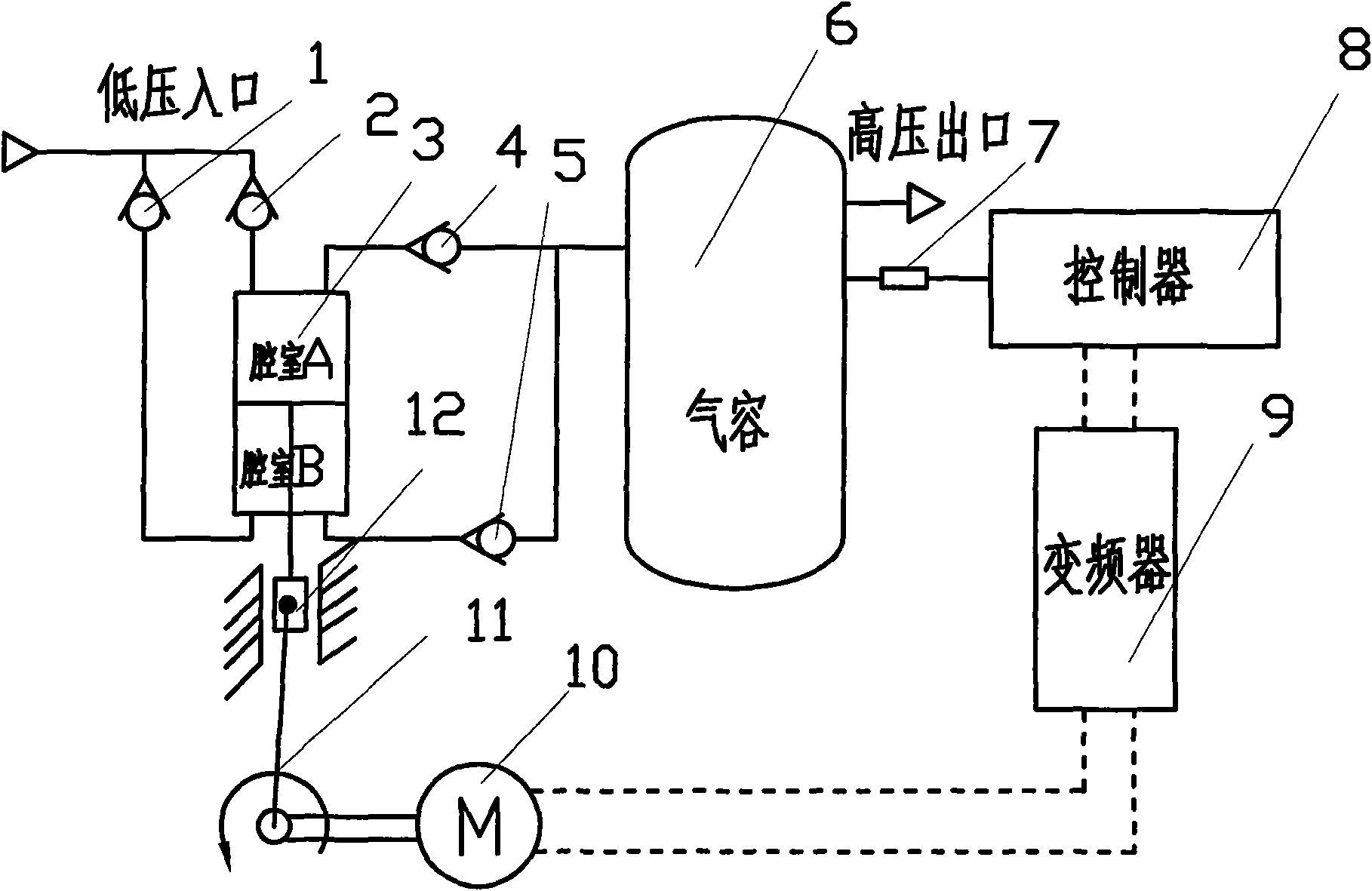

Bidirectional supercharging-type electric gas supercharging device

A gas supercharging, electric technology, applied in the direction of fluid pressure converter, mechanical equipment, etc., can solve the problems of limited application, small displacement of supercharger, low system efficiency, etc., and achieve the effect of reducing frequent start and stop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] 1. The gas is filled into the chamber B of the cylinder (3) from the low-pressure gas source through the check valve (1) and the motor (10) drives the shaft (11), the piston pressurizes the gas in the chamber A, and the chamber A The medium-high pressure gas is charged into the gas container (6) through the one-way valve (4), and finally the high-pressure gas is output to the gas-consuming equipment. When the piston of the cylinder (3) reaches the upper end of the stroke, it is reversed under the action of the shaft (11), and the gas is filled into the chamber A from the low-pressure gas source through the one-way valve (2), and the motor (10) jointly drives the crankshaft (11) , the piston pressurizes the gas inside the chamber B of the cylinder (3), the high-pressure gas in the chamber B is filled into the gas container (6) through the check valve (5), and finally the high-pressure gas is output to the gas-consuming equipment. This is one working cycle of the supercha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com