Split type spherical outer ring roller bearing

A spherical outer ring and roller bearing technology, applied in the field of bearings of rotating parts, can solve the problems of reduced bearing service life, damage to mechanical equipment, uneven bearing force, etc. uniform force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

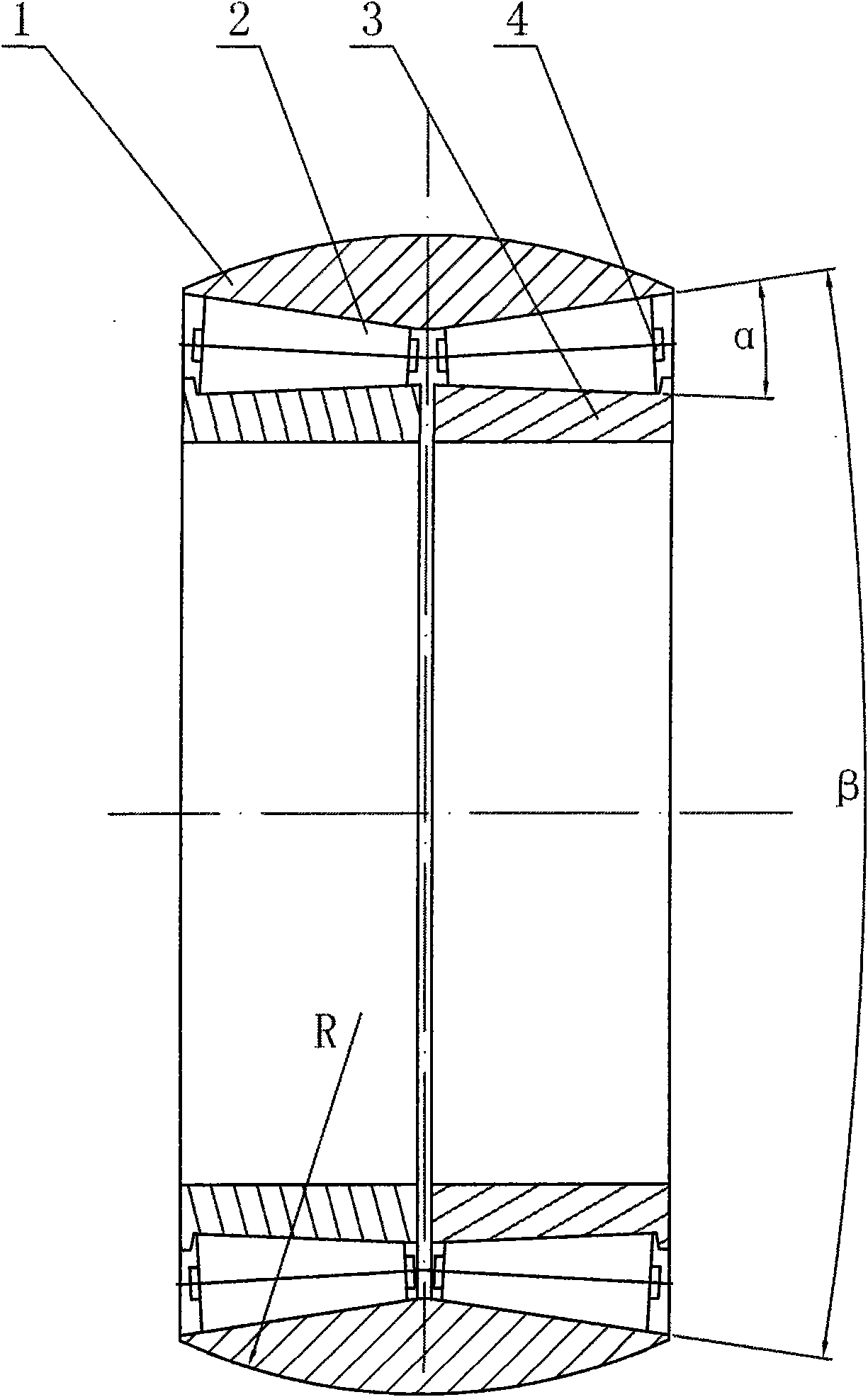

[0011] exist figure 1 Among them, the split spherical outer ring roller bearing of this embodiment is composed of a bearing outer ring 1, rollers 2, bearing inner ring 3, and a roller frame 4 connected.

[0012] Two bearing inner rings 3 are installed in the bearing outer ring 1. The outer surface of the bearing outer ring 1 is a spherical surface with a spherical radius R of 5000mm. The inner surface of the bearing outer ring 1 is a conical surface with a cone angle of β. The bearing inner ring The inner surface of 3 is a cylindrical surface, and the outer surface of bearing inner ring 3 is a conical surface, and the cone angle is α. The inner surface of the bearing outer ring 1 and the outer surface of the bearing inner ring 3 form two interconnected ring-shaped conical spaces. Two roller frames 4 are installed in the annular circular platform space between the inner surface of the bearing outer ring 1 and the outer surface of the bearing inner ring 3, and rollers 2 are ins...

Embodiment 2

[0014] In this embodiment, the outer surface of the bearing outer ring 1 is a spherical surface, the radius R of the spherical surface is 10mm, and the shape of the roller 2 is a truncated cone. The specific geometric shape of the roller can be determined by the conventional design in the mechanical design manual according to the bearing capacity. The specific number of columns 2 is determined according to the outer diameter of the inner ring 3 of the bearing. The specific data of the cone angle α of the outer surface of the bearing inner ring 3 and the specific data of the cone angle β of the inner surface of the bearing outer ring 1 are determined by the conventional design in the mechanical design manual according to the geometry of the roller. The geometric shapes of other components and the coupling relationship of the components are the same as those in Embodiment 1.

Embodiment 3

[0016] In this embodiment, the outer surface of the bearing outer ring 1 is a spherical surface, and the radius R of the spherical surface is 10000mm. The shape of the roller 2 is a truncated cone. The specific number of columns 2 is determined according to the outer diameter of the inner ring 3 of the bearing. The specific data of the cone angle α of the outer surface of the bearing inner ring 3 and the specific data of the cone angle β of the inner surface of the bearing outer ring 1 are determined by the conventional design in the mechanical design manual according to the geometry of the roller. The geometric shapes of other components and the coupling relationship of the components are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spherical radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com