Tube furnace burner

A technology of burners and tube furnaces, applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems of harsh operating conditions, high energy consumption of tube furnaces, pollution of combustion products, etc., and achieve strong flame rigidity, The effect of stable and reliable combustion and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

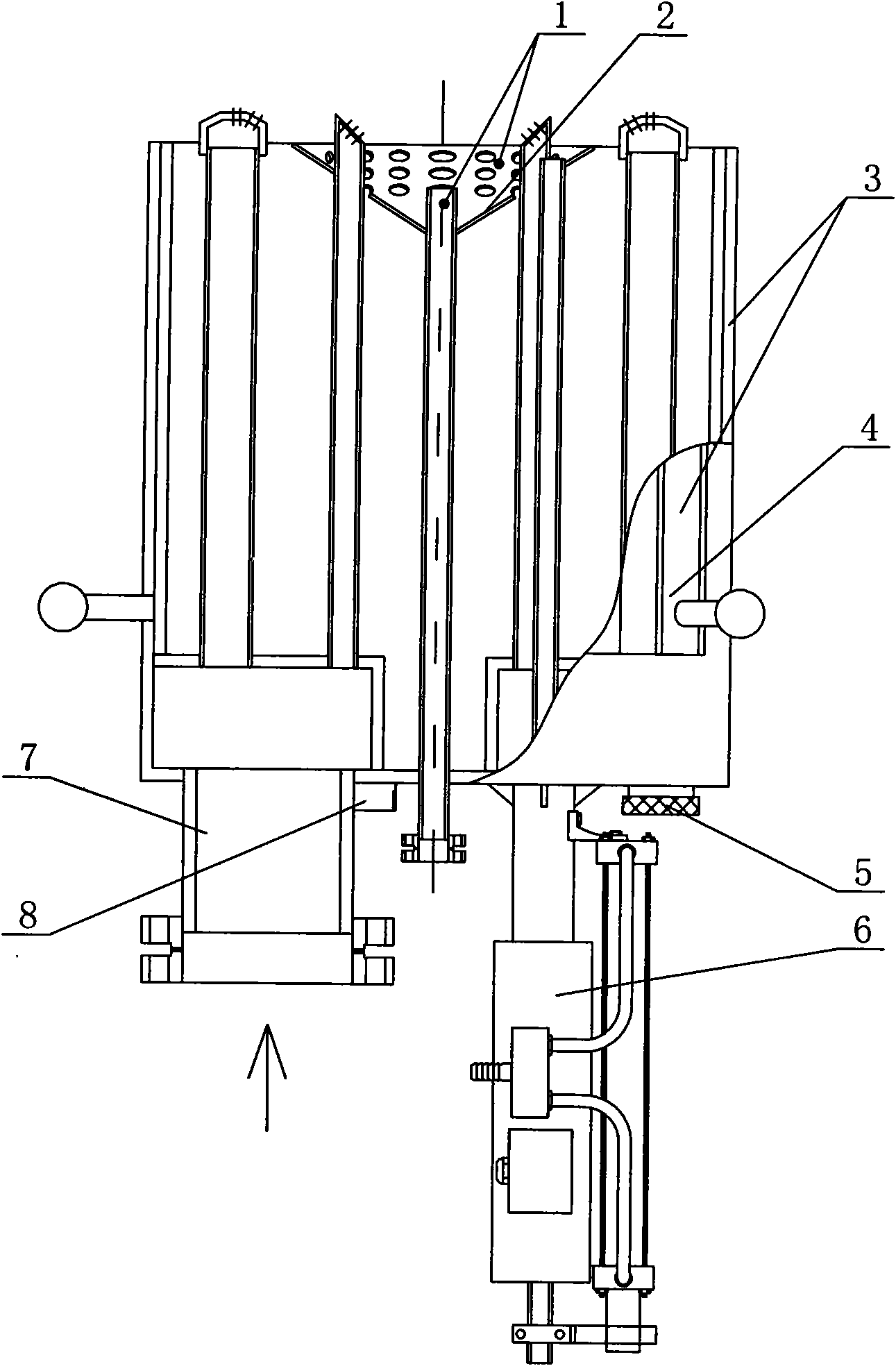

[0027] See figure 1 , tube furnace burner, including ignition nozzle 1, stable combustion cover 2, outer wall 3, regulating damper 4, fire viewing hole 5, pneumatic propeller 6, intake pipe group 7, fire detection installation pipe 8, and the upper part of the burner There is an ignition nozzle 1 and a stable combustion cover 2, the lower part is provided with an intake pipe group 7 and a pneumatic propeller 6, and the outer wall 3 is provided with an adjustable damper 4 that can adjust the air intake. The bottom of the burner is provided with a fire detection installation pipe 8 and a fire viewing hole 5 .

[0028] The functions of each component of the tube furnace burner are described as follows:

[0029] Regulating damper 4: mainly used to adjust the air distribution volume;

[0030] Pneumatic thruster 6: used to advance and retreat the ignition gun, advance the ignition gun when igniting, and withdraw the ignition gun after ignition, which effectively protects the ignit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com